Topic: Solidoodle 2 pro with e3d v6 head blockage

Hello all,

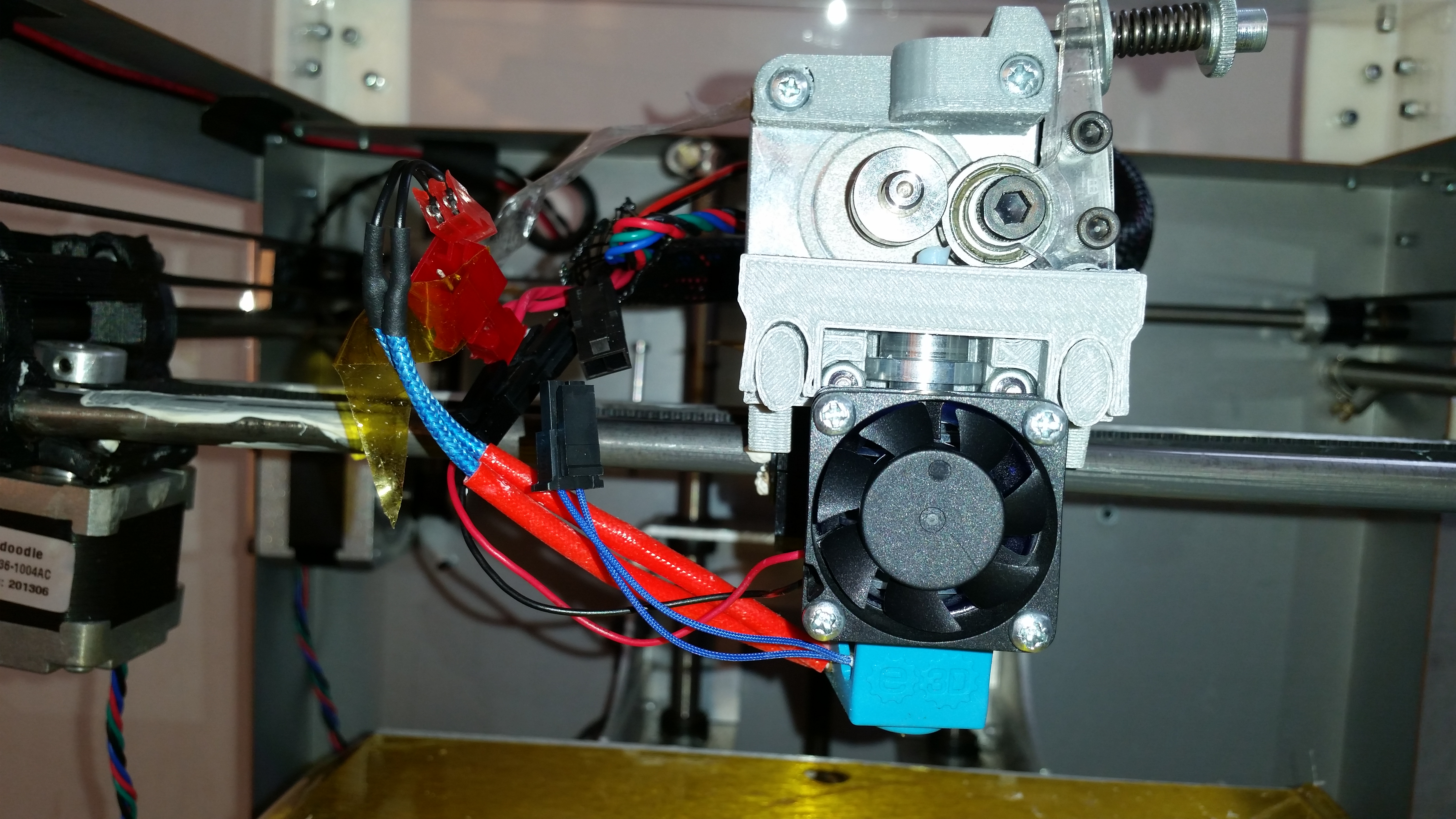

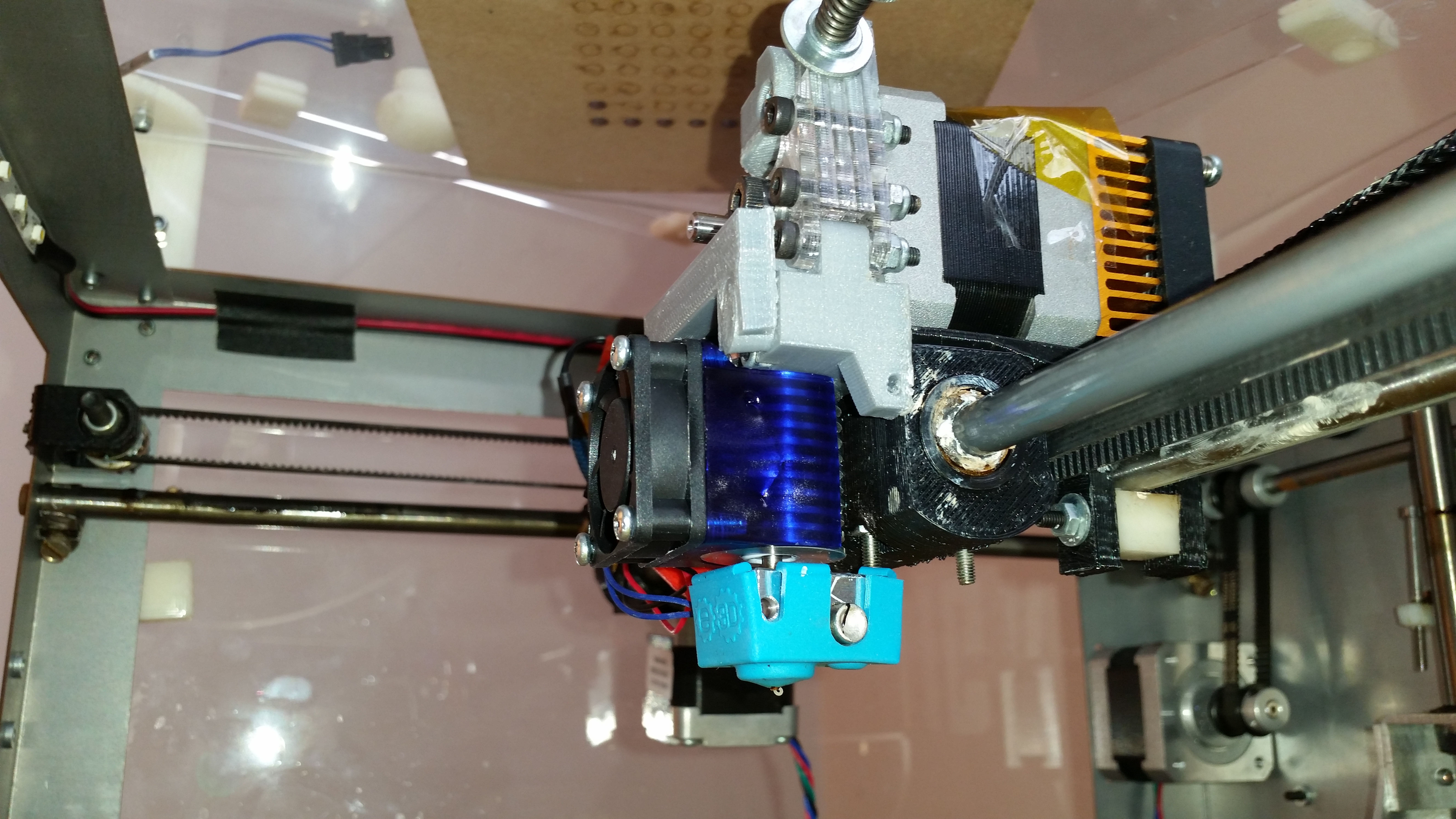

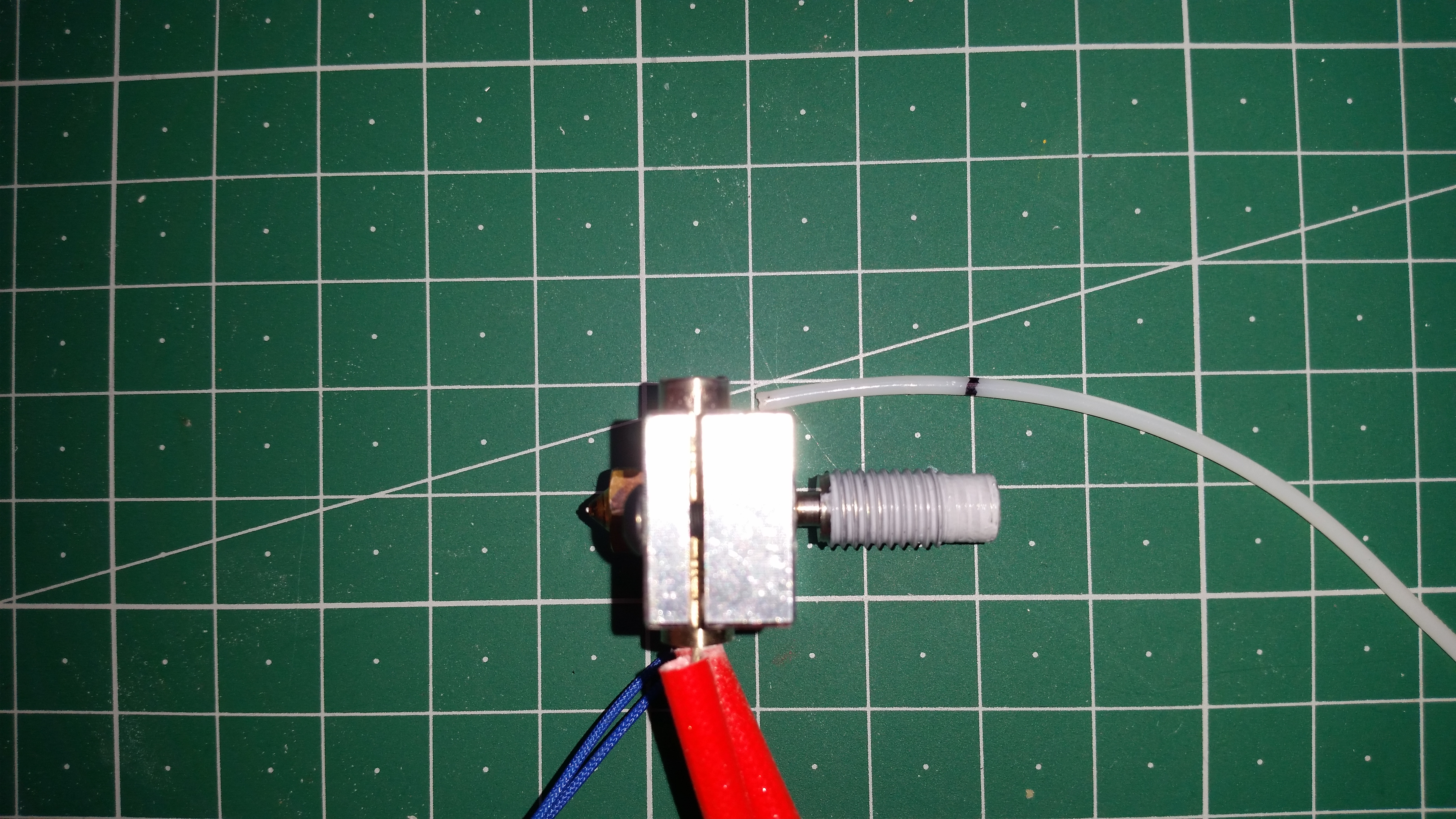

I'm having a bit of issue with this head, I get a print or two out if I clean with acetone but if I let it cool down then I get a blockage. I am printing with ABS and have changed the retraction to 0.5 mm and I am printing at 225 deg C. I have attached a few pictures so you can see what the setup is and how deep the blockage goes.

Cheers

Rob