Some (good) news !

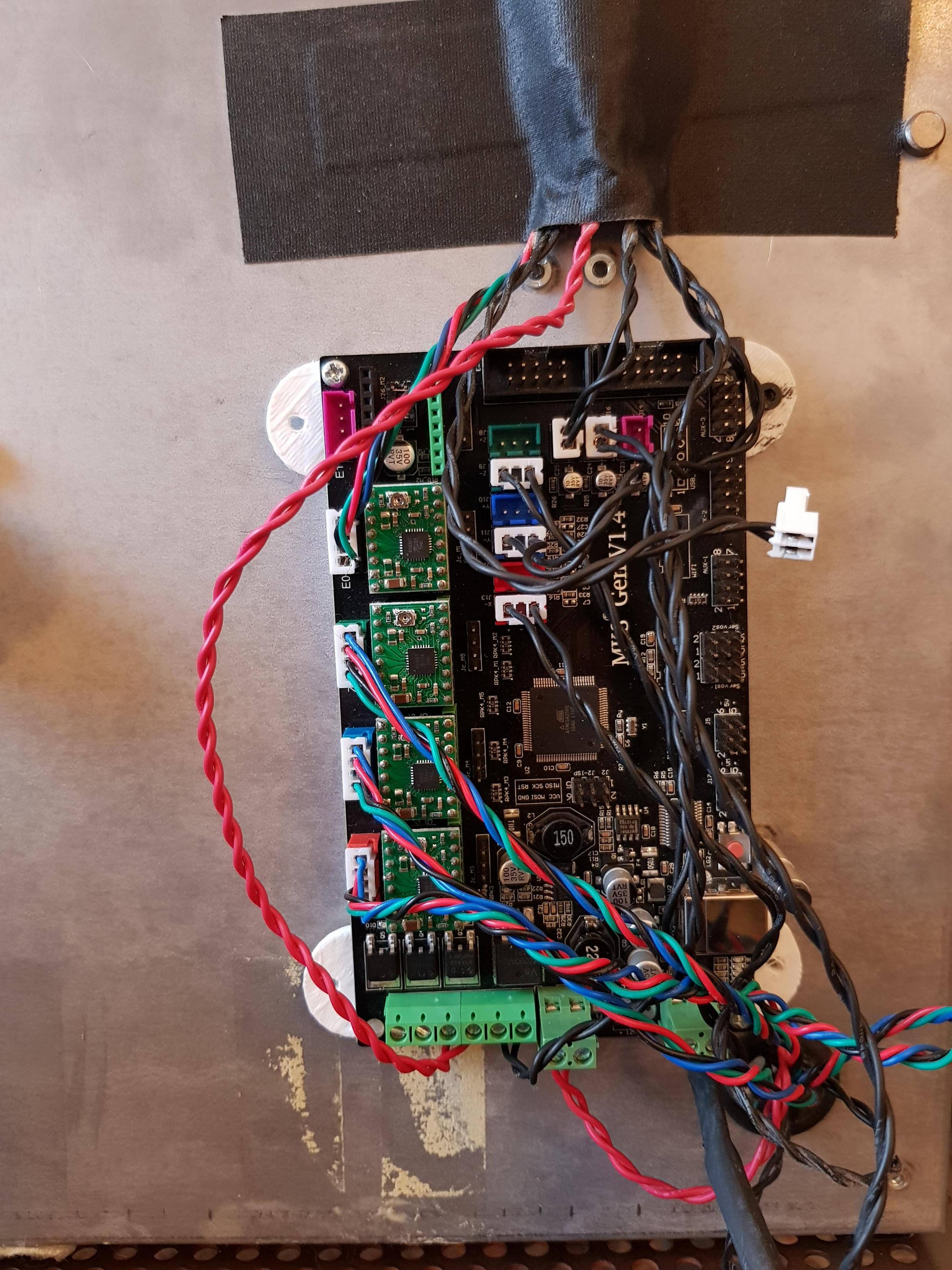

I have finished to attach the board to the printer and started some testing.

To resume, what were the important points I went through :

0. I used the https://github.com/ozadr1an/Solidoodle- … in_v1_beta firmware. Not sure that was the best choice

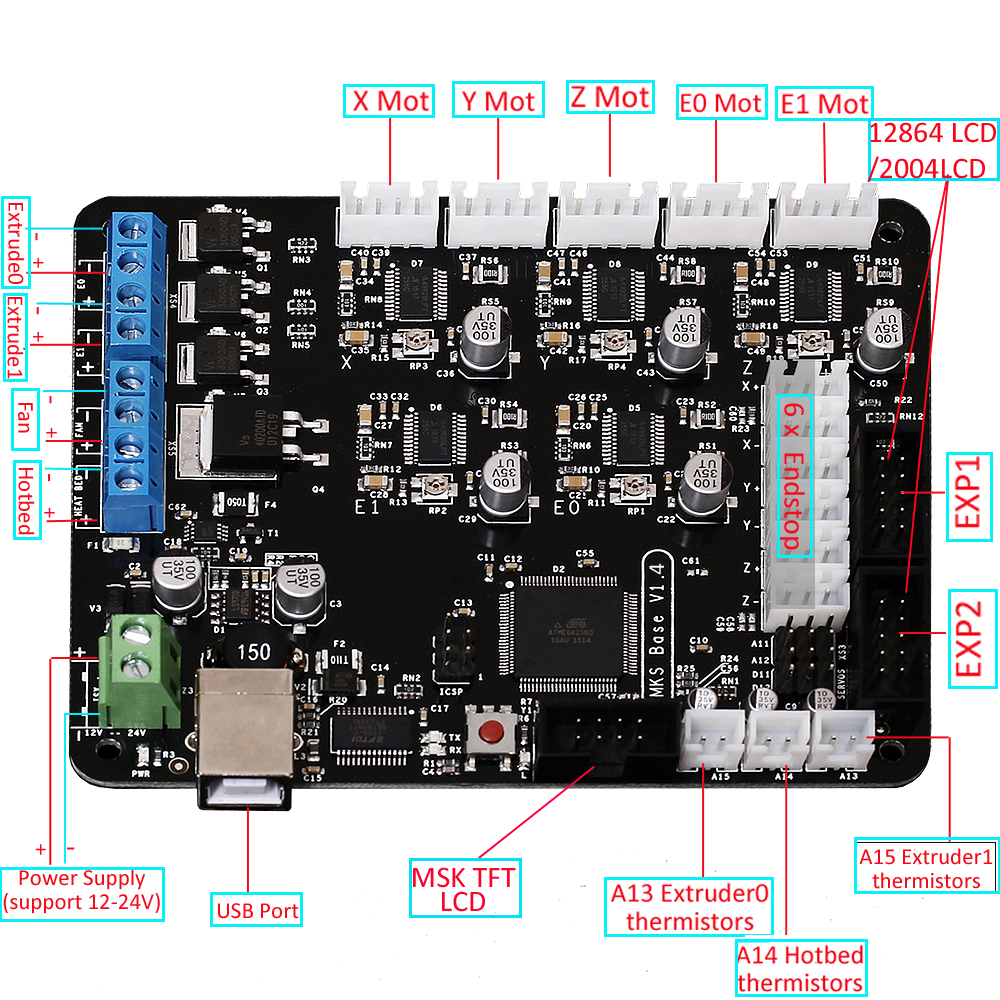

1. Buy some XH-4P, XH-3P and HX-2P female connectors to be able to plug things correctly on the board

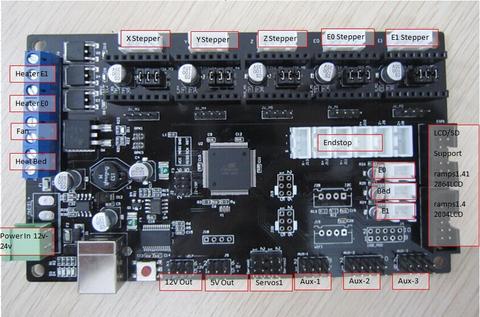

2. endstops are plugged differently on the sanguilolu (GND/5V/PIN) and the MKS gen 1.4 (5V/GND/PIN). It has to be plugged GND/PIN

3. X and Y endstops have to be on the max not on the min. Bypass the other endstops. They probably can be desactivated through the firmware but as I am not sure if there are not some side effect, at least it works like this.

4. On the firmware side :

4.a. on Configuration.h I changed :

#define MOTHERBOARD 33

#define SOLIDOODLE_VERSION 2

#define INVERT_E0_DIR true

The extruder stepper was going the wrong way as the X and Y stepper. I did not change the X and Y direction because it seems to create other problem with the rest of the firmaware behavior.

4.b. on the pins.h I changed line 601

#define HEATER_0_PIN 10 // EXTRUDER 1

There is a strange coding here on this version of the firmware between line 598 et 602 ...

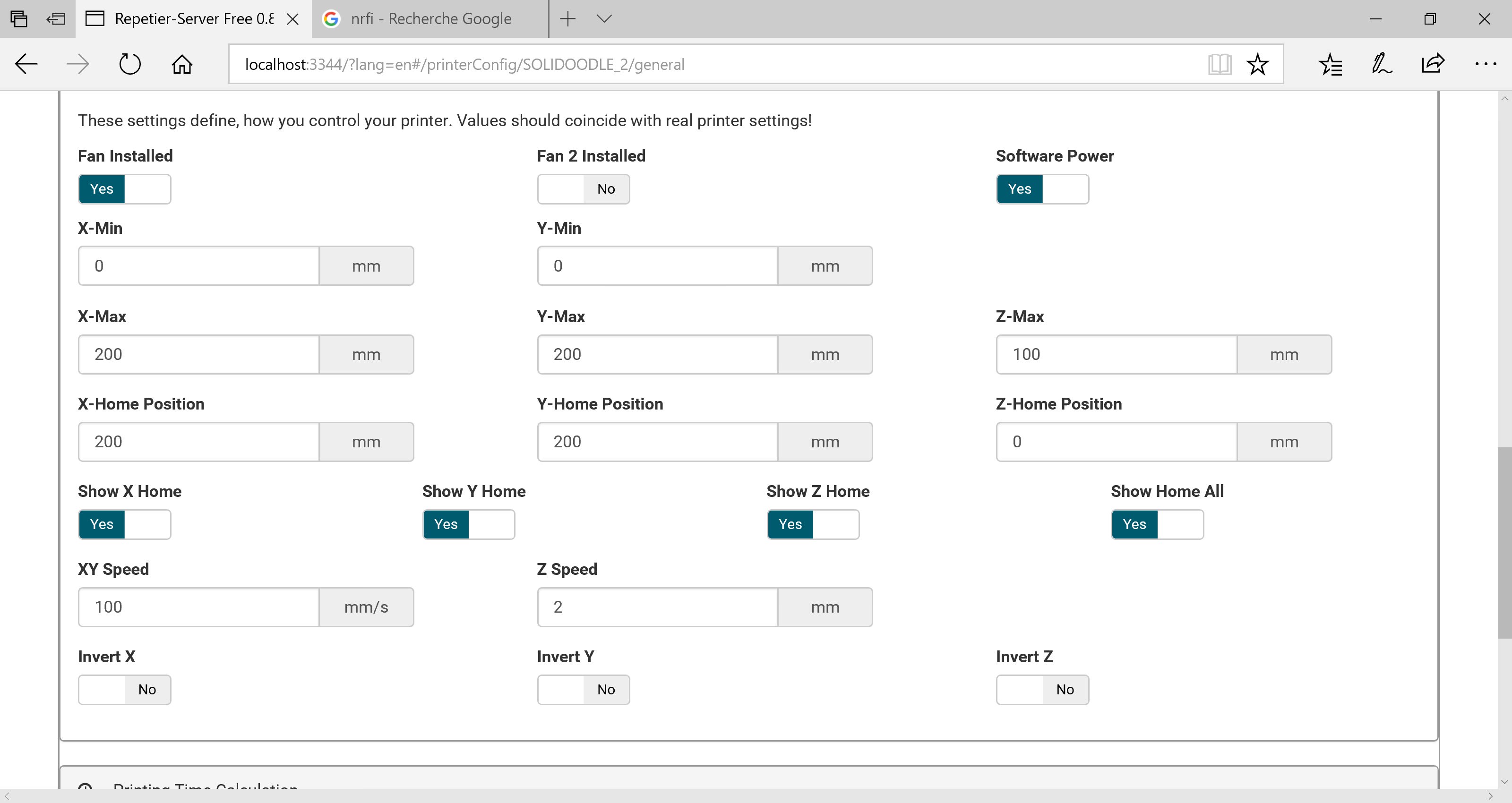

5. on the cufiguration in reperter I have put X home at 155, Y home at 150

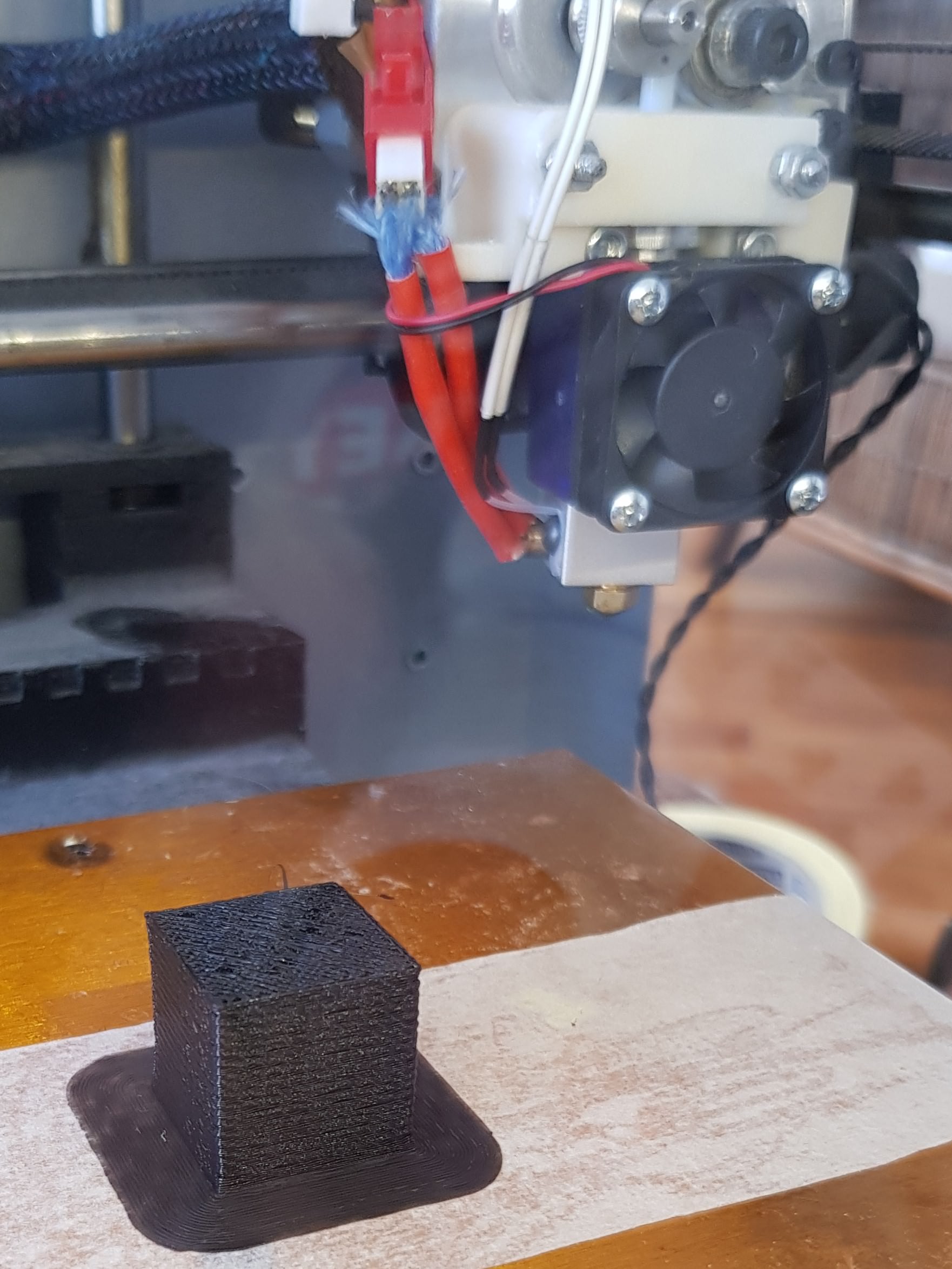

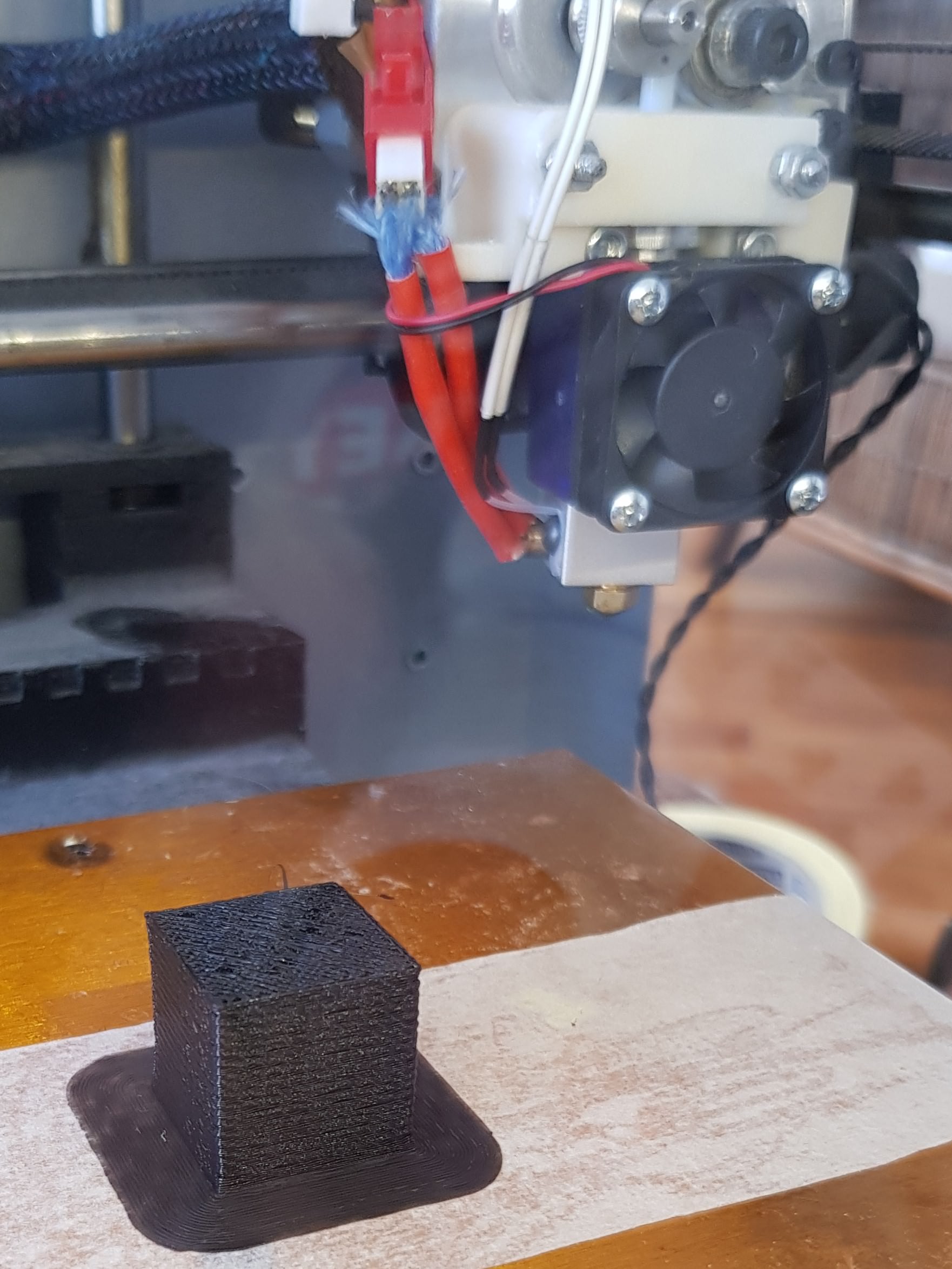

I did some testing with PLA slicing with Cura and printing with repeiter. It is far from being perfect I need to do some fine tuning. I probably will need some help with the basic configuration for PLA. I have tried different things for adherence, the only one that worked until now is the masking tape ...