I can't help but wonder if Simplify3D might just work better than XYZware anyway... however... it's expensive... and I don't see a 30 day trial or anything.

XYZ Support have still not responded to the ticket opened Wednesday. The supplier (eBuyer) refuse to issue a returns number until XYZ Support have said I need to return the printer. I have to decide if I want that fight, or whether I just continue to solve this myself, and if I can't, get a different printer from somewhere else (Creality CR10 from Gear Best maybe?)..

I'm not tied to using XYZ filament - I have a little NFC tag programmer and a load of NTAG213 stickers. They work, I've just not had the opportunity to use any yet because the printer broke! I tested the tags just by holding them next to the spool holder and the printer seems tricked into thinking there's a spool of my choosing there.

Progress!

The 6-pin stepper cable was never removed or touched, but I checked it anyway - no issue there. There's also a 4-pin connector of the same type going to a small board that I had unplugged and reinserted - again no issue there.

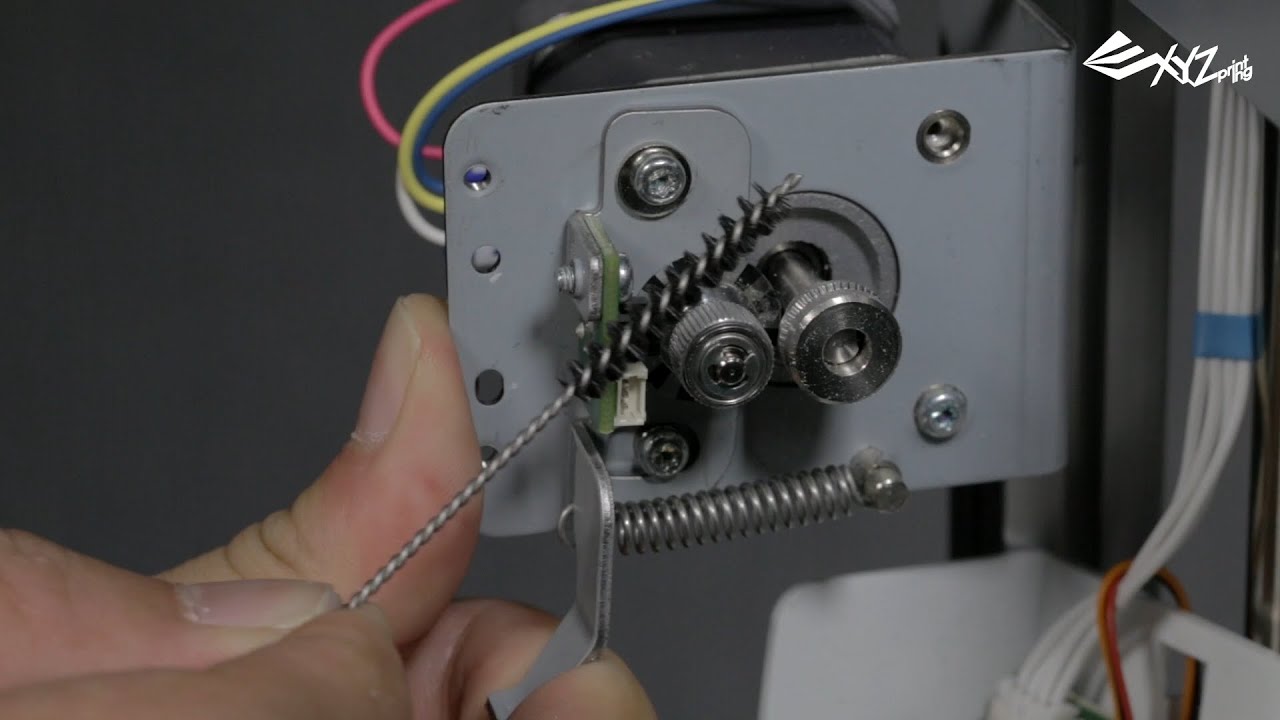

I checked the pinch rollers - they're perfectly aligned. The filament is sitting absolutely dead centre on both the channel in the drive roller, and the grooved part of the other roller. I can't see any way to adjust spring tension. It's quite high, because it takes a bit of effort to pull it far enough to insert filament, so it's not that easy to get the filament all the way down the bowden to the extruder for loading. This is no different from how it has always been.

The thing that made the biggest difference is changing the filament. I was using the 100m roll of white that came with the printer, and was down to the last 15m. I'm now using a new roll of "XYZ Junior series 600g clear yellow". I've got thump thump thump from the feeder when it first starts putting down the raft or first layers, but the raft looks fine. That stops after about 2 layers, and it seems to act normal with the setting tweaks below. It is now printing "ok" but I'm sure it was better originally, so there must still be things to resolve. I don't think the thumping is the offset, because it does it even with the nozzle 2mm above the bed. Could there be something in the main body of the extruder that isn't right?

So far the best results I've got are by slowing down everything. Print speed to "low", reducing the retraction speed to 20mm/s, reducing the retraction distance to 3mm, and bumping up the temperature by 5C (it monitors at 206C).

It seems to have a lot of trouble getting that first layer down, and I'm going back to trying different Z-Offset settings to see if that can be resolved. At the moment my nozzle is 0.25mm from the bed at the edges, and about 0.20mm in the middle - I don't know why the bed is raised in the middle - I'm thinking of flipping the glass over and see what happens.

I printed off the official "wind duct" that attaches to the extruder - it printed ok, even though I had the thump-thump at the start. I can't say that's making any difference at the moment, but I've left it attached for now.

I printed the samples - the little heart pendant and the twisted vase - both seem ok, and look the same as the ones we printed when we first got the printer. Neither are brilliant, but they're reasonable. Again, first two or three layers "thump-thump-thump" then normal. Again I needed to adjust the speeds and temp.

If I printed the E3D hot end mod, does that mean I could have a 0.3mm hot end, or would I need to buy the "XYZ 0.3mm extruder with nozzle" first? If I'm going to have to replace it, I'd rather have the higher resolution.

I'm a total newcomer to 3D printing, based in the UK, and have a DaVinci Junior 1.0

My background is programming, web design, and vinyl cutting!