Topic: [ABS] - Polylac PA-747

(Sorry this was delayed; we had a broken ac and a defrosting mini-fridge to deal with yesterday evening.)

Since I am going to start a batch of colored filament as soon as the weekend begins, I figured that I may as well document my last run of natural for the week.

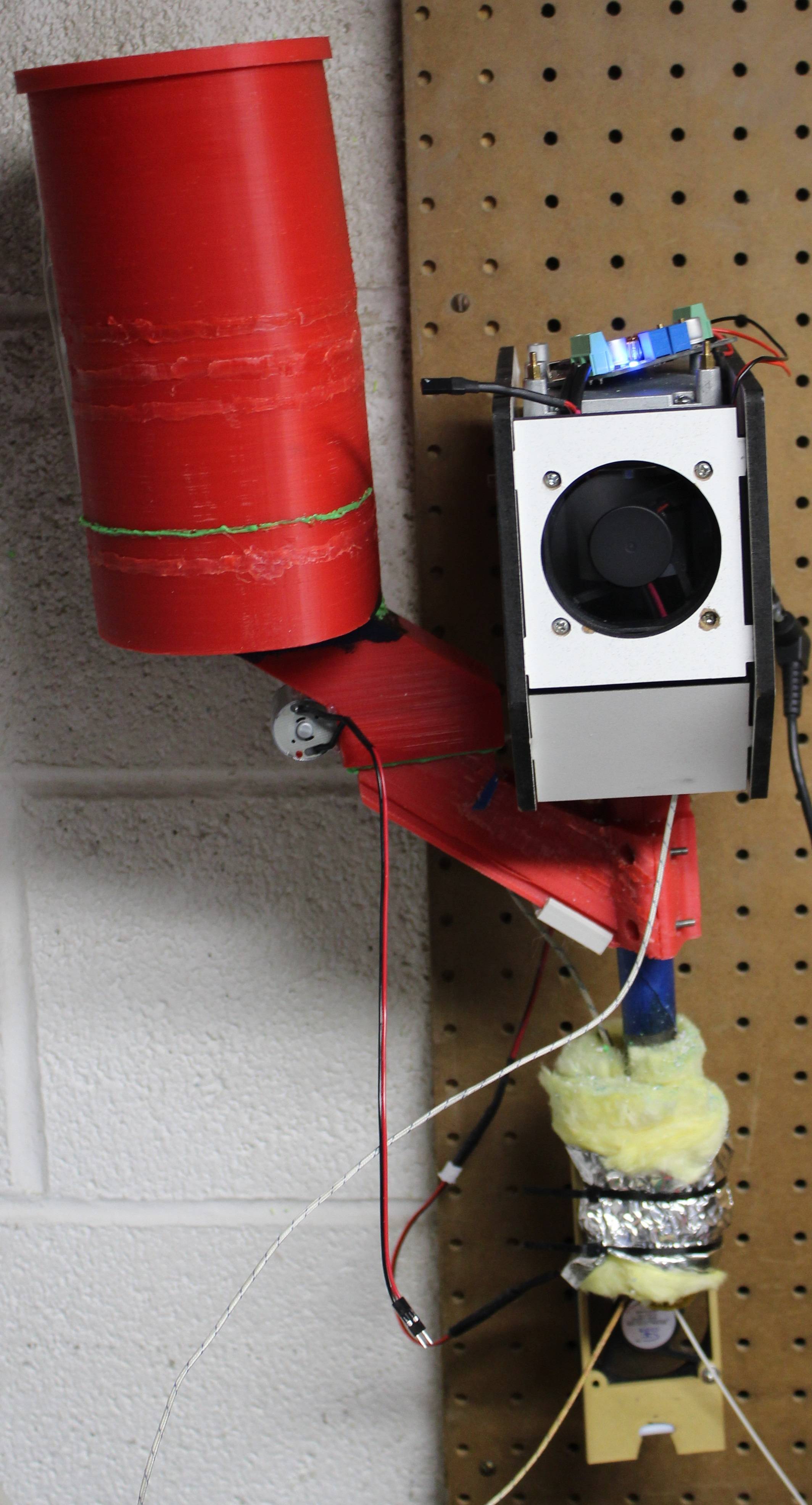

So, here's the machine, a Filastruder 2.0:

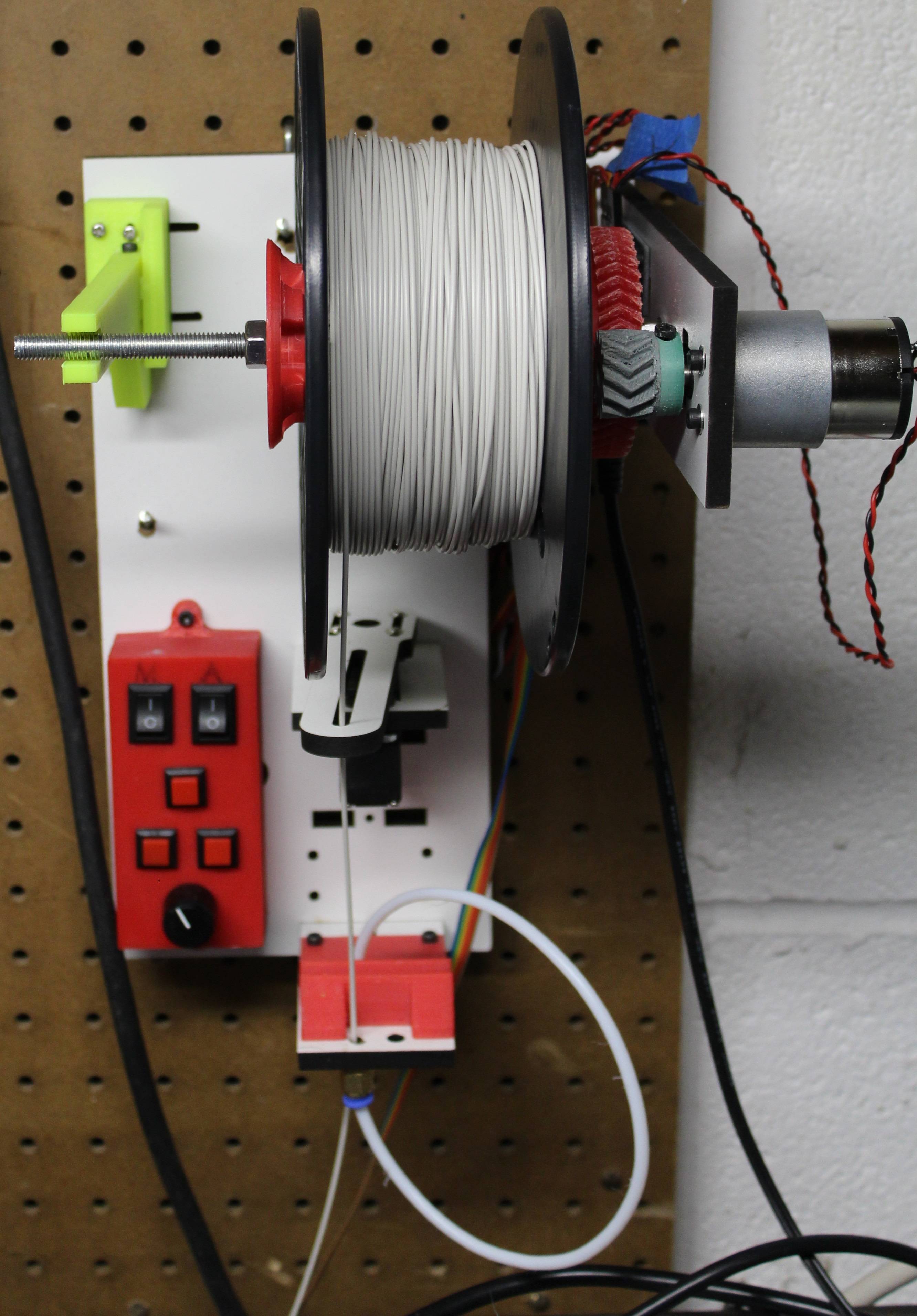

...and its Filawinder:

The nozzle is the stock 1.6mm drilled, with filter.

The diameter is 1.64mm +/-0.01mm. The only exception to this is the start of the spool (obviously).

I got 20lb of the pellets on eBay from themadwand. He/she is actually selling them again. Here are the remaining pellets, in a trash bag, in the shipping box:

A closer look:

Before I do anything with the pellets, I always dry them in my dehydrator:

Once that's done, the pellets end up in one of two places--either the paint can that I use to mix pellets with colorants, which I store a kilogram of pellets in at a time, or into the overflow bag, from which I pull natural pellets to make natural filament (It's the bag in the close-up image of the pellets).

When it's time to actually do a run, I turn on the Filastruder's heater, dump the pellets into the hopper, and prep the Filawinder for incoming filament. If there is still time, I might also put the pound bag of desiccant in the microwave to recharge it (5mins, power-level 3). When I get a chance to pull it out, I end up playing hot potato with it as it releases hot moisture. To finish this process, I simply leave it on the output vent of the nearby dehumidifier, where the driest air in the room can wick up any remaining moisture.

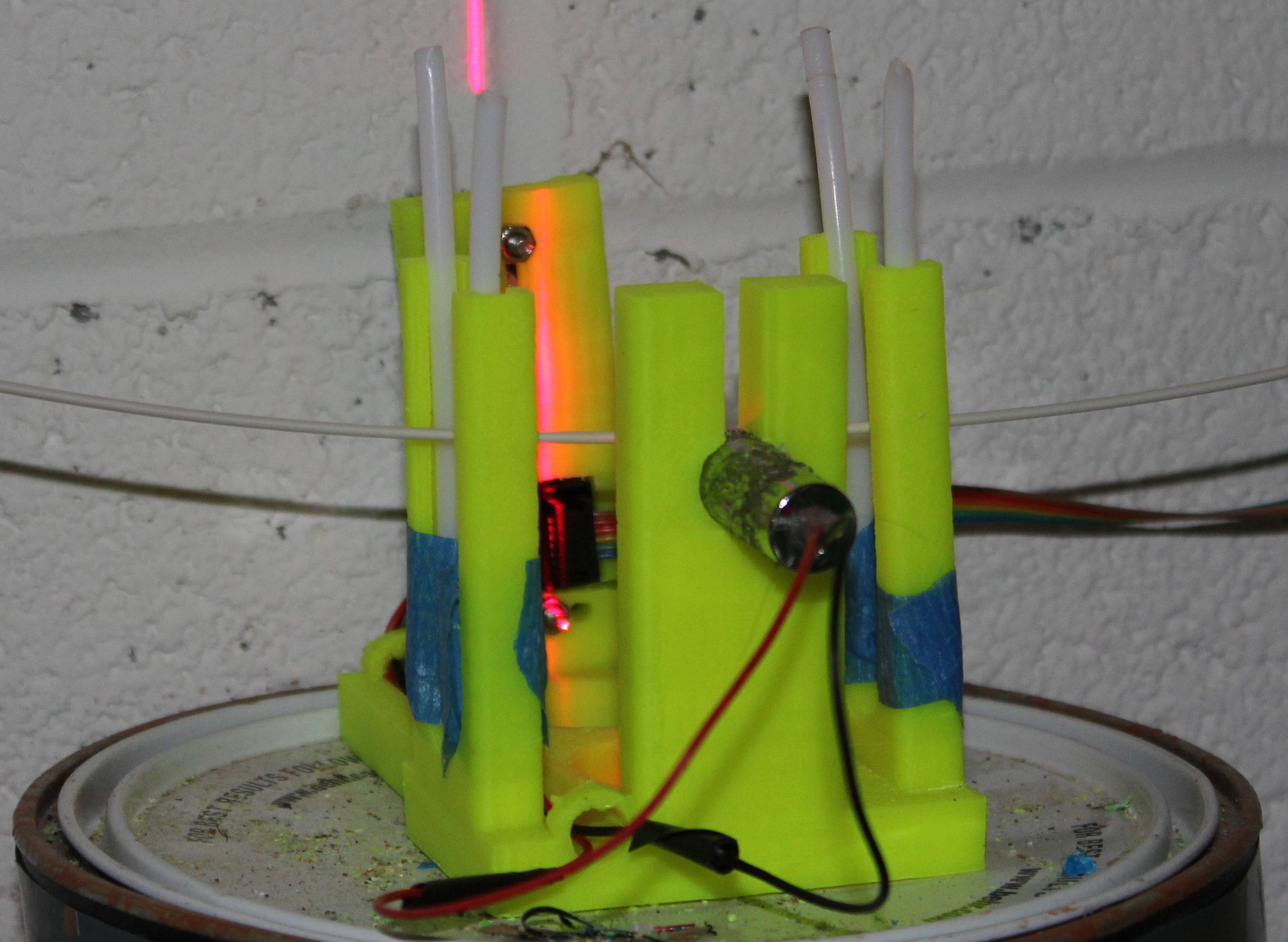

Back to the Filastruder. As soon as the first foot of filament has been extruded, I pluck it from the nozzle and dispose of it. The rest is fair game for spooling...as soon as I get a strand to the Filawinder. The pegboard offers convenient "pivot points" for the end of the filament while I wait for the strand to get longer, but I don't believe I have gotten a strand across in the first try. (good thing I have a printer pen!)

Once the spooling begins, I simply check on it every now and then to make sure the arm positions are correct, the pellets are feeding okay, the spool's holding nut is still tight, etc.

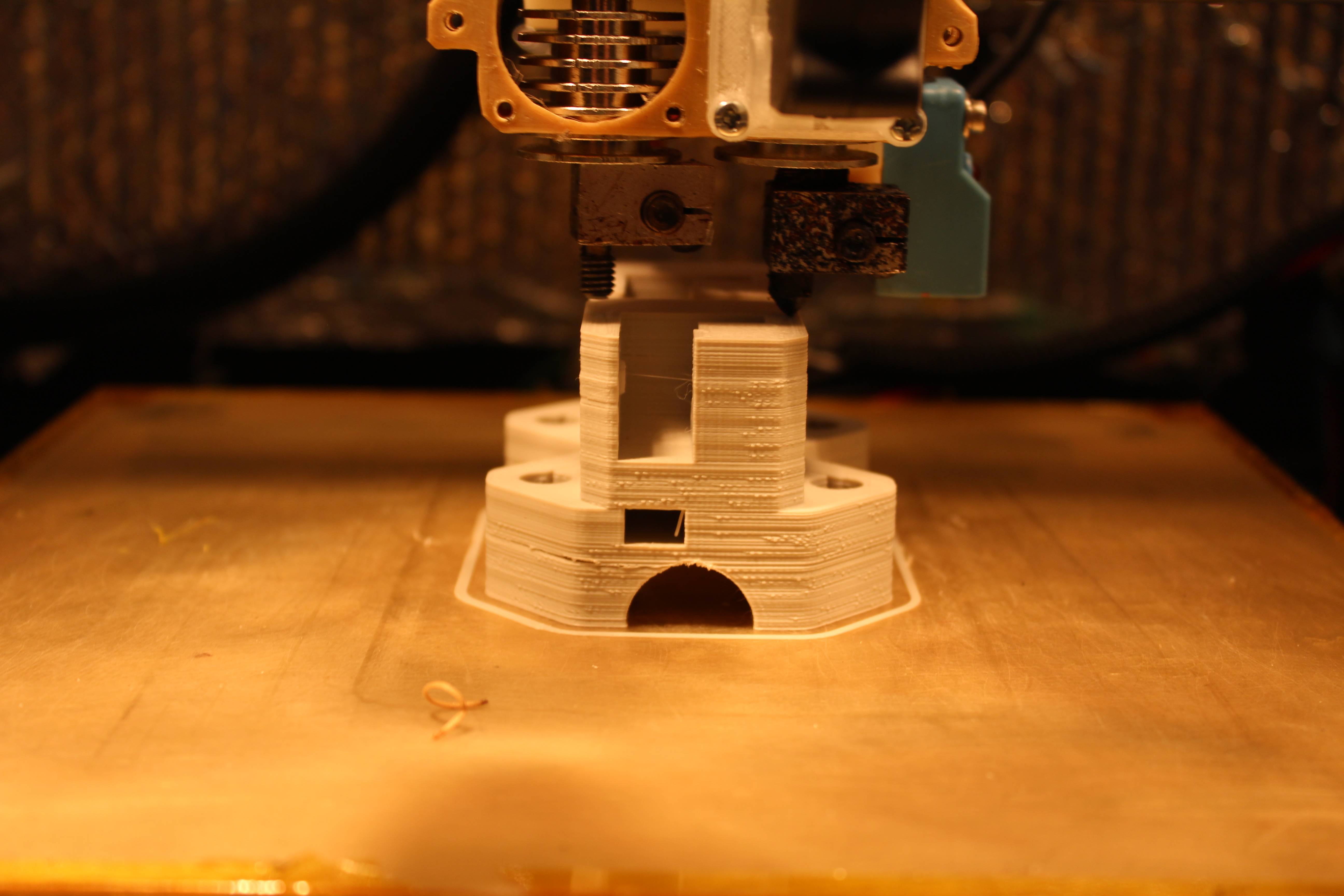

A part being printed with the filament:

...which reminds me: this natural PA-747 filament has had better overhang performance in my machine than commercial filaments. I'm not entirely sure if it's the colorant, the formulation, the diameter, or something else.

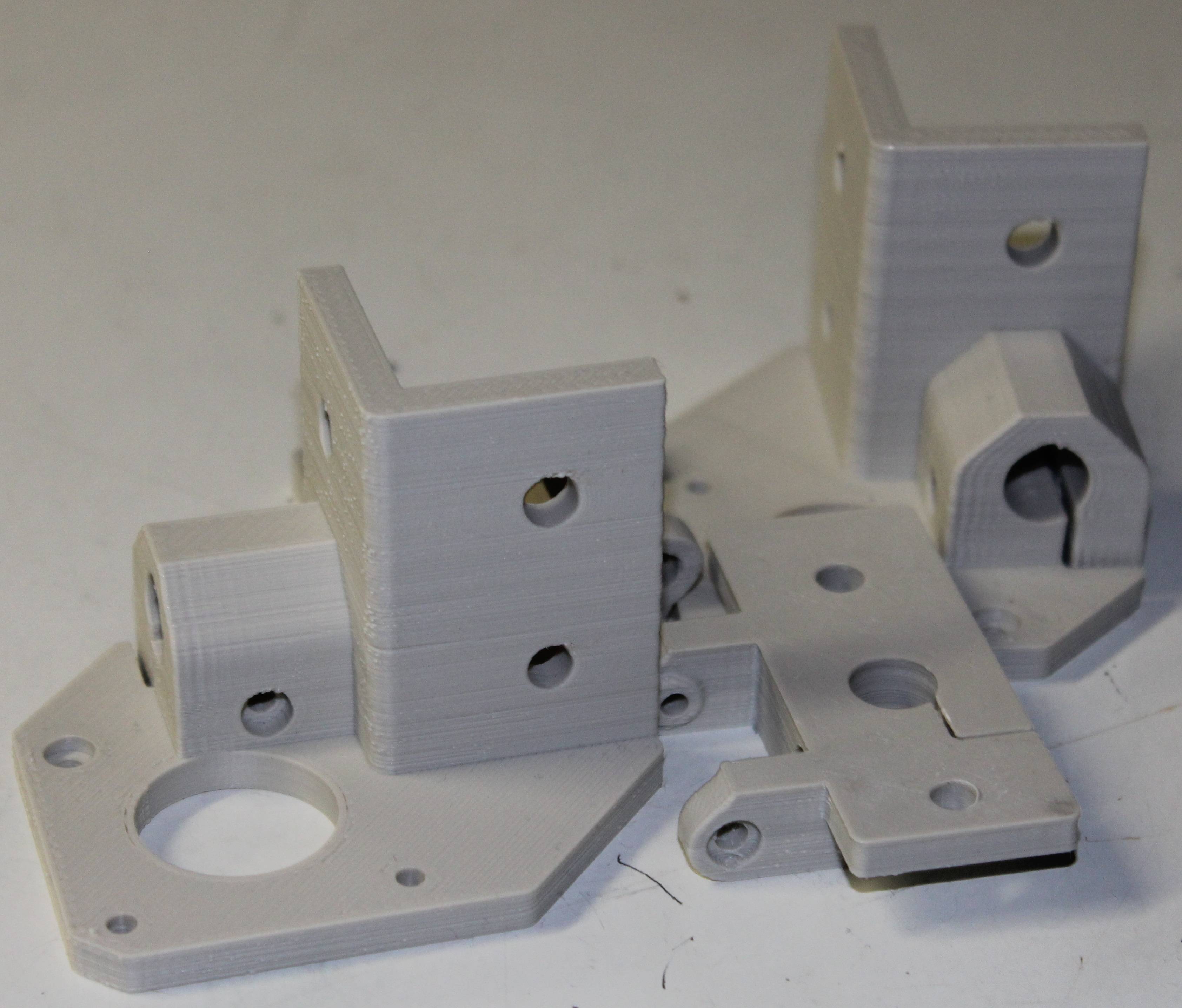

Some HyperCube Evolution parts:

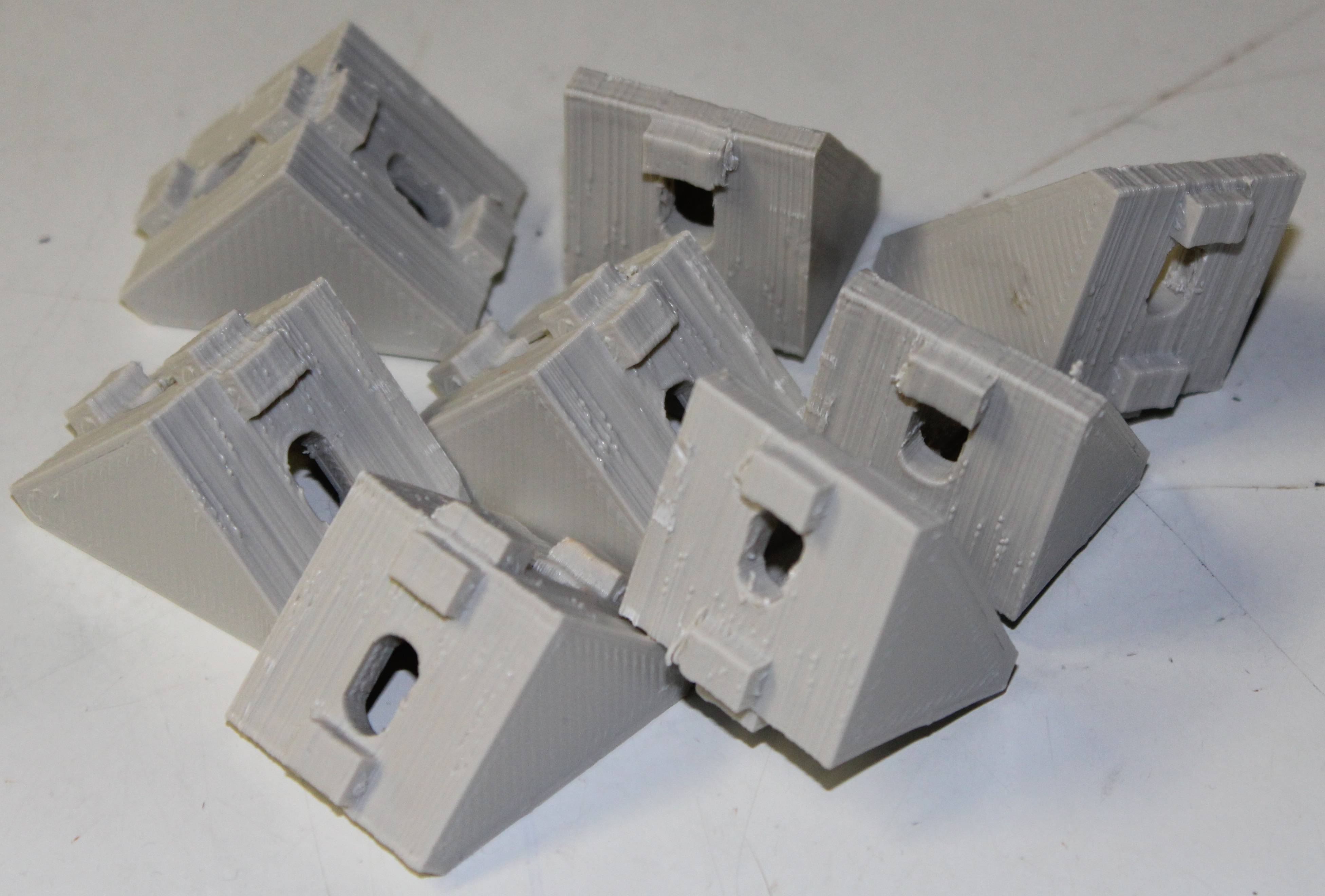

Some 3030 corner brackets:

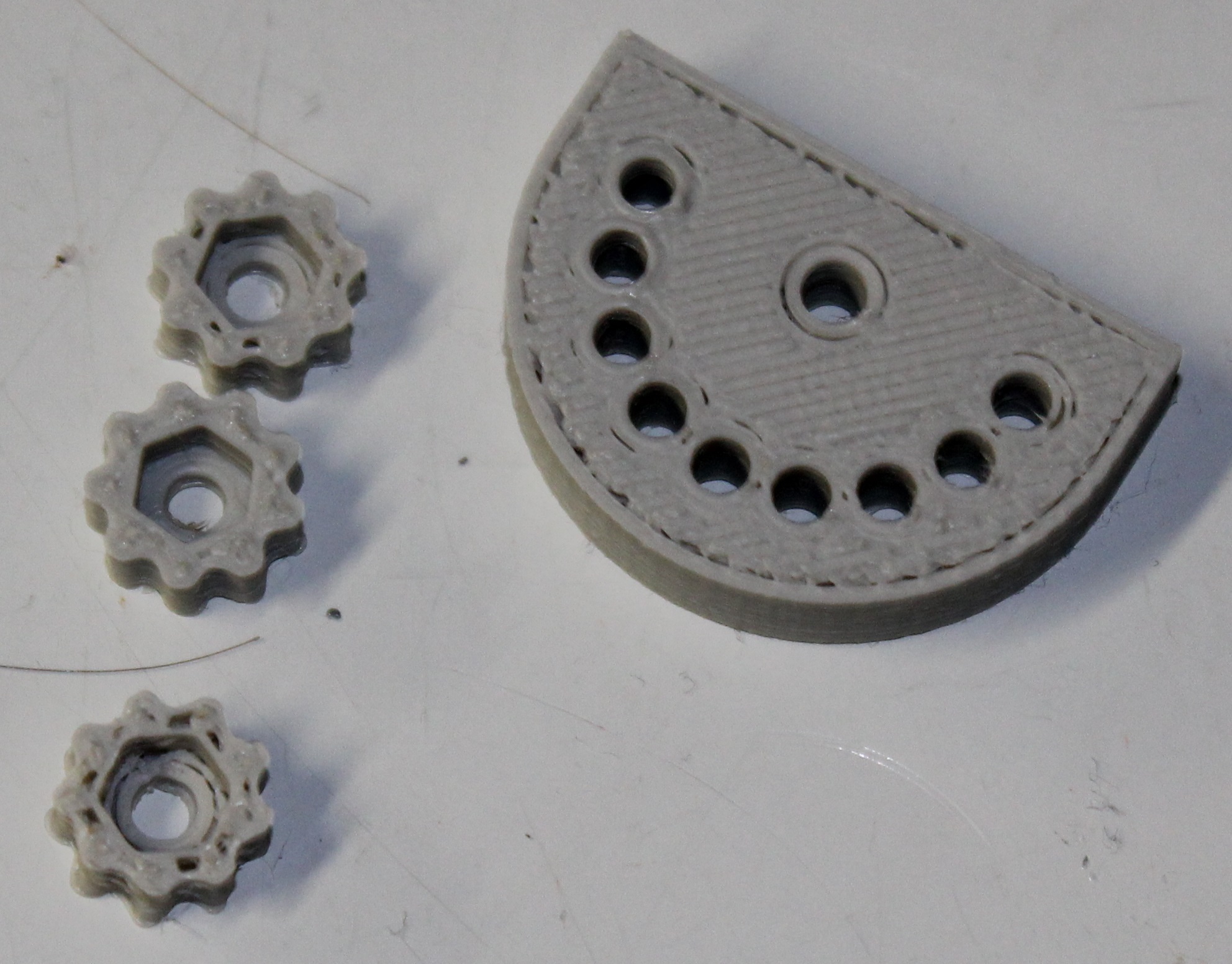

My own parametric hyperbolic worm gear (Woah, that's huge! The actual part is only 4cm long)

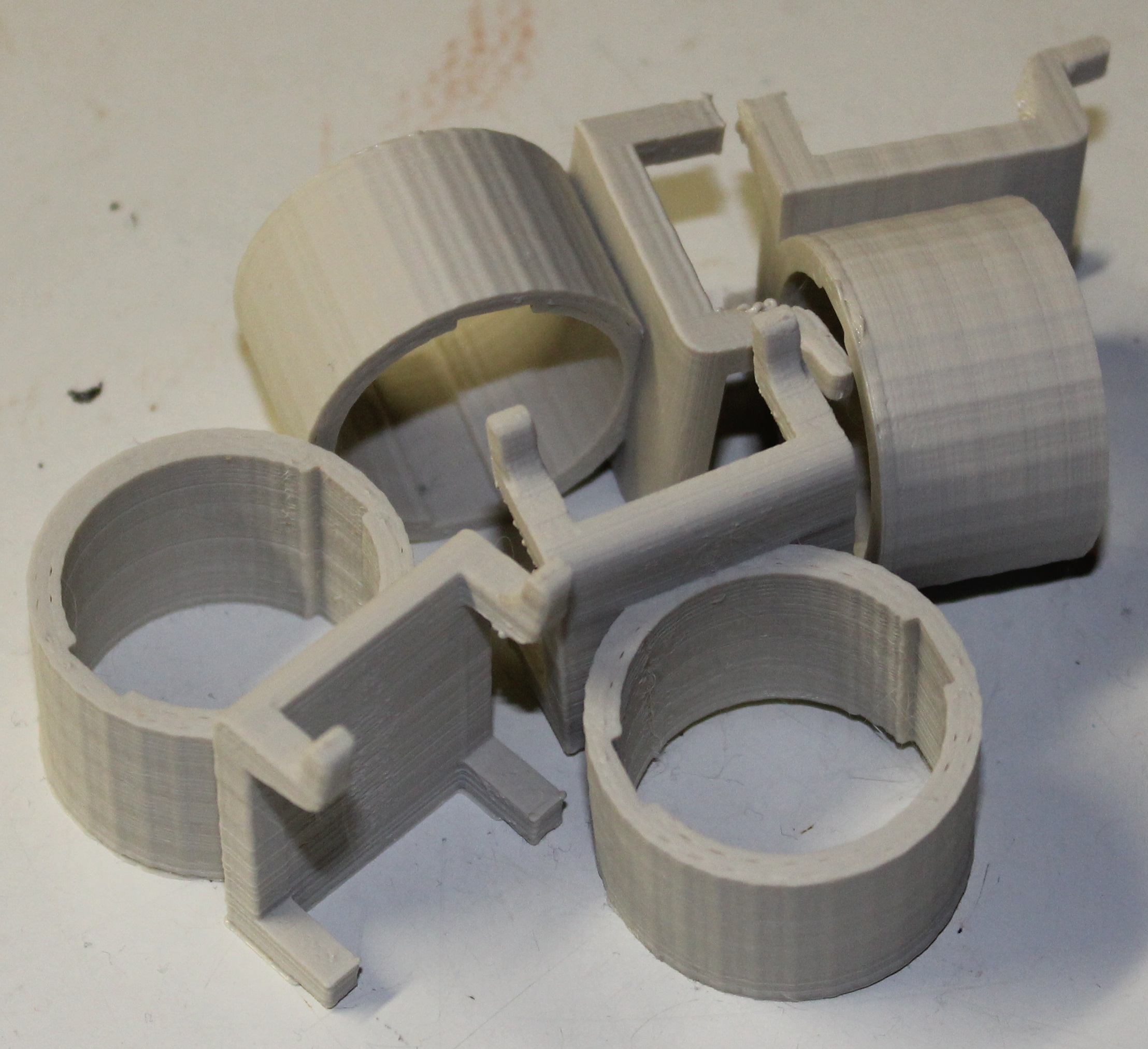

Some smaller parts of a Dremel Table Saw:

Parts of a Dremel Micro-Lathe:

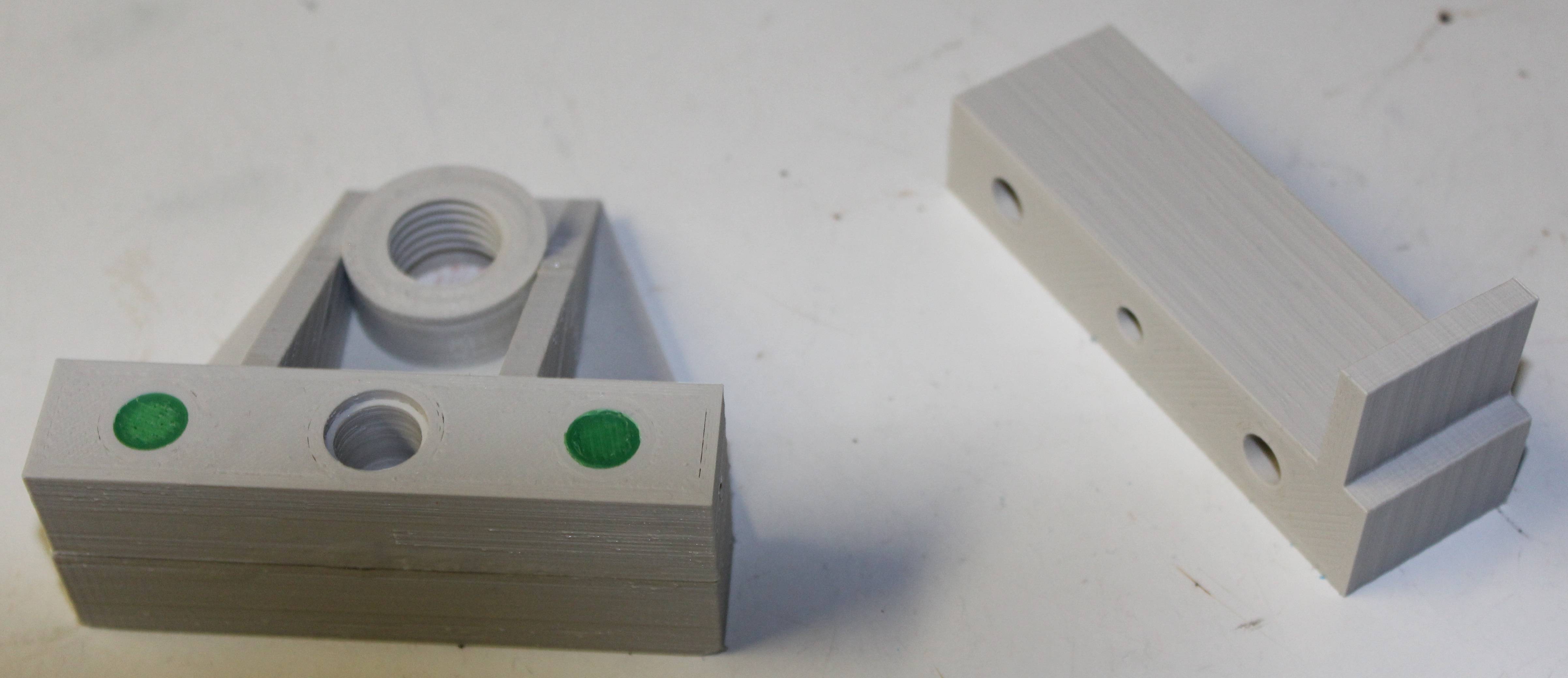

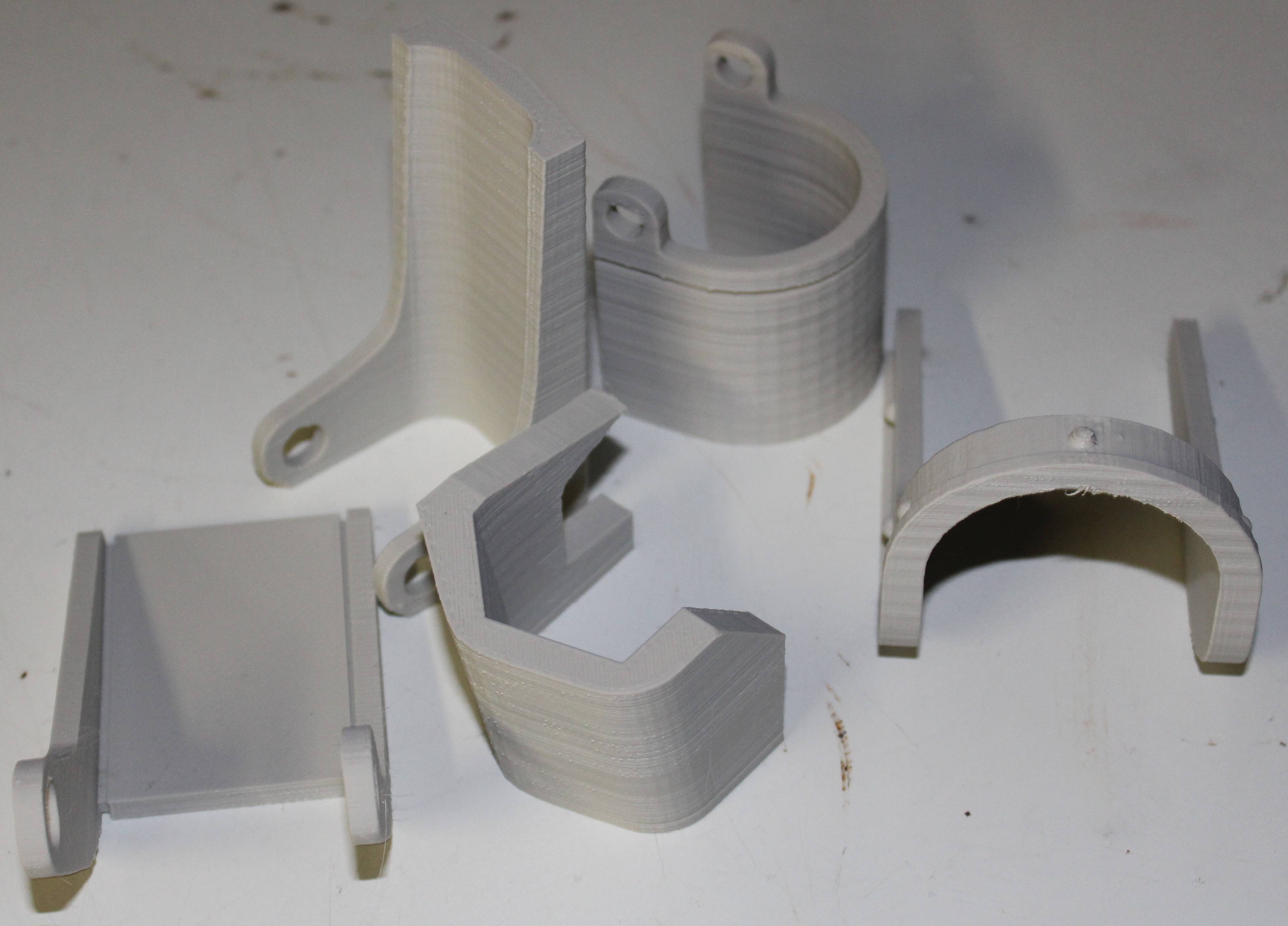

Some pegboard Harbor Freight chisel holders:

And some of the larger parts of jarviswoo's Iron Man MK1 figure:

I'm quite happy with this stuff. It's cheap, paintable, and just satisfies me that, after all the troubles I've inflicted upon myself, I finally have reliable homemade filament.

Dual-extruder MaxMicron Prusa Mendel: RAMPS 1.4 w/ Repetier Firmware+Full Graphic LCD Controller, stock hotends, 3Dator extruders w/ MK8 gears, insulated enclosure w/ 2 heat lamps, RPi 2B w/ Repetier Server.

0.1-0.2mm layer height, heated bed w/ PEI surface, inductive-sensor autolevel, 0.5mm to 0.2mm nozzle diameters.