Topic: after E3D V6 upgrade, over extrusion problems

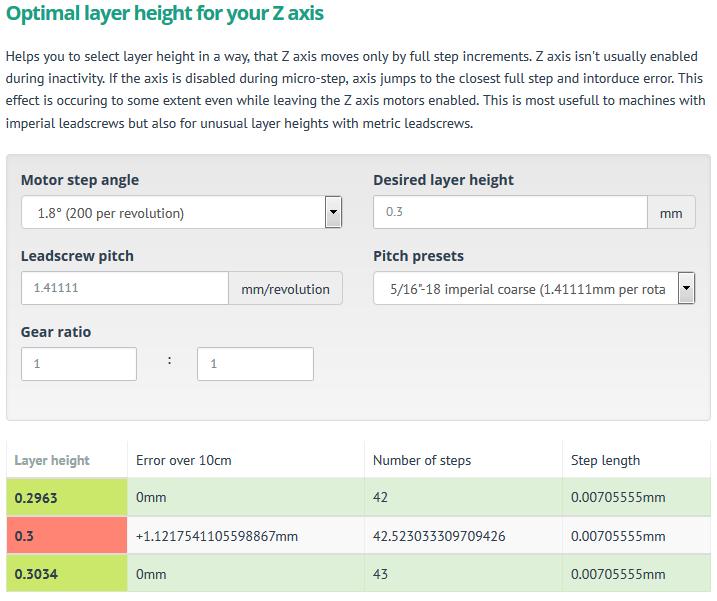

I did the part 2 of my SD4 overhaul a few week ago, but can't seem to get it calibrated properly. My first round was bearings and idlers on y-rod, m3 z-screw, smoothie clone (drv8825 steppers) and pcb bed heater. Had been printing with that for a while now and was reasonably happy. Now the second round was lawsy/pirvan carriages + gt2 belts, e3dv6 and 400 step extruder motor, all in one go, as per all the recommendations ![]()

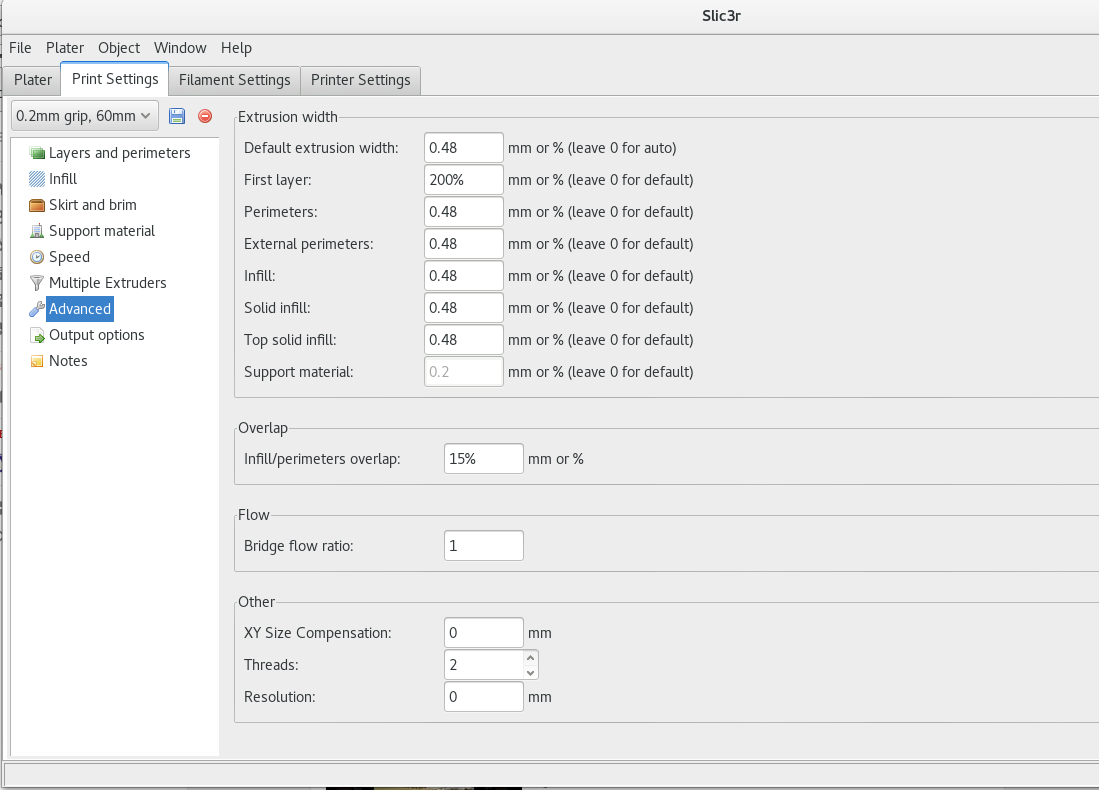

I think I got the basic calibration parameters right: Calibrated extruder steps/mm and filament diameter, printing 0.2mm layers, 0.48 extrusion width, 0.75mm retracts and 238C temp and usually running @ 60mm/s. Calibration cubes come out 0.48mm thick with beautiful walls. Circles are round.

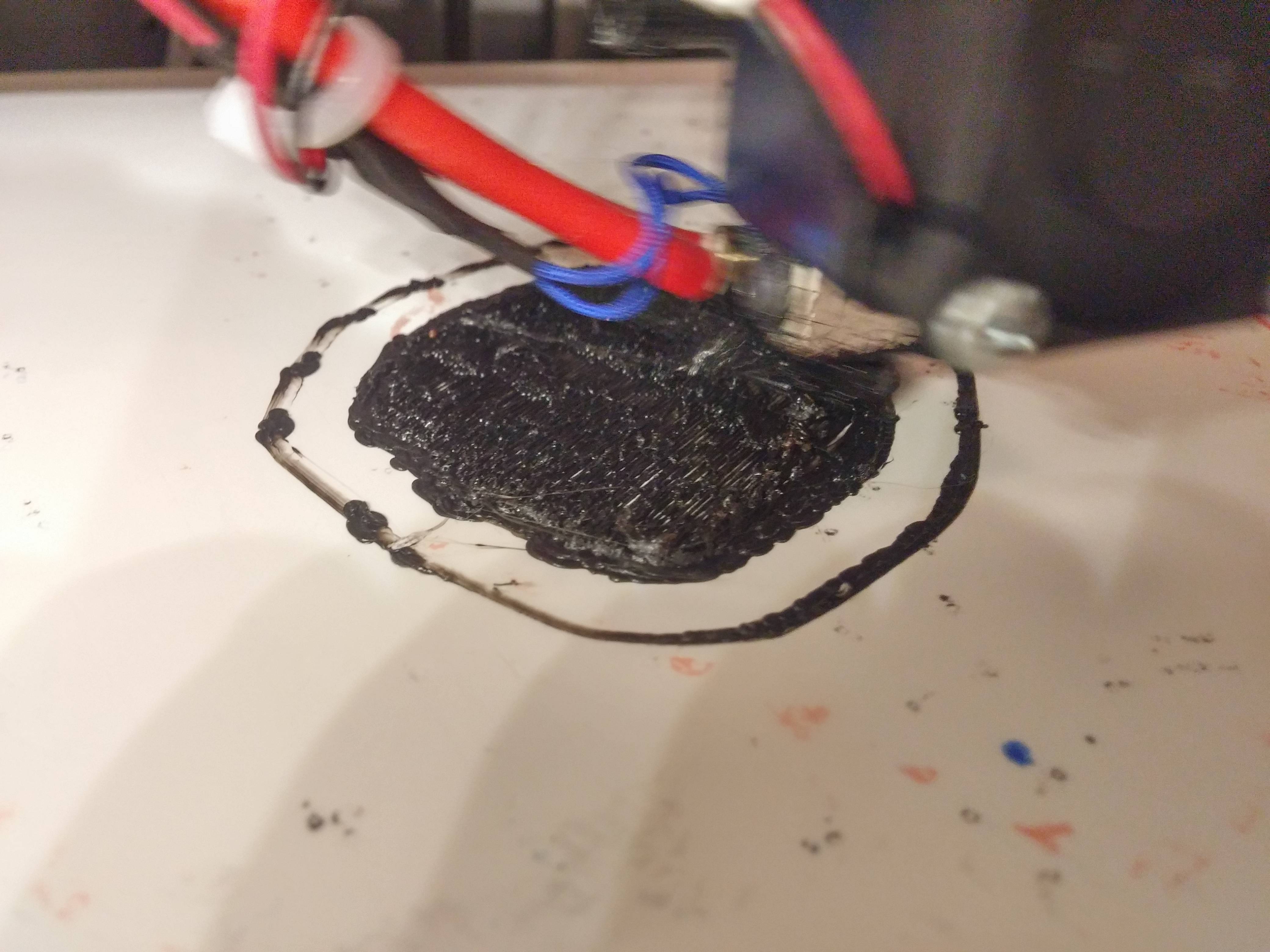

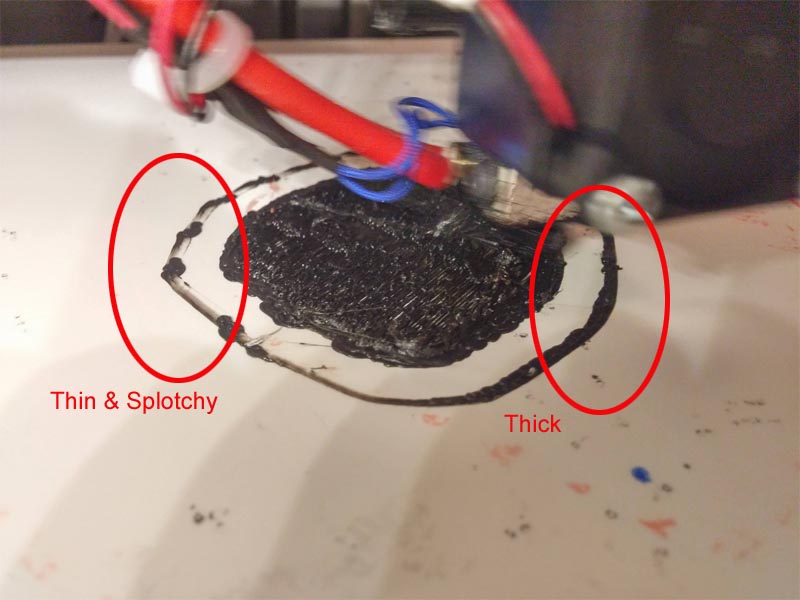

My problem with the new setup is substantial over extrusion. With this setup, I'm unable to come up with an extrusion multiplier that produces 0.48mm walls on calibation cube *and* clean 100% infill prints. I didn't have this problem before. I'm attaching a couple of pictures, printed with 100% infill and extrusion multipliers producing < 0.48mm single walls. The printer draws way better than before the upgrade, but I'm not sure how to correctly deal with the over extrusion. I'm begining to wonder if there's something I'm not quite understanding wrt. controling the amount of plastic pushed.

Would be greatful for ideas on what to try next.

tia, veehoo