Topic: Solidoodle 4 - Problem feeding filament

Hello Everyone,

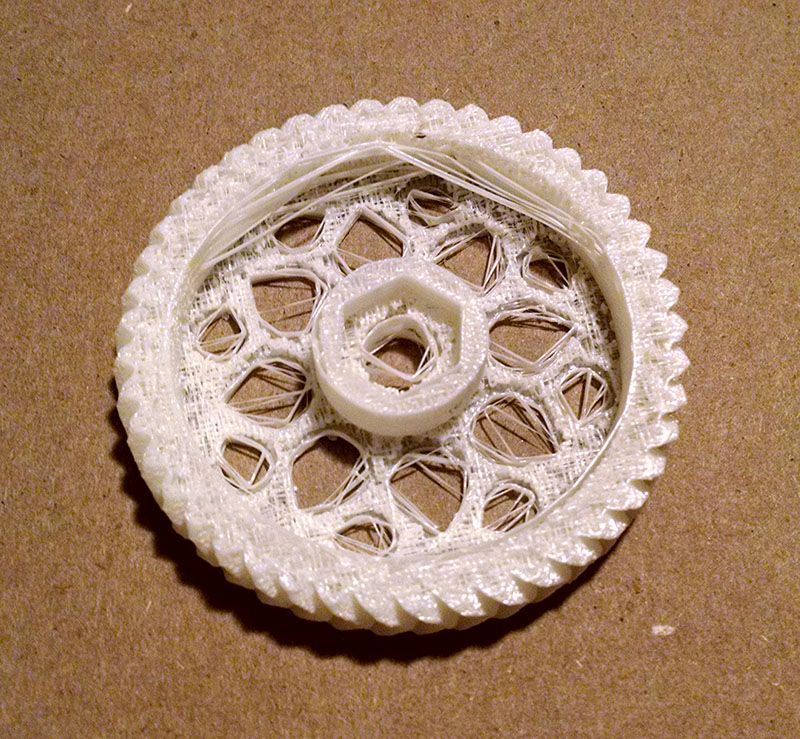

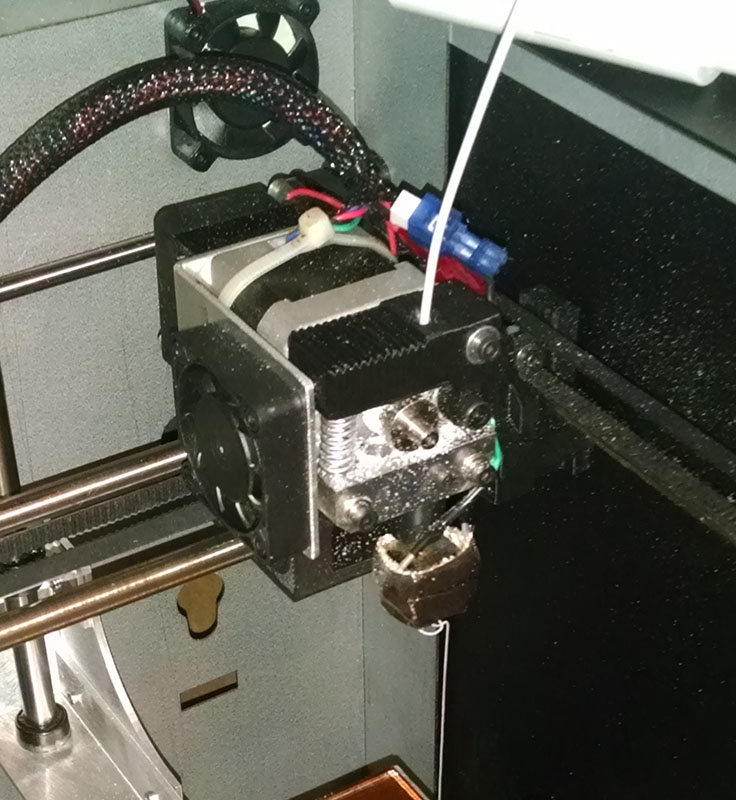

I have a stock Solidoodle 4 that appears to be having issues feeding filament. I took the pressure arm off of the extruder and cleaned all of the filament particles that were accumulated and placed the arm back in position and tried printing the gear whose picture I have attached. It was printed at 90% infill. I am also attaching a picture of the extruder after making the test print. When the test started, there was no sign of filament shavings. Obviously the extruder feed mechanism is chewing up the filament without pushing it through. The temperature was 220 and I was feeding ABS.

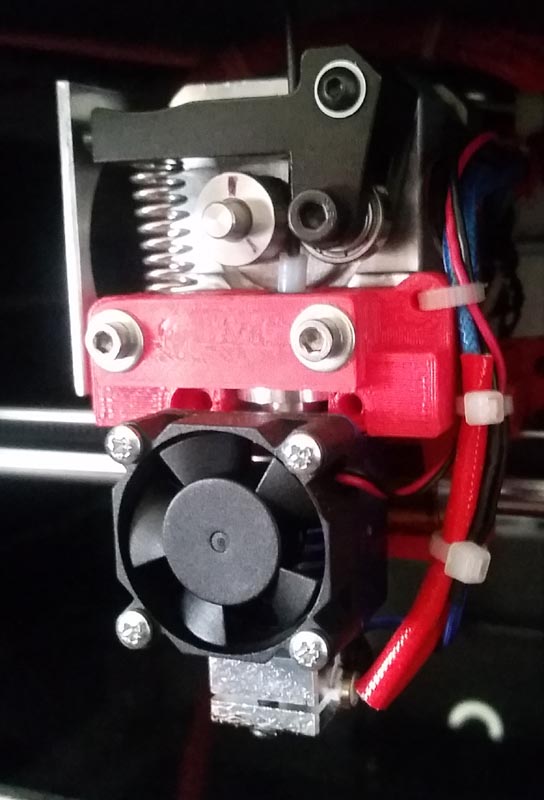

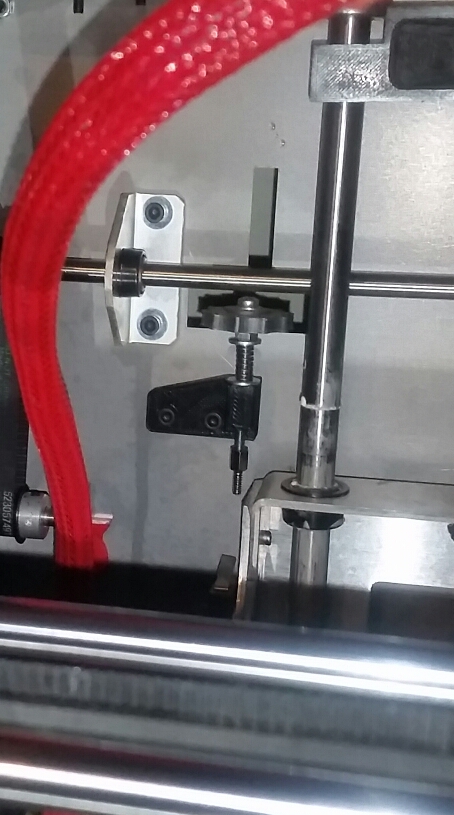

Can anyone tell me what I would need to do to fix this? Should I move to a new extruder altogether, and if so, what is a good one that will readily install on the Solidoodle 4?

Thank You!