Topic: print gcode files to miniMaker

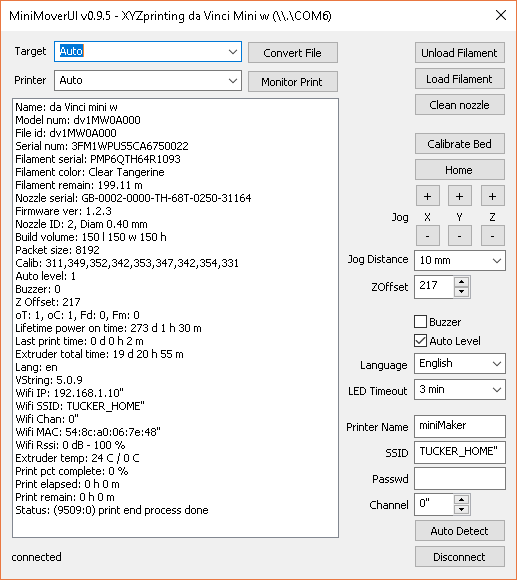

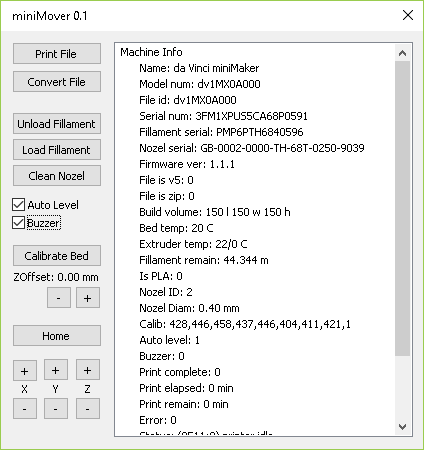

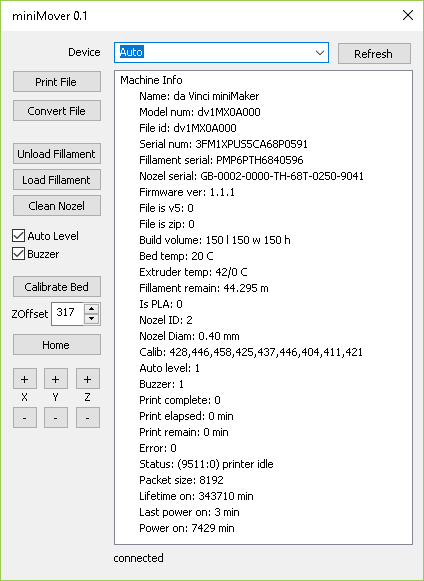

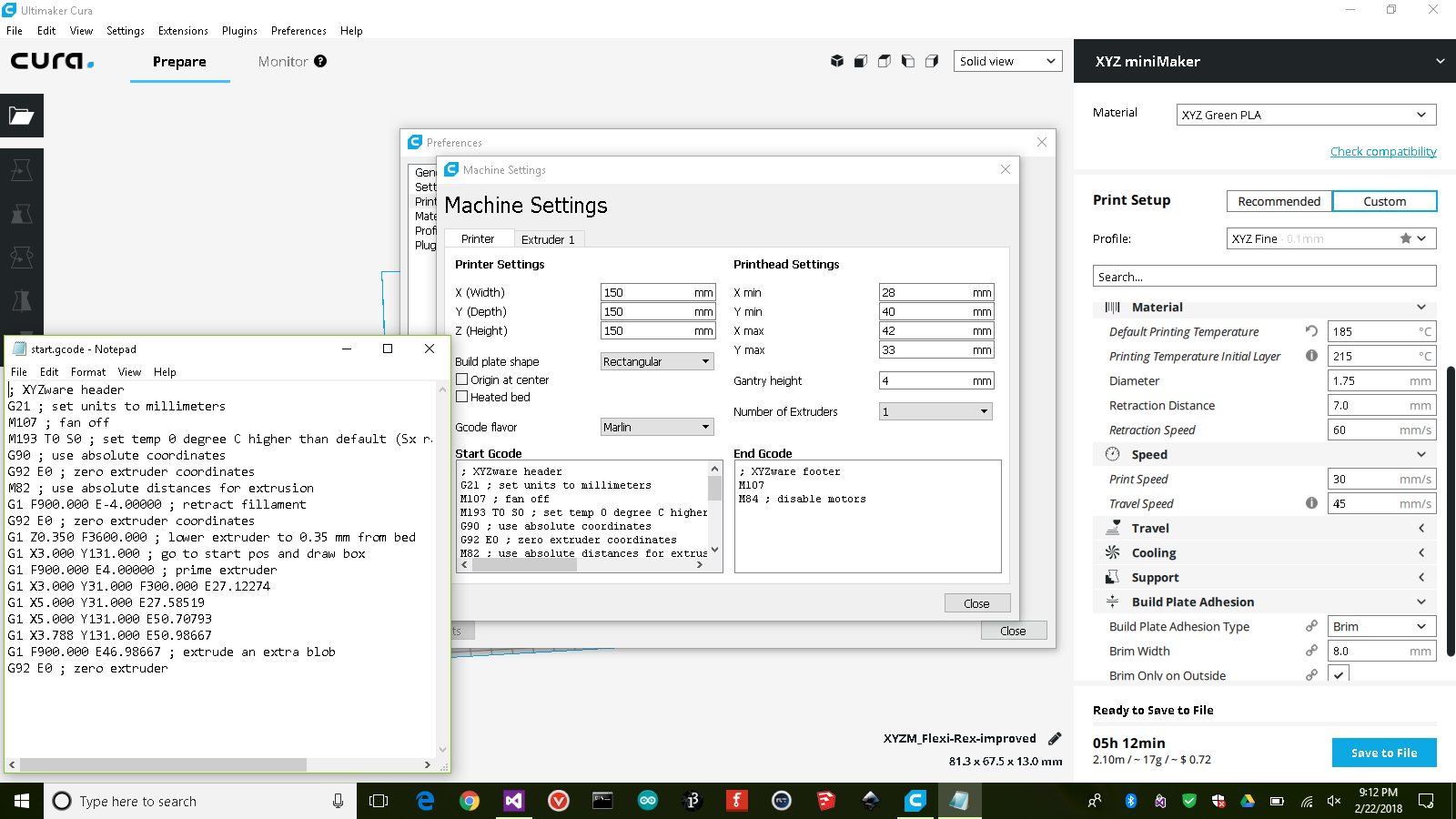

I made a new utility called miniMover that lets you send gcode files to a miniMaker, or any other XYZ 3D printer that uses the V3 serial protocol. This includes the Jr line, the new Pro line and the wireless mini and unreleased micro. This is inspired by the various threedub projects but is based on a fresh reverse engineering of the protocol.

This comes in both a command line and UI variant.

You can download the utility and source code from here https://github.com/reality-boy/miniMover. The exe is also attached below.

To use just pass a file to minimover or apply one of these arguments for more advanced control.

file - print file if .gcode, otherwise convert to gcode if .3w

-d devName - set serial port device name or wifi ip address, -1 auto detects port

-po devName - set serial port device name, -1 auto detects port

-c file - convert file

-p file - print file

-f file - upload firmware, experimental!

-r - print raw status

-s - print status

-? - print help message

* The following only work on machines that lack an LCD *

-a+ - enable auto level

-a- - disable auto level

-b+ - enable buzzer

-b- - disable buzzer

-cl - clean nozzle

-ca - calibrate bed

-h - home printer

-l - load filament

-o num - increment/decrement z offset by num

-u - unload filament

-x num - jog x axis by num, or 10 if num not provided

-y num - jog y axis by num, or 10 if num not provided

-z num - jog z axis by num, or 10 if num not provided

This works with the following printers over a USB connection (no wireless support yet).

da Vinci nano

da Vinci nano w

da Vinci mini w

da Vinci mini wA

da Vinci mini w+

da Vinci miniMaker

da Vinci Jr. 1.0

da Vinci Jr. 1.0 Wireless

da Vinci Jr. 1.0A

da Vinci Jr. 1.0 Pro

da Vinci Jr. 1.0w Pro

da Vinci Jr. 1.0 3in1

da Vinci Jr. 1.0 3in1 (Open filament)

da Vinci Jr. 2.0 Mix

da Vinci 1.0 Pro

da Vinci 1.0A Pro

da Vinci 1.0 Pro 3in1

da Vinci Super

These printers use an older communication protocol so can't communicate with them but we can still convert gcode to 3w files and use XYZWare to send it to the printer.

da Vinci 1.0

da Vinci 1.0A

da Vinci 1.0 AIO

da Vinci 1.1 Plus *** May partially work over usb

da Vinci 2.0 Duo

da Vinci 2.0A Duo

The da Vinci Color uses a different file format and communication protocol and is also not supported.

Updates:

1/12/18 - fix crash in release build

1/15/18 - add support for pause/resume/cancel of print job, attempt to set print length properly in 3w file

2/19/18 - Initial support for windows UI, needs work.

2/24/18 - Cleanup to UI, it is much better behaved now.

3/07/18 - Better handling of status string, fixed zoffset issue

3/11/18 - Improved serial handling

3/18/18 - Support older zip based .3w file format

3/25/18 - Fix print bug, better debug logging

5/19/18 - Released 0.9, many bug fixes, set new parameters

10/05/18 - Released 0.9.5, initial wifi support and linux/mac