Rocketman wrote:I print on glass so that shaves off height right there. Not sure if that brings be below the 6", or if the height is a bit more generous than the XY.

you should know exactly how tall you can go..

lower the bed manually until it will not go any lower and find out exactly what the Z height is.

If your slicing software has a place to enter that value, do so

If it does not, you still should know exactly what it is - make a note of it somewhere.

personally, i do not lower the bed anymore than where it ends up when the print is finished. I have not found a need to do this.

I have an ending script that homes the X & Y axis, so the hotend is out of the way, but that is it. That is all I have ever needed.

For something like this maraca - you do not want to use the built in slicer supports. it will put them inside the bulb, regardless of the settings.

Add supports to the outside of the model in a program like Meshmixer, save the new supported model with a different name (ie: maraca_with_supports) then import & slice with support settings turned off.

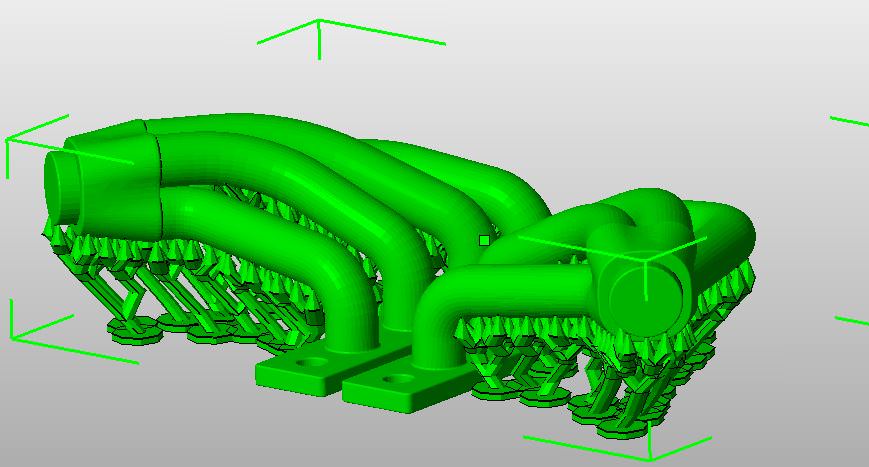

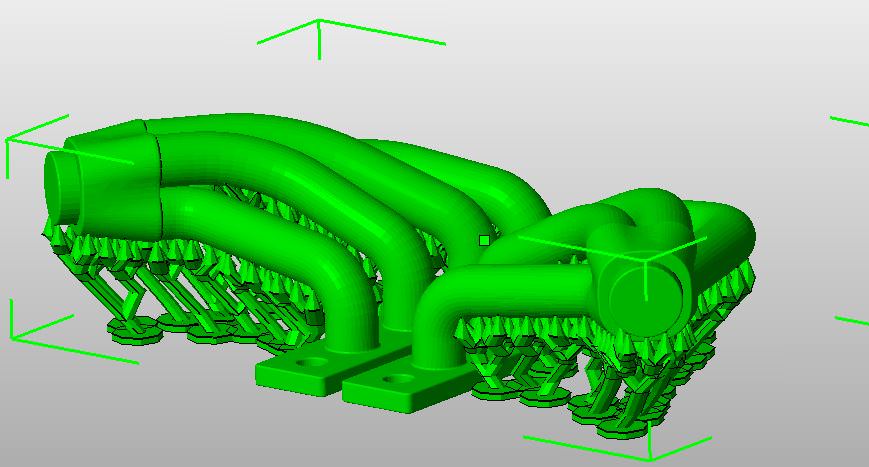

this is an example of Meshmixer supports..

These are quite easy to remove, and leave very little evidence they were there.

SD4 #1 & #2 - Lawsy carriages, E3D v6, Rumba controller board, mirror bed plate, X motor fan, upgraded PSU & Mica bed heater

SD4 #3 - in the works ~ Folgertech FT-5, rev 1

Printit Industries Beta Tester - Horizon H1