Topic: [ABS] Generic white pellets

Resin: ABS Generic white pellets

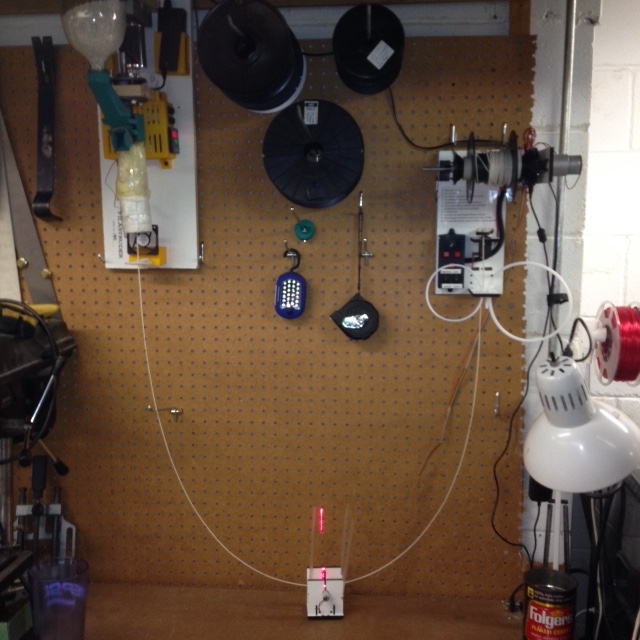

Equipment used: Filastruder #1956 ver 1.6 with 2.0 motor, melt filter, full barrrel insulation, vertical mount with filawinder. Beverage straws were placed over the PTFE tubing was on the laser sensor to guide the filament better. Printer is DaVinci 1.0 with custom firmware, Bowden carriage, heated glass bed, and E3D hotend.

DETAILS:

Tip Diameter: 1.6 mm

Extruded temperature: 186°C (in hindsight, may have been better at even lower temperature)

Speed of extrusion: 15" / min

Filament diameter and tolerance: 1.65mm +0.03/- 0.0mm

Pre-extrusion processing: Food dehydrator for 4 hours.

Extruded vs purchased: Very flat (non-glossy) smooth and consistent finish on the extruded filament. Not brittle at all. Not as good as the best purchased filament but superior to all budget filament (magicCube, JustABS, etc….) On par with ESun.

Printing: All printing was performed on a 90 degree bed with sugar/water coating. Adhesion was fine, no warping and prints easily released when cooled. The single-wall 100mm column was printed at temperatures from 240 to 213C (temp decreased 3 degrees/10mm) and .01mm layer height. Layer adhesion was excellent throughout, however there was noticeable curvature at corners above 225C. The 1.5 inch EMT conduit tension nut/filament guide was printed at 215C and .03 layer height with a layer cooling fan for layers <45 seconds.

COMMENTS:

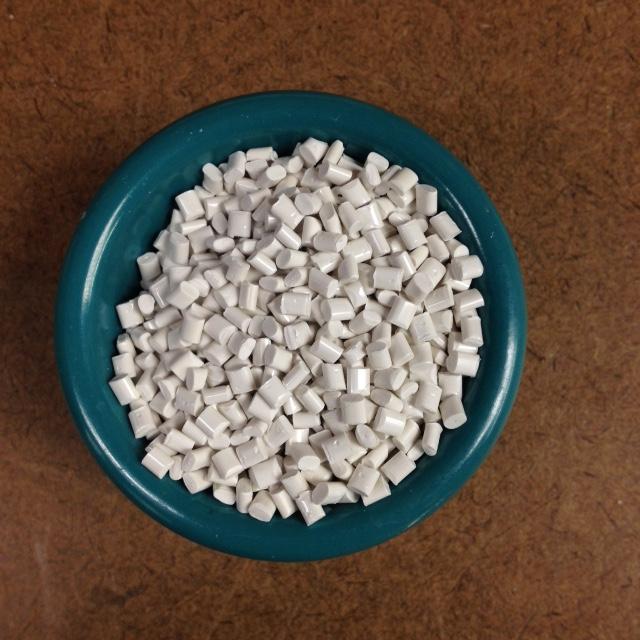

- This material was purchased from an E-bay seller in Missouri (Carl’s Industrial Salvage). I received this as part of an assortment of materials that I wanted to test, but this specific product is available from $2.39 to $7.50/lb shipped in amounts from 1-22 lbs. The pellets were in a zip lock bag. The pellets are consistently sized and somewhat flattened. Evidently, they can also be used as kitty litter in a "Cat Genie" according to the seller.

- Extrusion was performed at 186C and resulted in 15”/minute. I measured at approximately 1 foot intervals over a 10 foot section after PID tuning and with the filawinder running smoothly (7 spots at 1.65, 2 at 1.66, and 1 at 1.68). This filament seemed much more susceptible to stretching/distortion until the winding process stabilizes. I have approximately 2.5 feet vertical drop in my setup. This same arrangement and temperature results in 19 inches/minute and 1.70mm diameter MG-94 filament.

- The extruded filament is a flat, off-white. Based on the initial pellets being a glossy white, I suspect that extruding at a lower temperature may result in a brighter white. Printed parts were identical in color to the extruded filament. Definitely prints well at a lower temperature than any of the ABS I have previously used.

My setup.

Pellets.

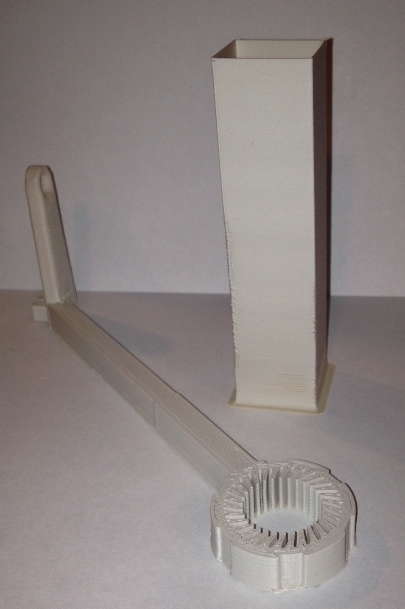

Filament.

Prints. (These are on a white copy paper background)