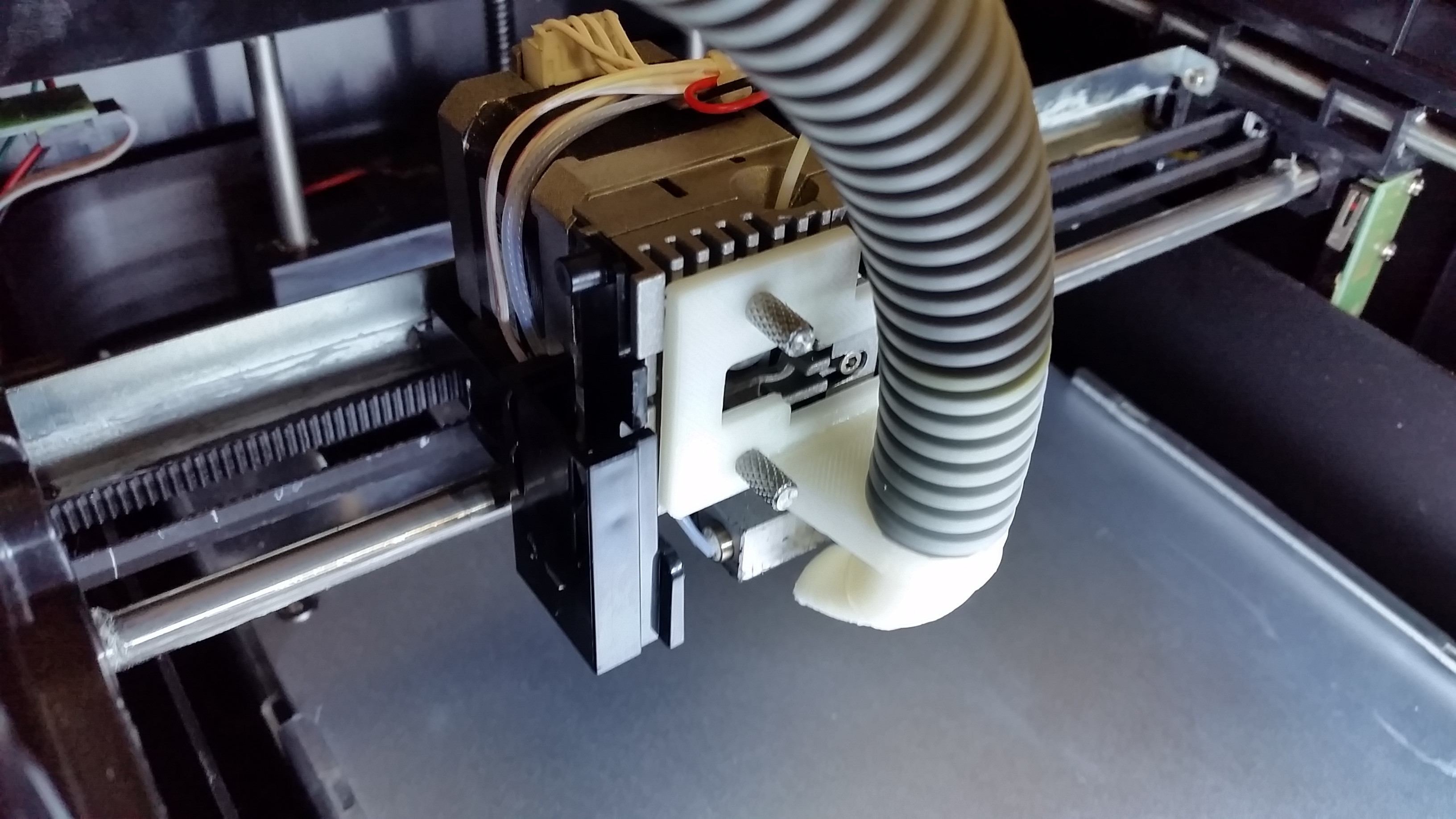

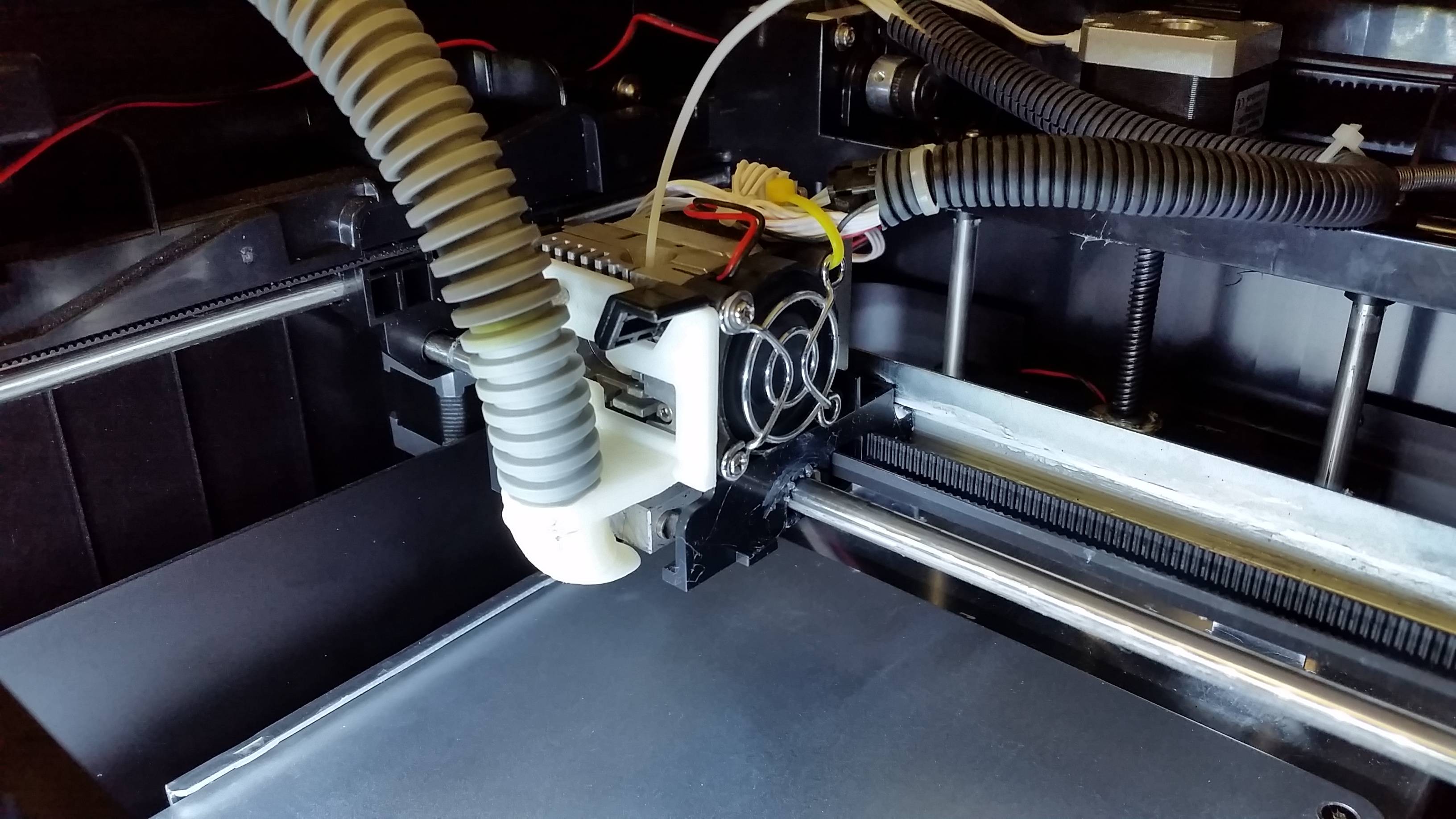

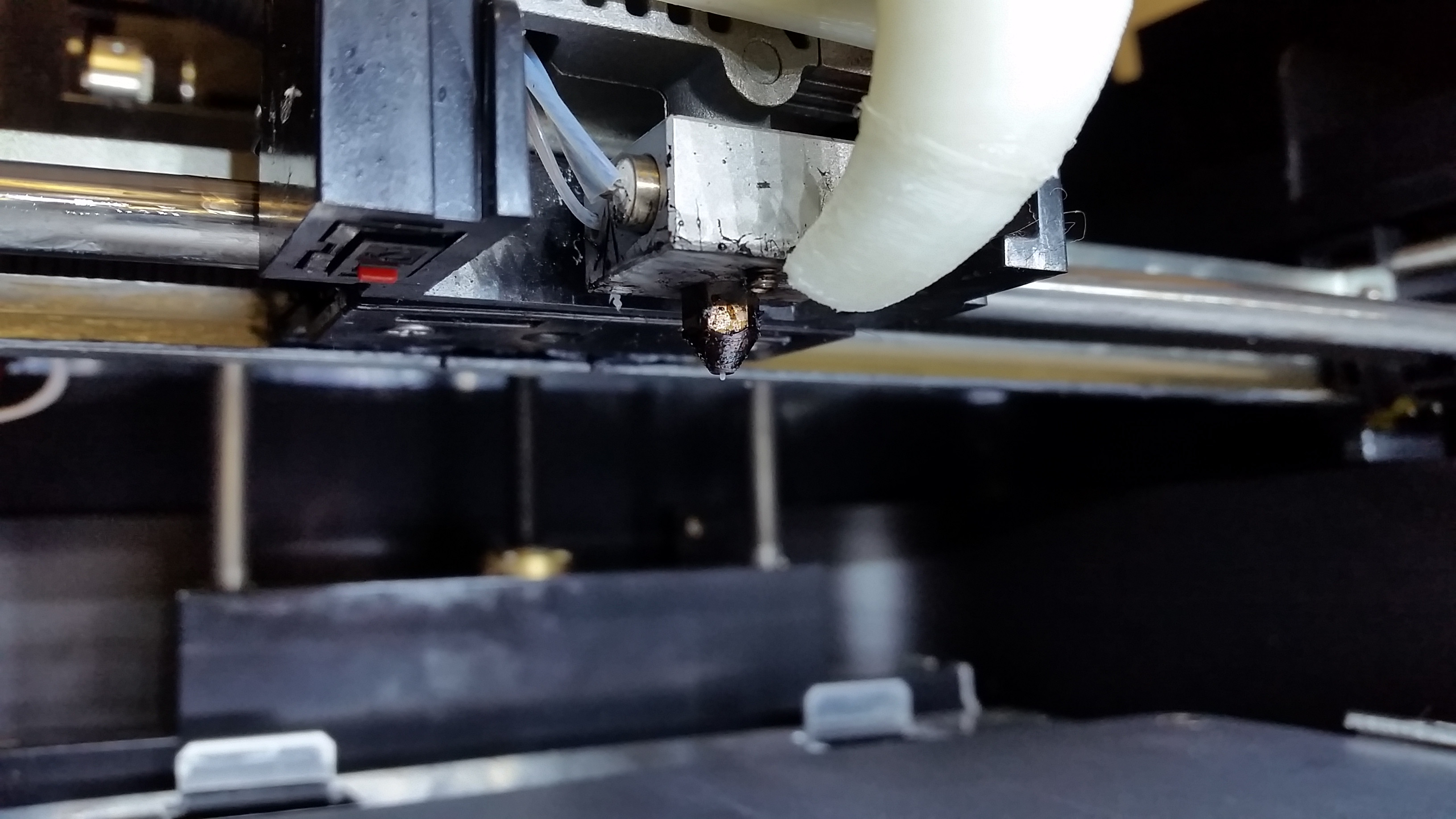

Topic: Extruder Cooling Fan with Hose Connection

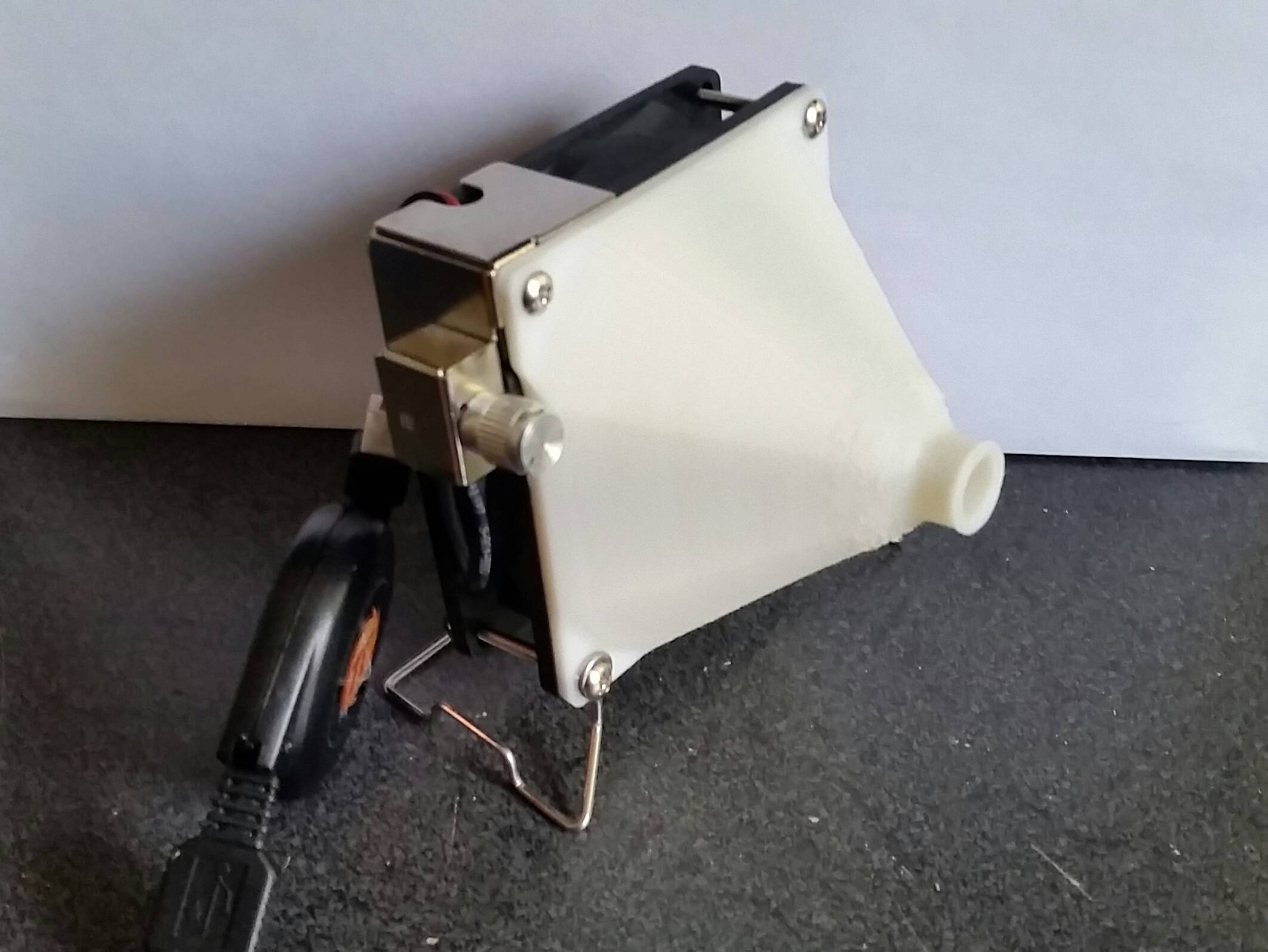

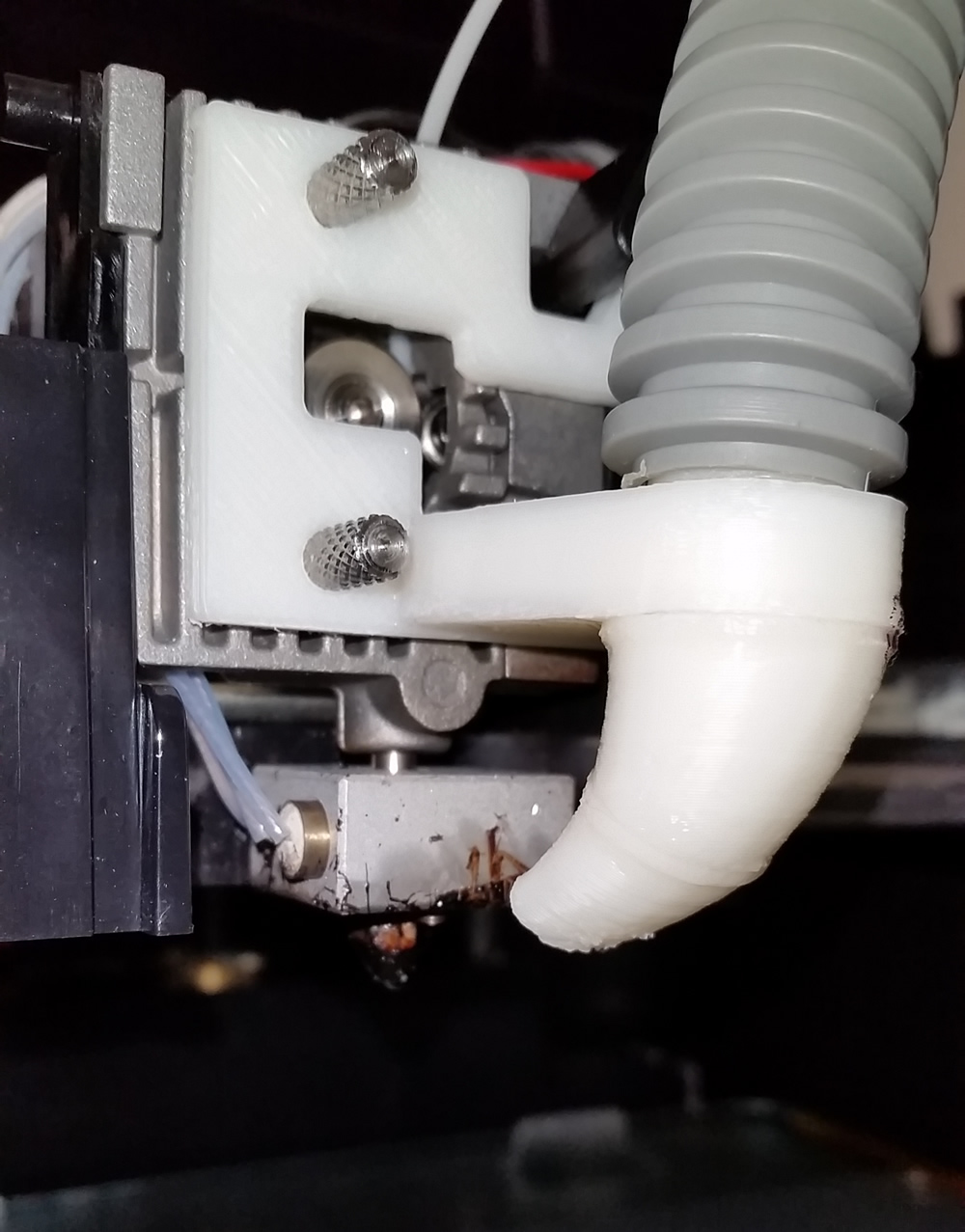

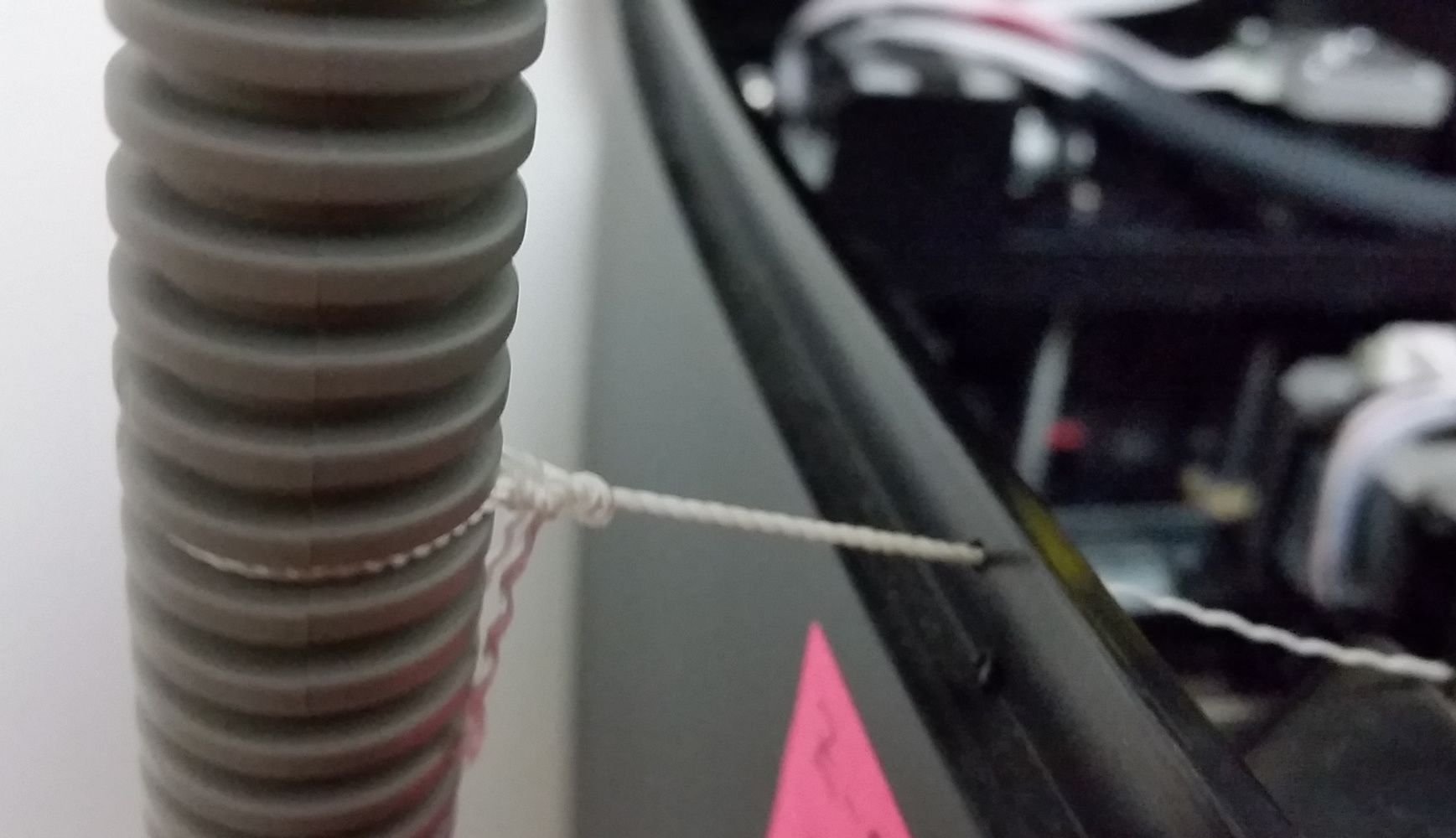

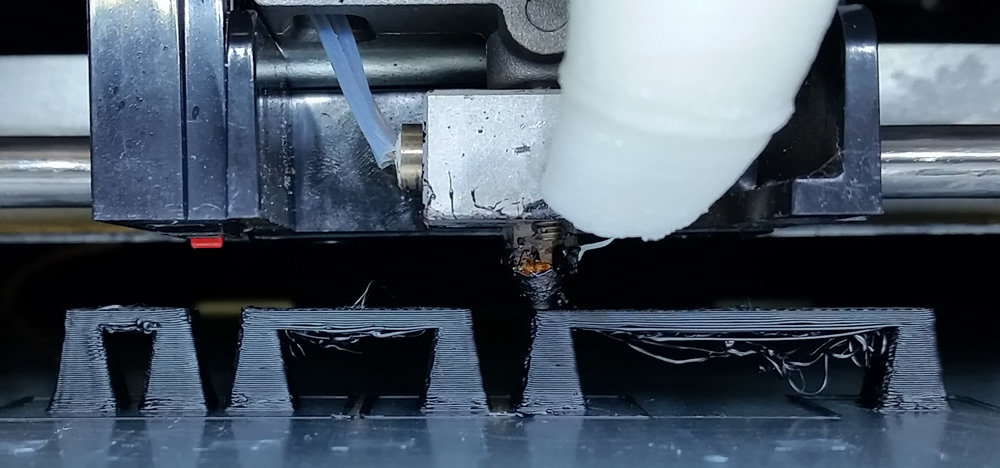

Unlike many other printers, the Press doesn't have much room on the print head for accessories like cooling fans, so you must either choose a very small (~25mm) fan, which doesn't move much air at all, or... why not just pipe in air from a larger fan sitting somewhere outside the printer?

I downloaded an assembly from Thingiverse that holds a 25mm fan, but the airflow was almost non-existent, so I started down this path.

I'm still modifying these parts for fit and effectiveness, and I've yet to print the cone that will go over the large fan (connecting it to the other end of the pipe) but I will post updates and eventually the STL files as this project progresses.