Topic: SD3 flexion head - anyone done it?

Hi all,

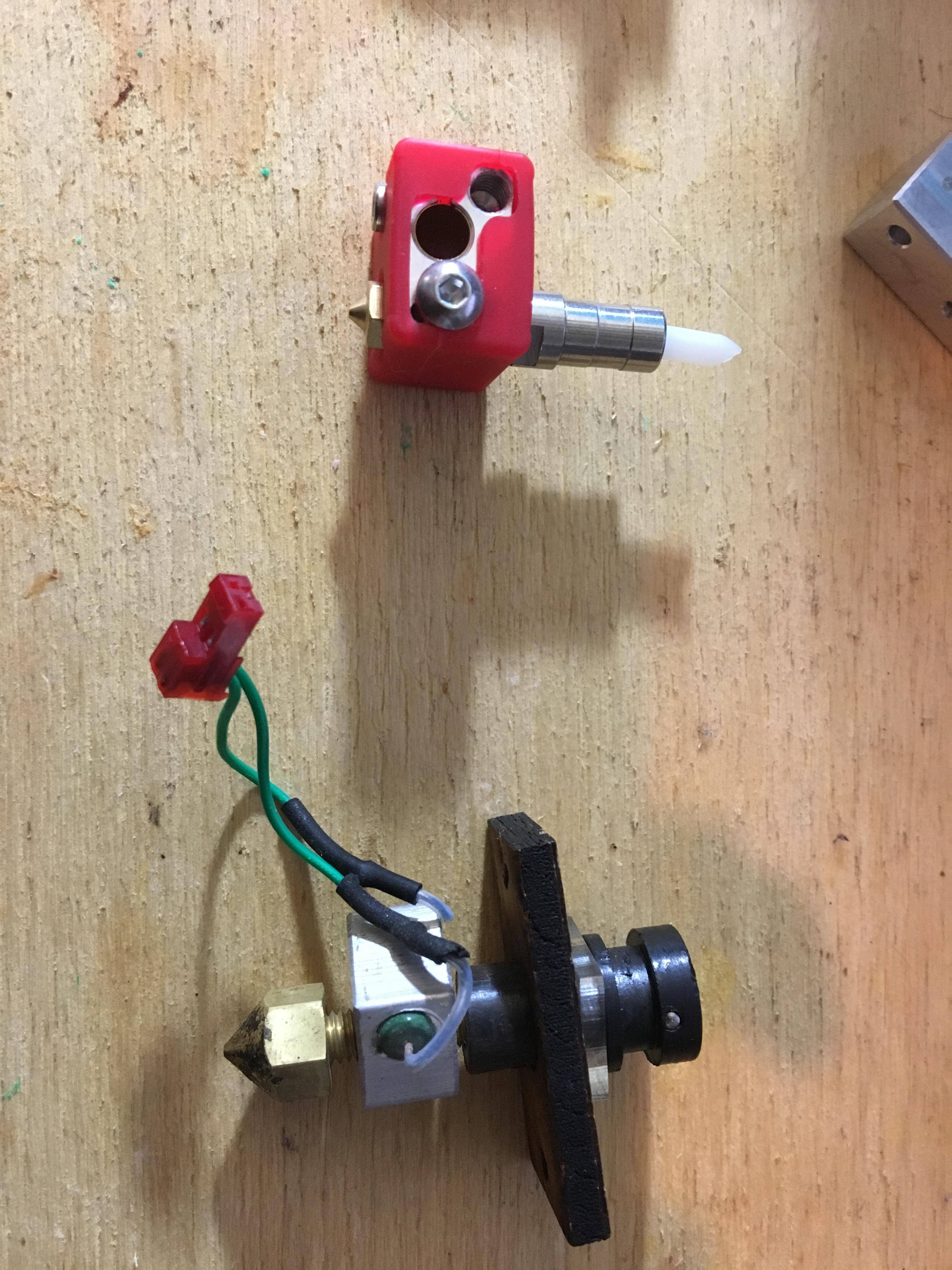

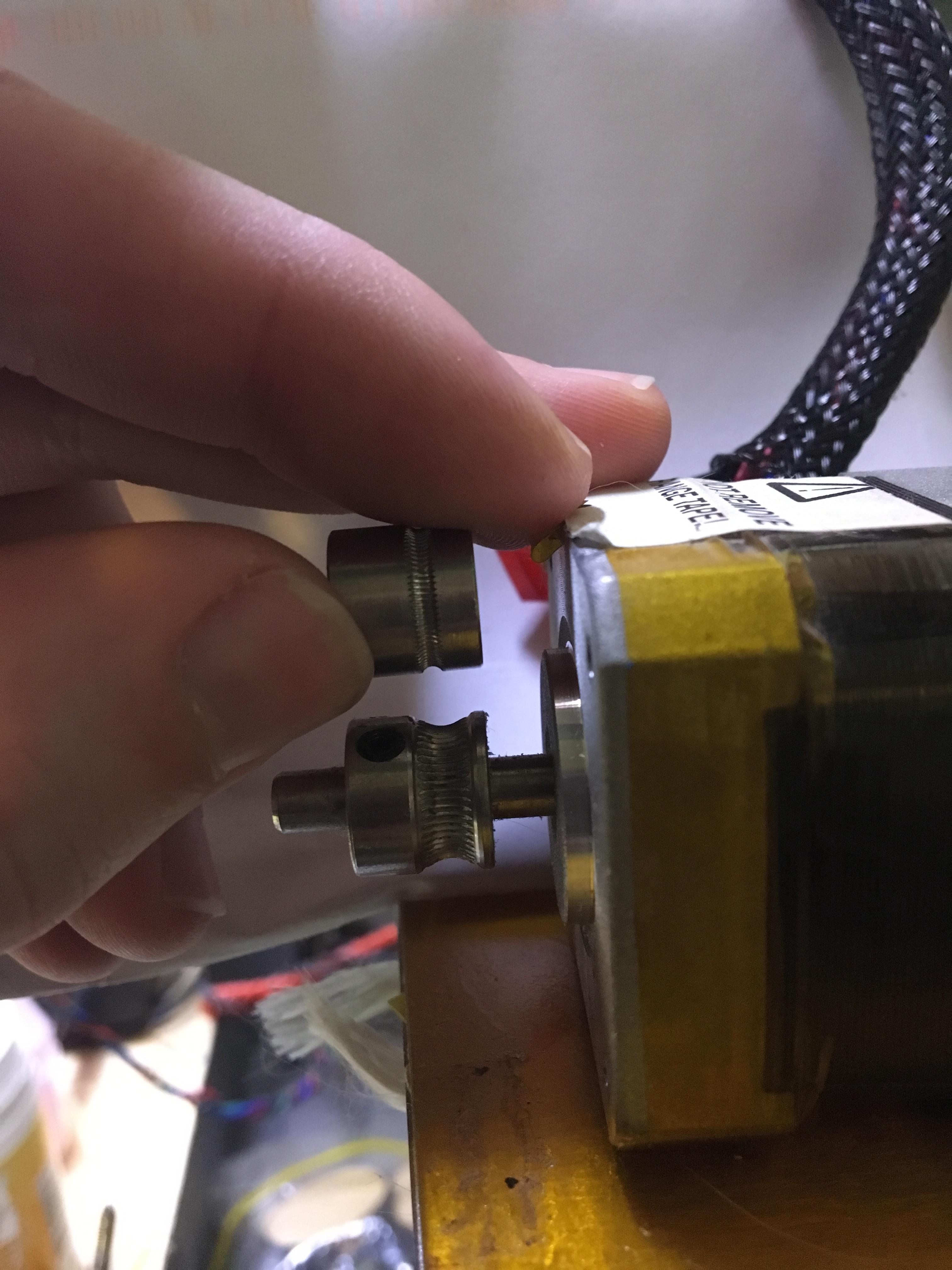

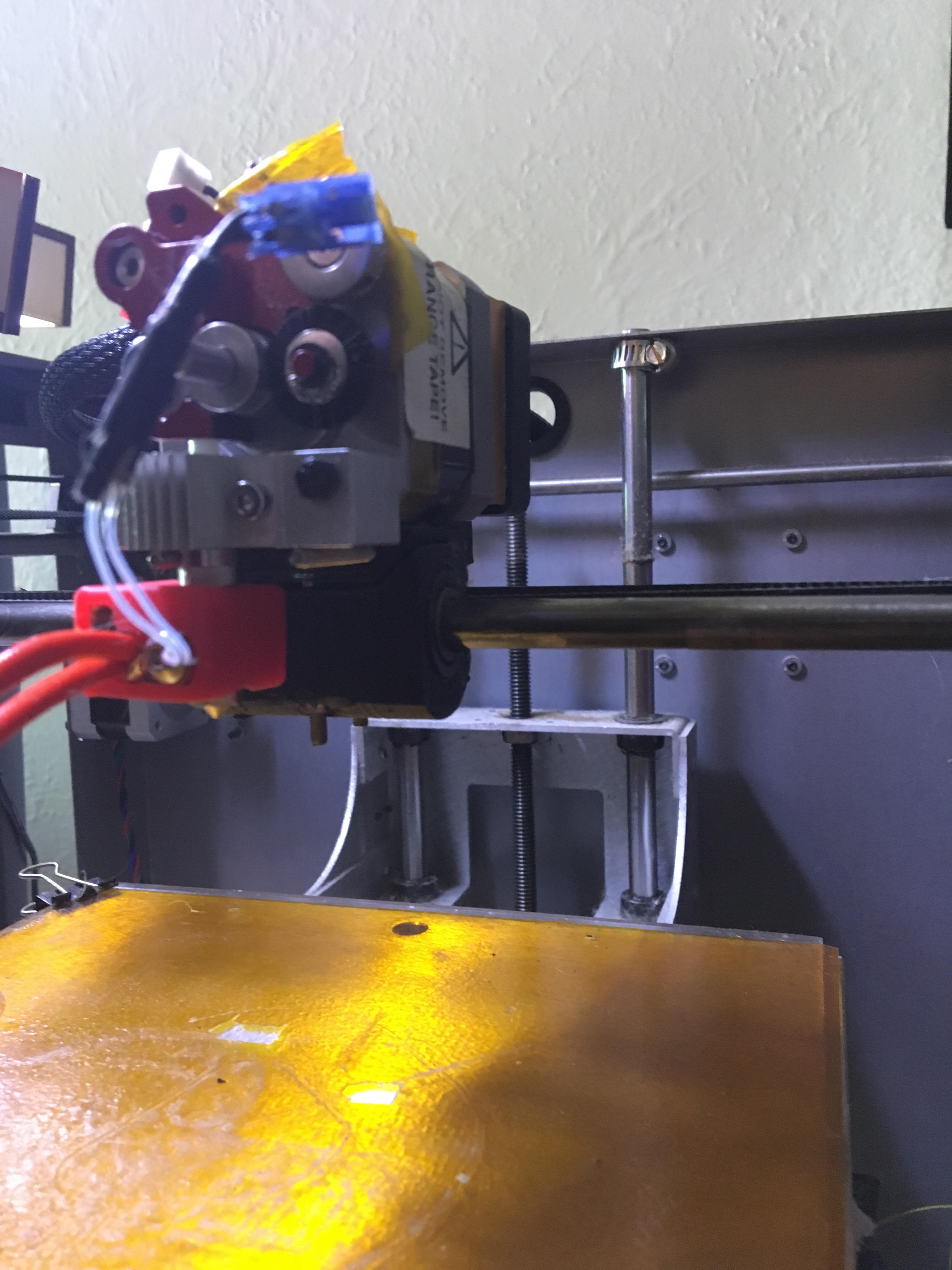

seems I cant get the old SD3 to print TPU very well. So i bought a flexion extruder.

So after talking to Flexion, they suggested I buy their standard head (not the E3D head).

Has anyone fitted one of these to a Solidoodle (or similar) before? any tips or pics? Searching here and google is giving me a lot of noise, no real clear answers.

Cheers,

Tommy