I tried to hook up a part cooling fan over the weekend. Got the wires run through the cable chain, all nice and neat. printed up the mount & shroud on #1 got it all installed on the printer. Looks pretty good.

Make the connection on the controller board to D9 - the spot the reprap wiki says to hook the fan to - which should make it automatic g-code enabled... except it doesn't work. At all...

The firmware for this thing is a "custom" revision of Marlin. And I knew there were some strange things done with it because right rear is not only home, it is also 0,0 (instead of left front being 0,0 as most host software dictates). This is not a huge deal, it simply means that everything is rotated 180 degrees from what is seen on the computer screen.

But after I started poking around a bit more and comparing it to the version of Marlin I have on both of my SD4s, I have discovered that entire sections have been completely removed!

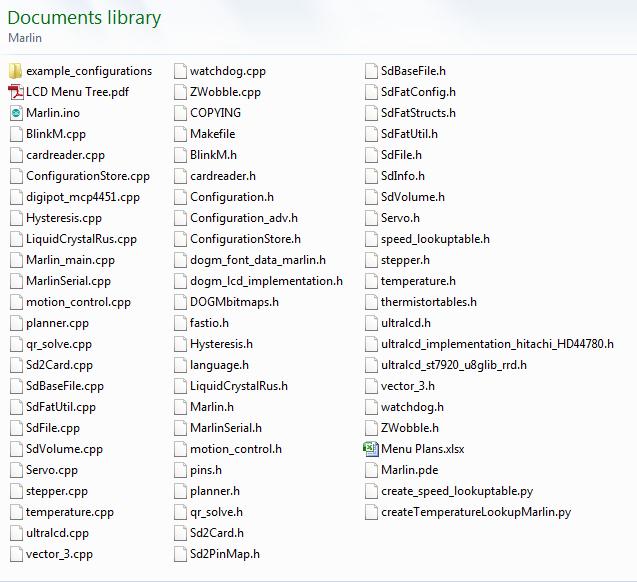

this is the file list for the SD4 version of Marlin:

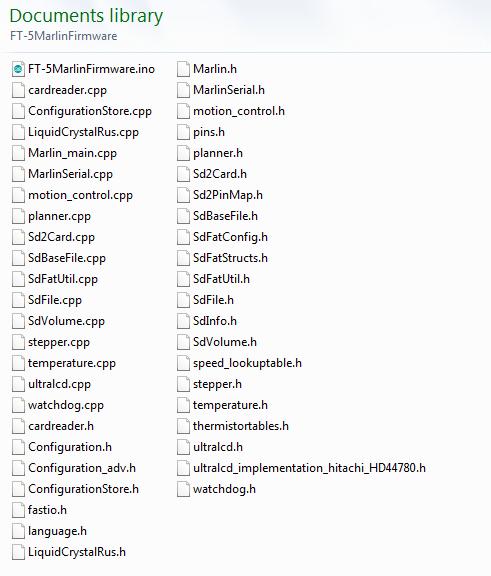

and here is the file list for the FT-5 version...

Now I can understand removing stuff for your own personal use, but not when this is supposed to be a public release for a kit printer. The makers of the kit have no idea what the end user is going to want to do with a kit - such as upgrading various components like hotends, beds, adding things, etc...

One of the things I noticed missing were several thermistor table references - WHY? That makes absolutely NO sense whatsoever!

The firmware for this printer is so butchered I don't even know where to begin.... I do not understand the thinking behind what was done to this.

My thinking at this point is to make a copy of my SD4 firmware and set it up for the FT-5 - seems to me this is going to be the easier route for me to take to get things the way they "should" be...

Rant over...

SD4 #1 & #2 - Lawsy carriages, E3D v6, Rumba controller board, mirror bed plate, X motor fan, upgraded PSU & Mica bed heater

SD4 #3 - in the works ~ Folgertech FT-5, rev 1

Printit Industries Beta Tester - Horizon H1

![]()