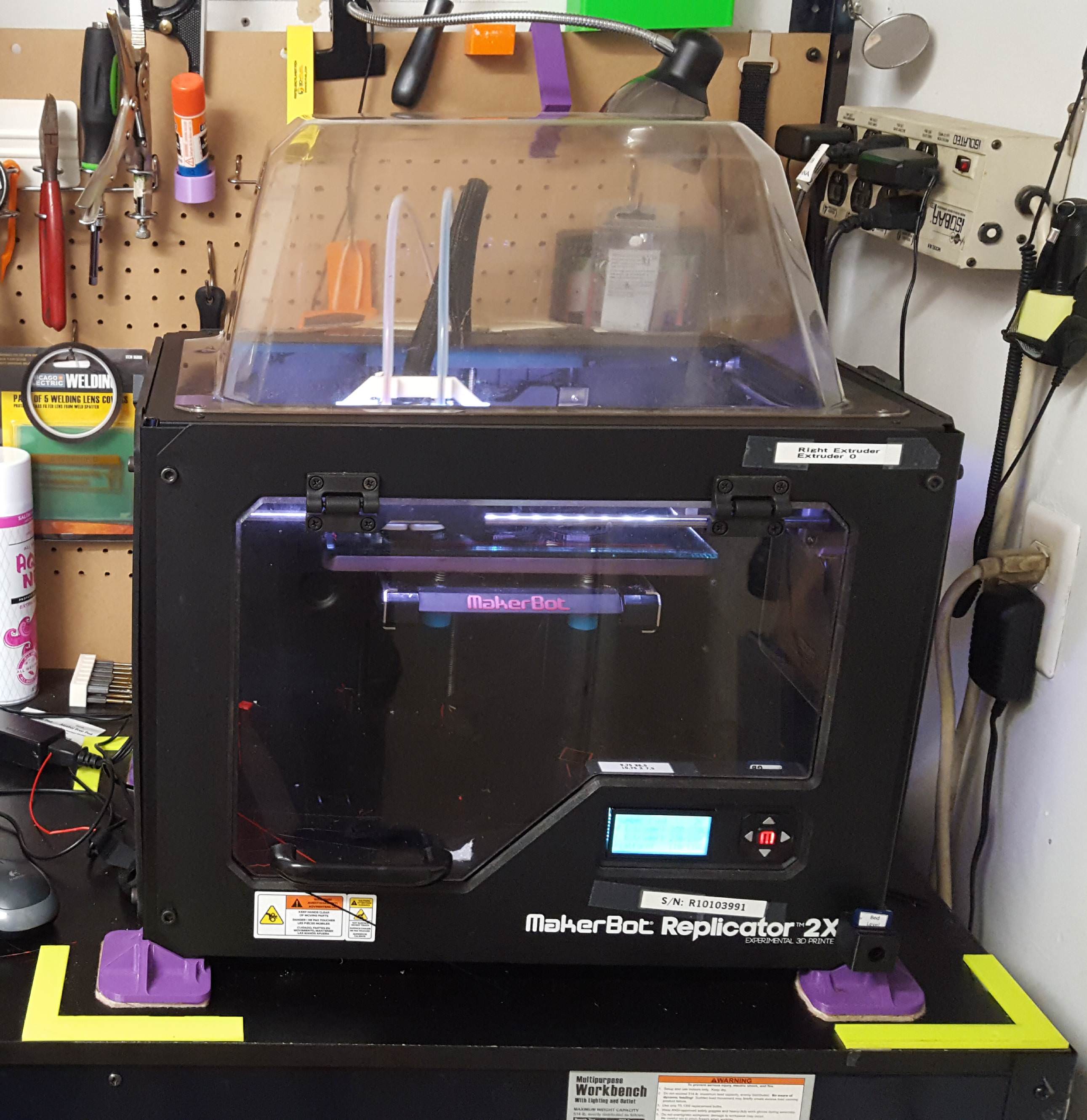

Topic: Modifying my 3d printer bench

I have a Makerbot replicator 2X and both rolls mount to the back of the machine.

the bench is 24" front to back and it makes it a pain to change rolls.

the printer is 18" front to back including rolls

so i bought a pair of 20" drawer slides and a lazy susan so I can pull the printer out and turn

it to work on it.

Thanks

Dale