Topic: An Interesting Y axis problem

TL;DR - Y axis on multiple 2GT Solidoodles does this. I replaced lots of stuff. What have I missed?

Hey gang!

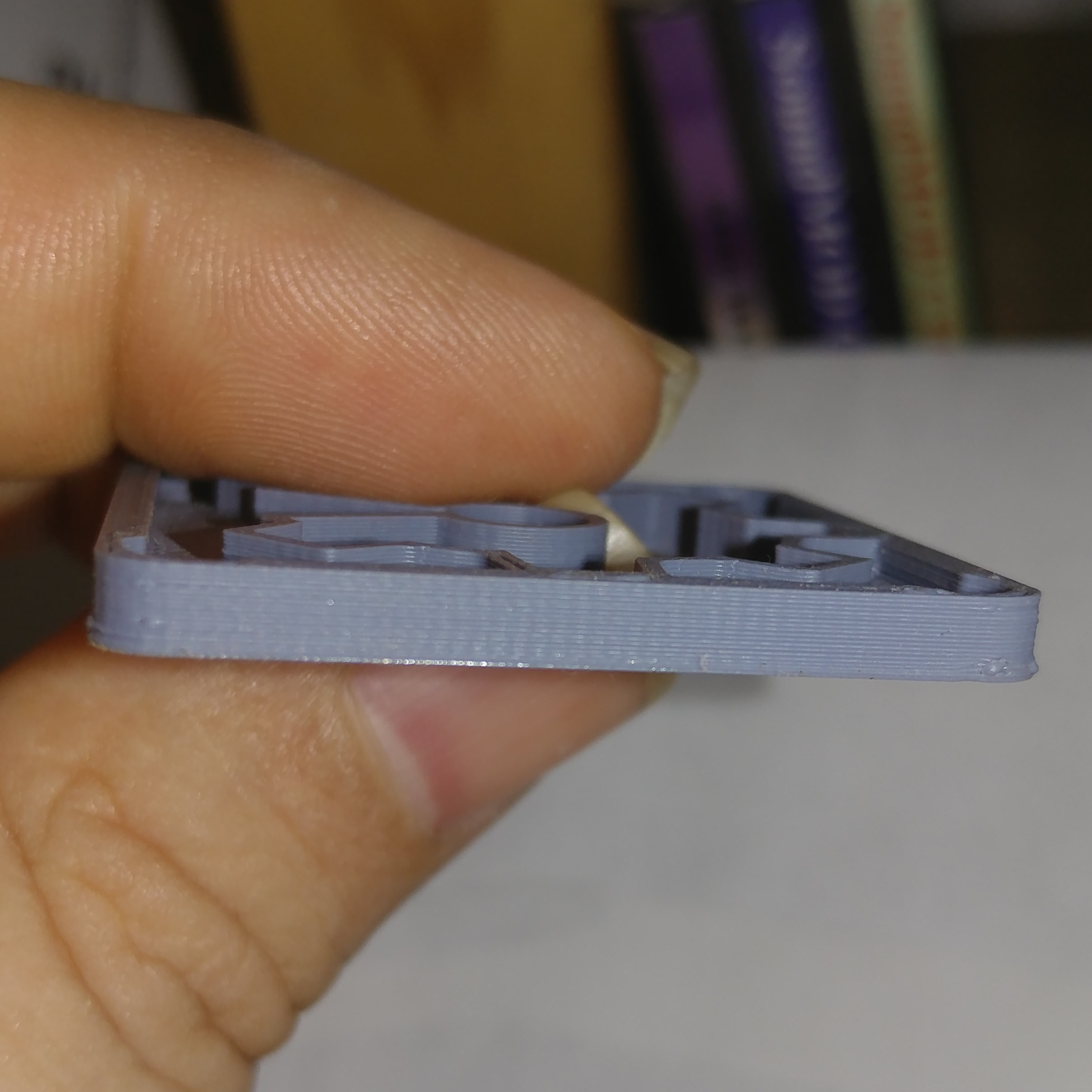

I've been working on a very frustrating problem on my SD3s and SD4s for a while. A synopsis is in this picture:

There are small, periodic waves along the Y axis of any print at any size. The period, according to my caliper is about a millimeter (0.52mm PtP). These also show up on curves and diagonal sections. This ruins any artistic print.

The X axis is unaffected.

I first found this on my SD3, and later discovered through examination that my GT2-upgraded SD4s are doing it too (The SD4s only print natural ABS for working parts, so I never bothered to -look- until recently).

Things I've tried (soft/firmware) on the affected SD3:

Changed print speeds (from slow to fast) in Slic3r and S3d

Changed acceleration and jerk settings

Changed microsteps from 16 to 8 (in hardware and firmware)

I changed those back when it had no effect, and it was clear this wasn't just extreme ringing and the resistors on the Stepstick clones and Pololu showed these were probably not 'Stepstuck' issues that A4988 drivers can supposedly have.

I then began replacing hardware on the SD3:

Changed motor driver to a Pololu brand A4988 driver

Switched to a known-good RepRapDiscount RAMPS 1.4 and Taurino Power from another printer

Tuned the motor driver, and also ran it deliberately below and above optimal with no change

Replaced all three belts and ensured proper tension (I'm glad I had some Gates belting lying around, but the loop belt isn't name-brand)

Replaced the 2GT idlers and all three 6mm bore pulleys

Replaced the 6mm OD Y axis drive rod

Replaced the Y axis motor with a known good Kysan

Replaced the 5mm bore pulley on the Y axis motor

Replaced all four LM8UU bearings and verified quiet and smooth operation

Replaced carriages with Boz' tightened ones (I was planning to do this anyway)

The only thing I haven't replaced are the Y axis linear rods. The Y axis rods are smooth and scratch free Misumi ones on each printer, with just a thin sheen of lubricant.

I'm confident it's not an extruder artifact One of the SDs showing this issue is running a Mk6 with an E3D v6, and another is running an E3D Titan + V6 combo. There's enough difference between the two that, if extrusion was the issue, it would have shown differently on one and not the other just because the Titan is geared.

The only theory I have left is this:

The only non-printed parts that aren't common between the upgraded Solidoodles and my artifact-free i3 and MendelMax are the 6mm bore 2GT pulleys and 2GT loop belt. Yet I've managed to discern no wobble in any of them, and you'd think that if all three wobbled, the period wouldn't be so distinct, since they'd have the same period but be off in terms of when it wobbles (they are not aligned).

So, I have to ask: What have I missed? I've replaced the Y axis almost entirely, upgraded certain parts in the process to make sure it wasn't a QC issue with them (Motor, stepper driver, belts, controller), and I'm pretty well at the end of my wits.

(Edited to include loop belt in non-common parts)