Topic: New to printing - DaVinci Mini

Hello there,

Referred here by a friend and though I would ask for a little help as I am new and have a limited vernacular at the moment.

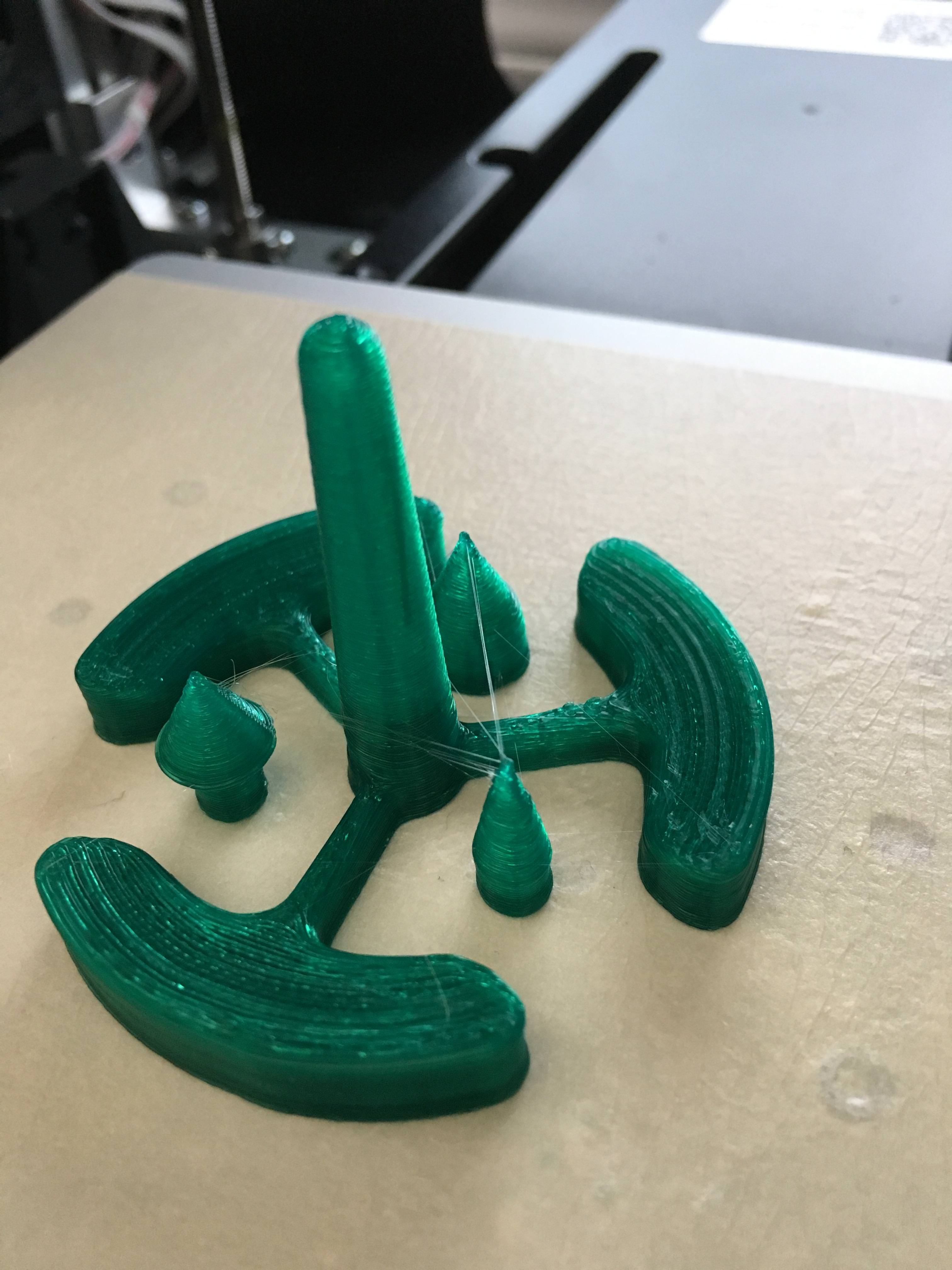

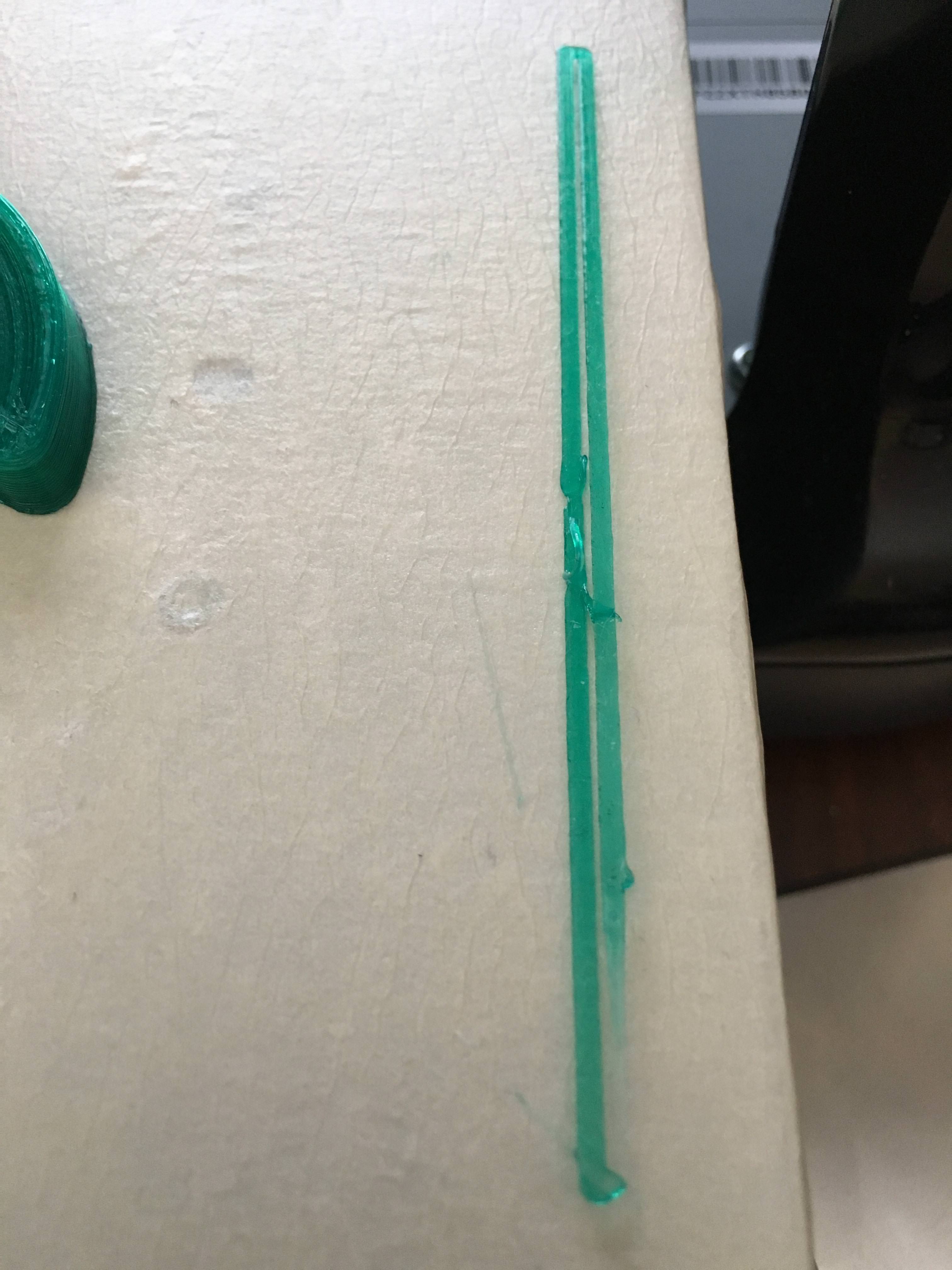

I ran the first spool of filament through the DaVinci Minimaker and had great success with things sticking the the adhesive tape and printing right from the get go. However I have replaced it with a clear-green filament from XYZ and have had issues with the print lifting or shifting that appear to be from float on the bed.

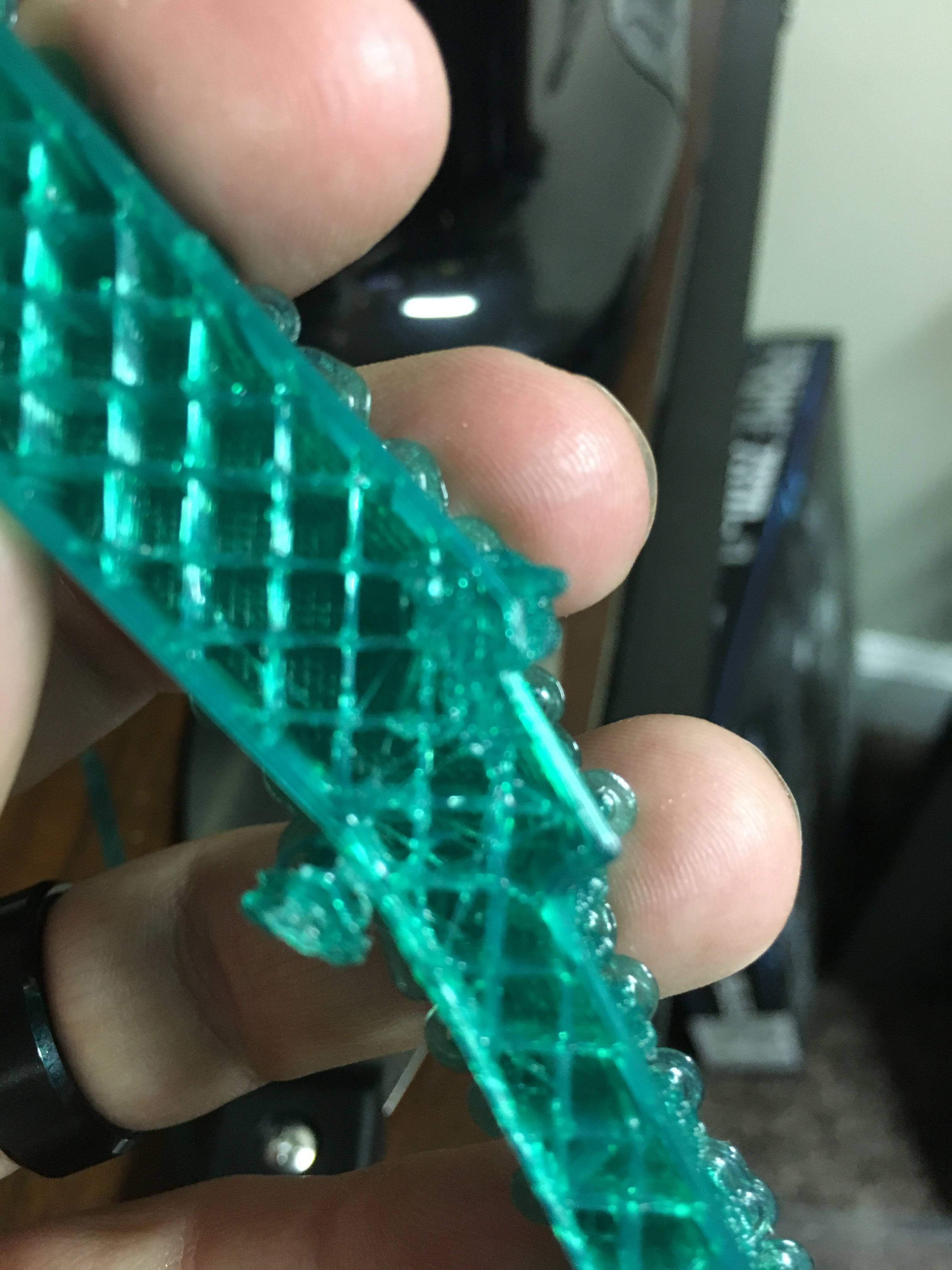

I'm also attempting to print a mask I cut into pieces, but had to generate supports for (using Meshmaker) this print pretty well with minimal drips (?) where support was unavailable or somewhat malformed by the printer in the demo spool (clear-yellow 100m) but the clear-green (200m) will not hold and seems to be 'runny'. Like it leaves wisps and trails behind when moving point to point where the yellow spool did not.

Any thoughts, suggestions, advice is appreciated.