Topic: bondtech QR

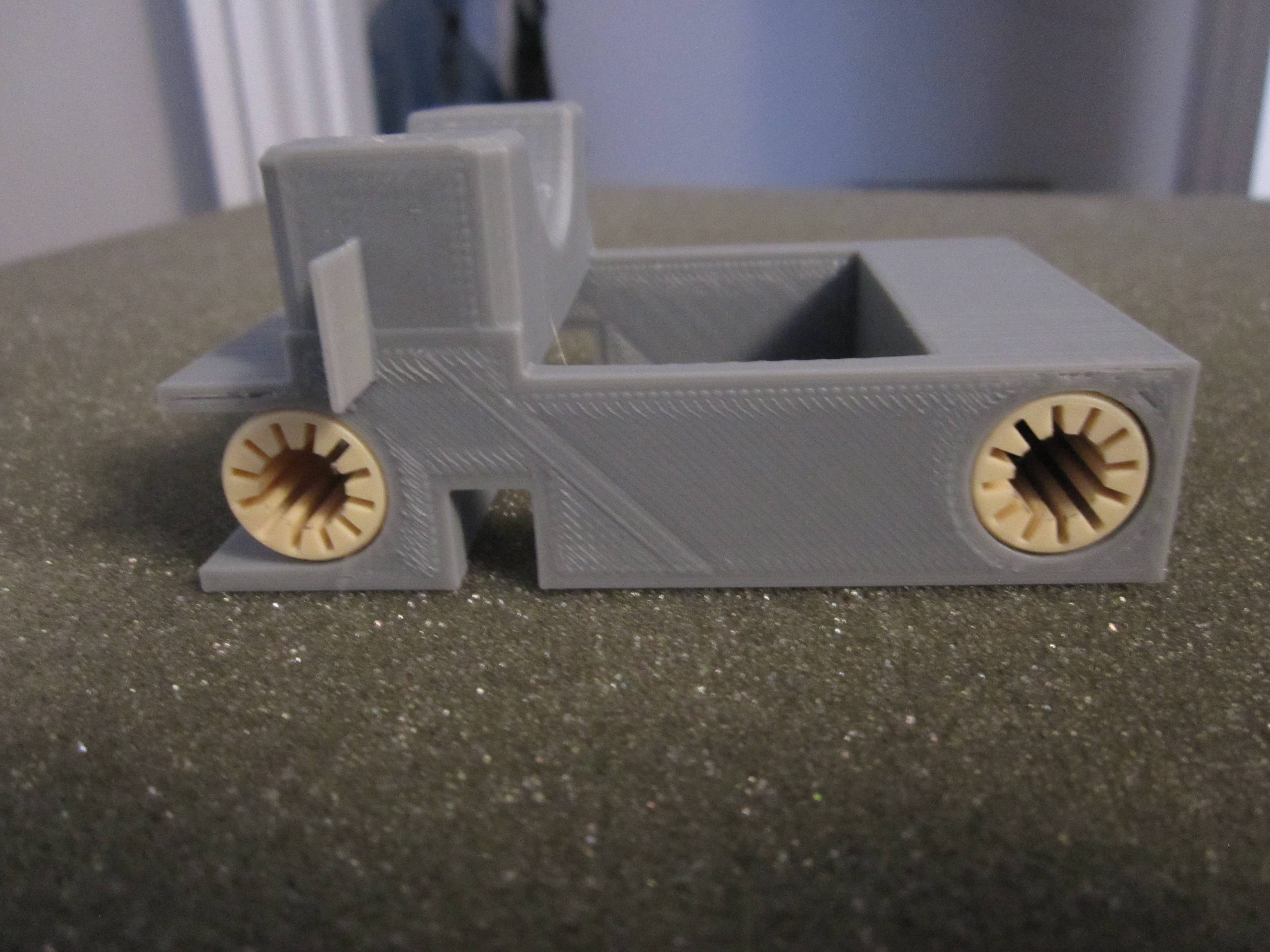

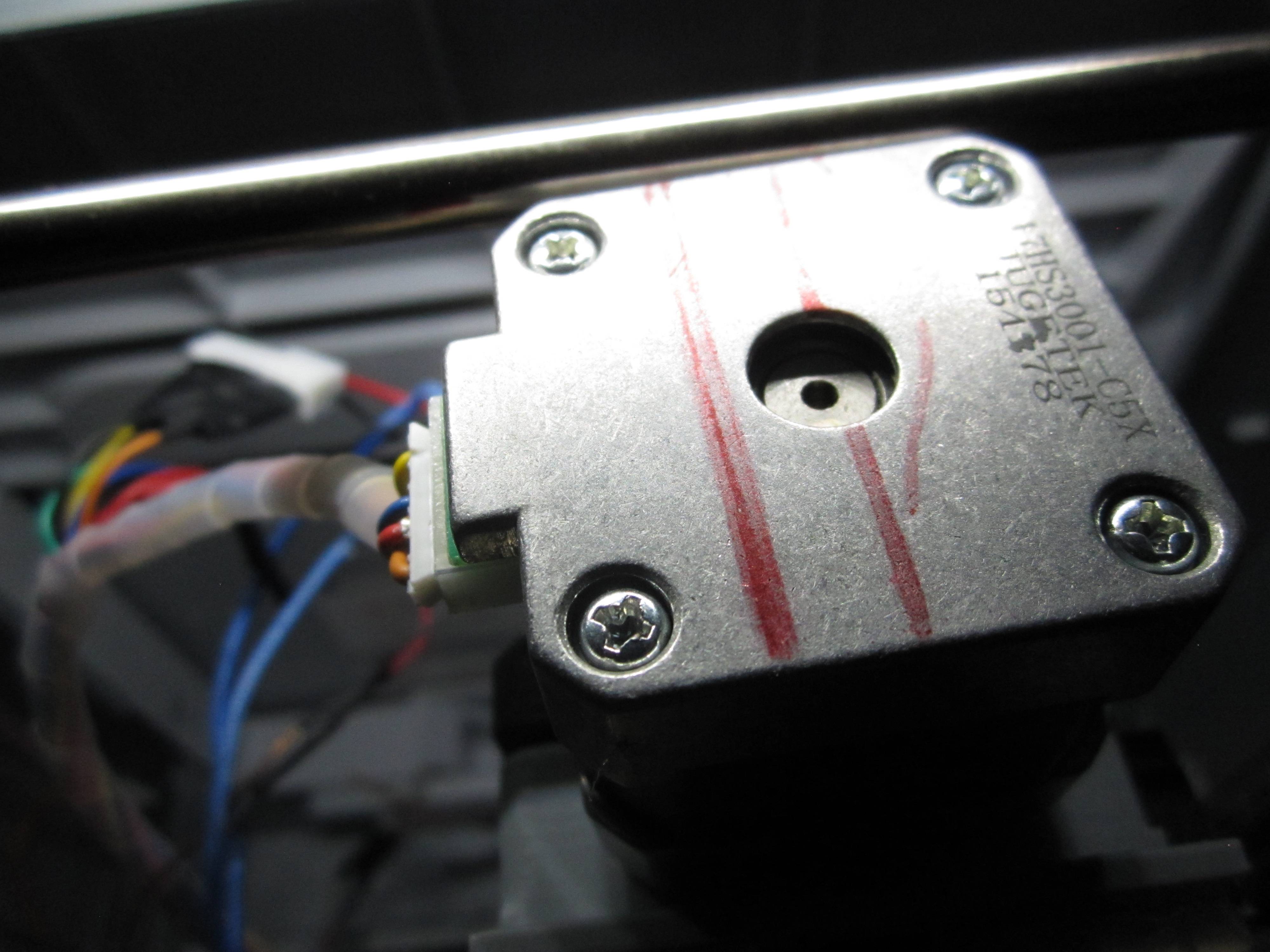

Well my printed extruder popped the shaft holding bearing the holds the filament against the drive gear. I haven't had as much luck with printed extruders and fortunately I had a bondtech qr that I was going to put into a printer I am still designing (order some of the parts I will need for it but not finished designing it)

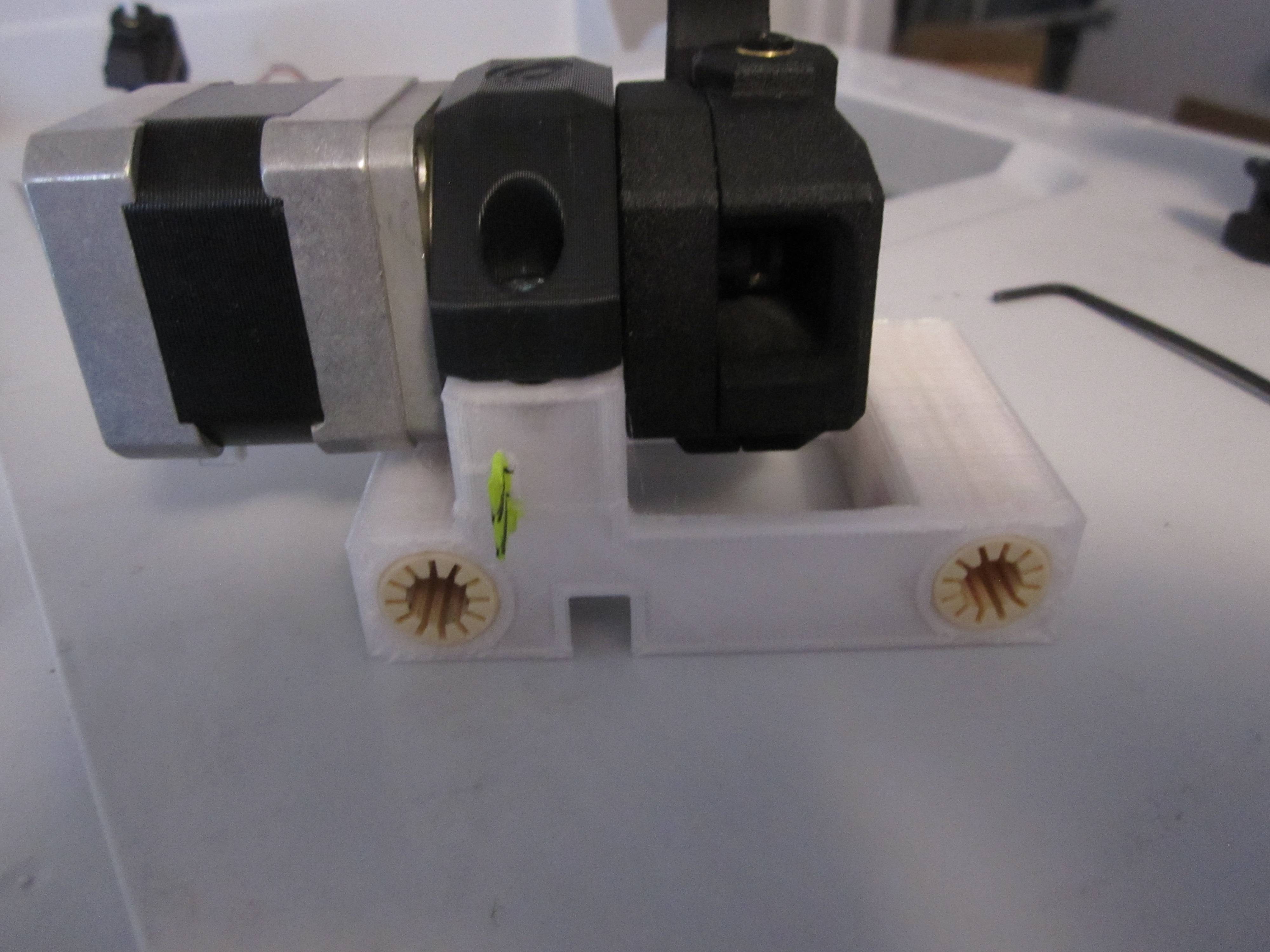

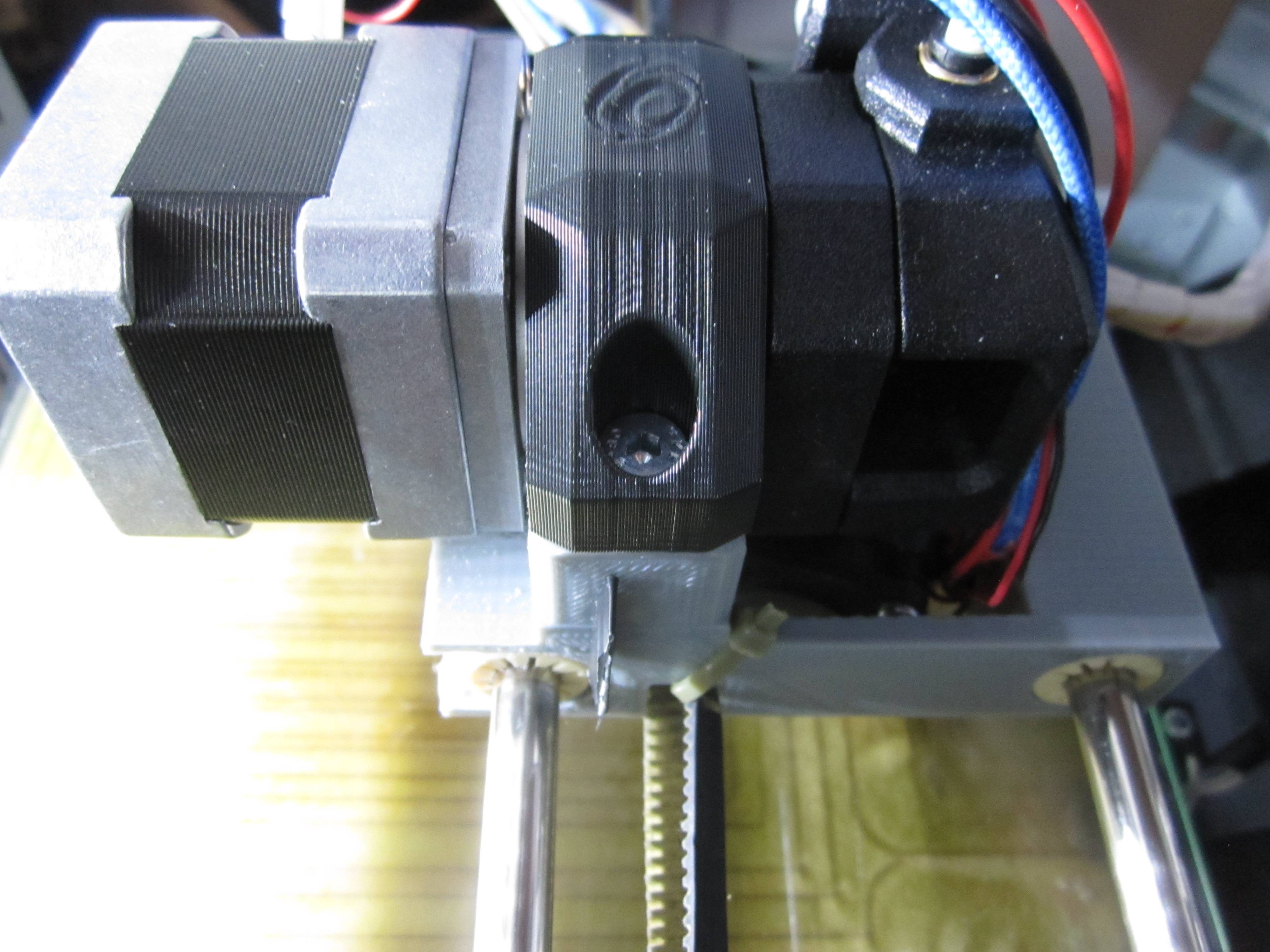

So I currently have a that extruder put in the davinci aio.

If you do plan on putting one in one thing to note is that the middle pins connecting the stepper motor need to be swapped as the pairs are not wired the same as the stepper motors in the davinci.

it will also limit some of the y travel since it is 42 mm longer. Opps noticed I put the wrong axis. any way after mounting it I have 29 mm less y travel some of the

about to do some test prints with it