Topic: Filastruder uneven extrusion rate

Hello all!

I have my filastruder and winder vertically mounted and running.

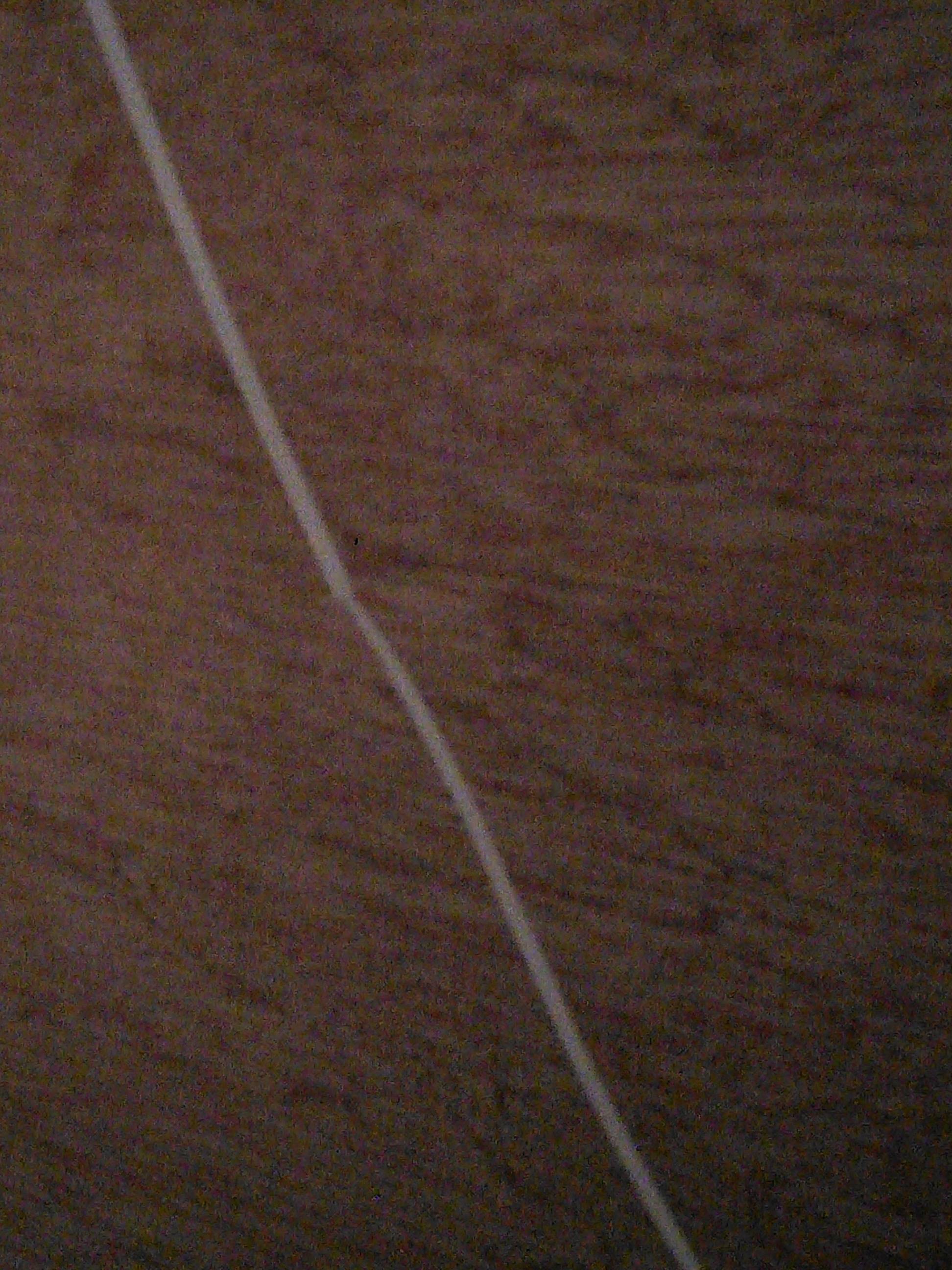

The extrusion rate is very inconsistent, and leads to long time periods of not extruding. The filament slowly stretches as shown in the attached picture (low quality) .

I am looking to get a more even flow rate. I tried running at 185C and 180C. I have tried manipulating motor stall protection board so that the current is around 1.4A to 1.55A but am afraid to go higher. Currently no melt filter is installed as I clear out the system. The extrusion fan seems to be cooling well.

I have a feeling it has to do with heater placement. I will get no extrusion, but then if I turn motor on and off, it extrudes fast (12 inches in 30 seconds)

Any suggestions are welcome!