Topic: Solidoodle 4 - to up grade or not to upgrade

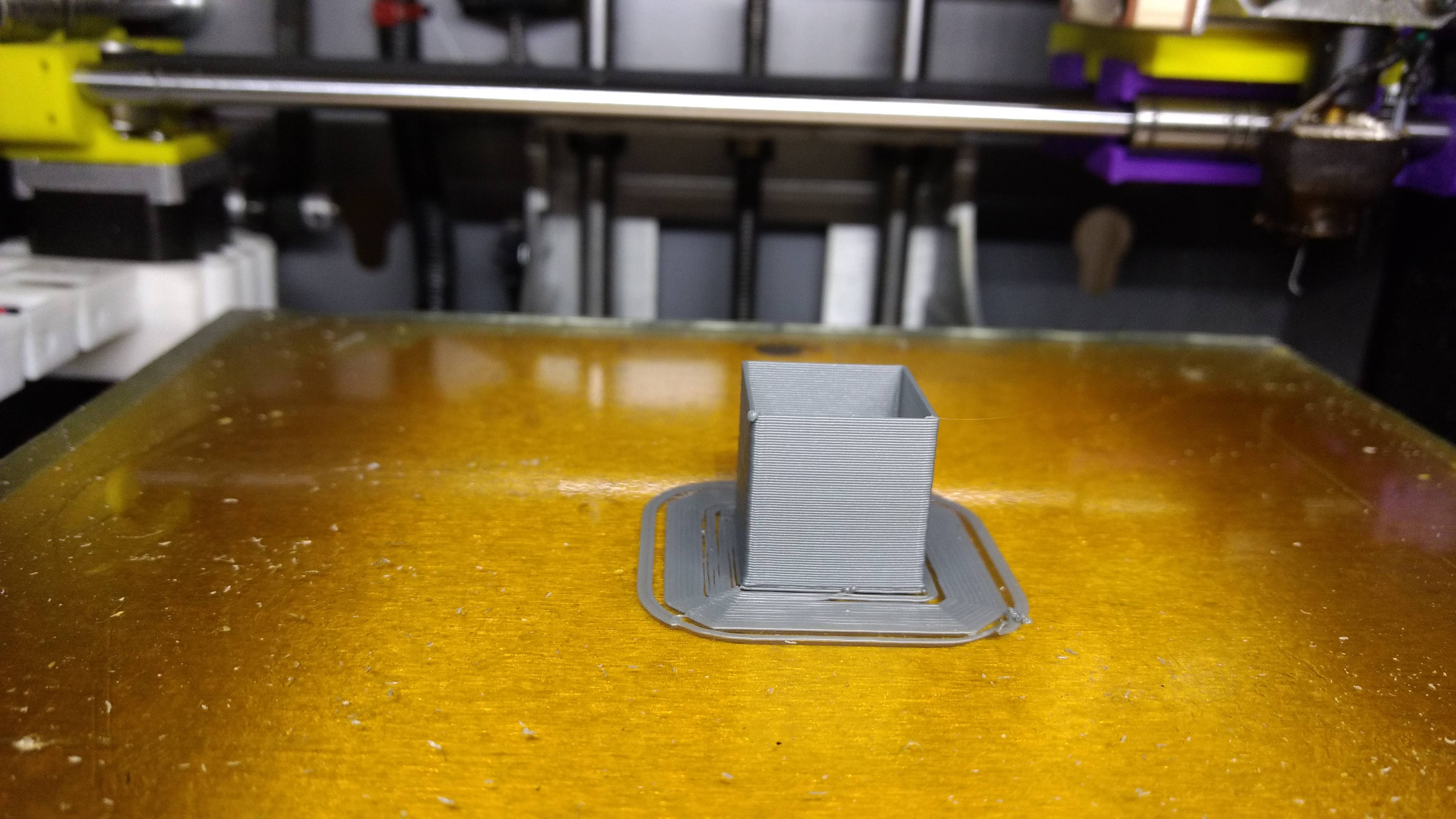

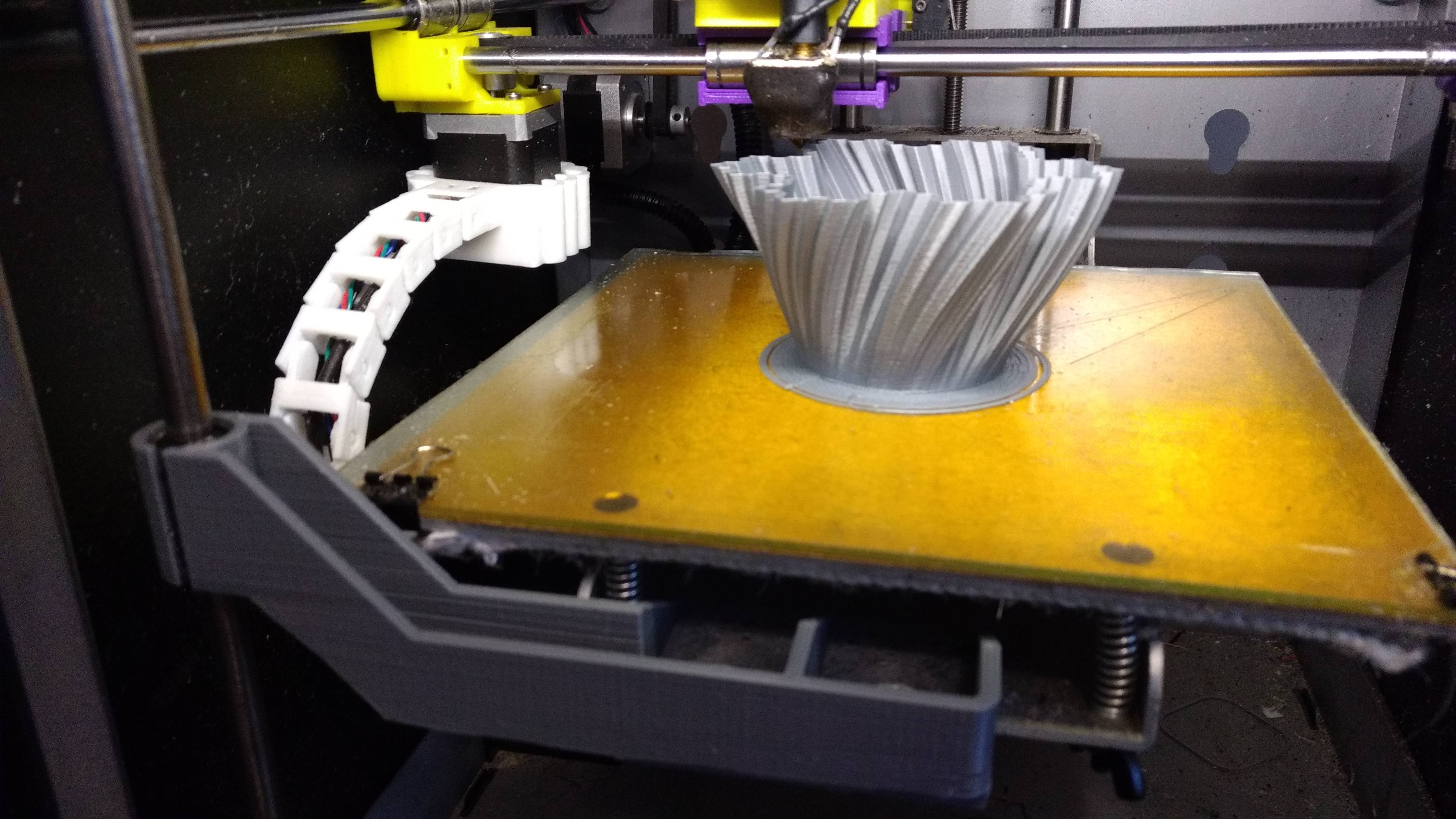

So I've had a Solidoodle 4 for a little over 3 years... it has worked OK I guess, but it is a very finicky beast. I understand 3-D printing is more an art than a science, but this thing is kind of a PITA. I've designed and printed some pretty useful things, but over all I've probably thrown more plastic (PLA and ABS) in the trash than I've actually kept, because of bad prints. I recently upgraded to Lawsy's carriages and new hardened guide rods, and just built some cable chains and rewired the thing to prevent a lot of problems that were caused by cables dragging over the build plate and WIP. Also put a cooling fan on the X-motor, as it got too hot to touch during builds. The movement seems really good and repeatable, and I'm in the process of designing and building a vertical guide rod to stop the end of the build plate from wobbling so much when the head changes direction.

The biggest problem, which causes the most waste, is feeding filament... more often than not, the filament will stop feeding in the middle of a print, or will feed poorly, and I'll get what looks like a "furry" surface where the filament just doesn't feed consistently. I've cleaned the extruder really well, made sure the feed system works, and when printing, the brim looks beautiful, nice and smooth and consistent feeding, and even the outline of the part where the extruder puts down the perimeter of the part looks great, but the middle of the thing is terrible inconsistent. I've considered that perhaps SlicR isn't doing a good job, but really I can see lots of filament "chips" and dust around the feed mechanism, where it obviously isn't feeding well. I think the next mod I need to do is an E3D hot end and Bowden extruder, as well as a cooling fan for the WIP, but My dilemma is this:

When a new printer of a similar size and apparently much better quality can be had for less than $200 like this Anet A8 https://www.youtube.com/watch?v=IFBWh8tiTZg

...or this Creality CR10 for less than $500 https://www.youtube.com/watch?v=0i-Mv6Td1H4

...is it really worth putting any more money into this Solidoodle?