Topic: Bridging Gaps

I'm trying to improve my printer's ability to bridge gaps, which is to say, I'm trying to make my printer bridge gaps in any capacity. Now of course, if enough filament piles up, it will eventually bridge the gap, but it's nothing like this beautiful example of a proper bridge.

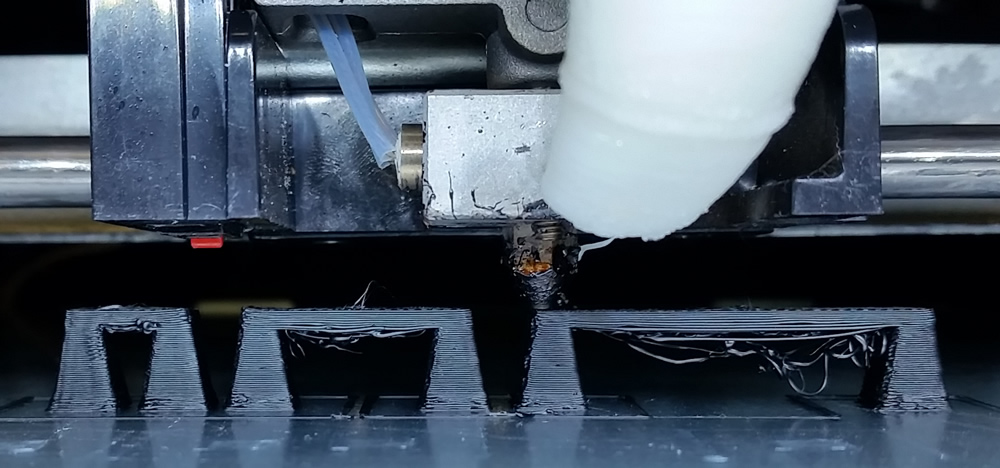

Here is a video of my attempt to create a bridge.

I understand the need to match the nozzle's travel speed with its extrusion speed, but it's not even starting properly. Has anyone else been able to overcome this problem?

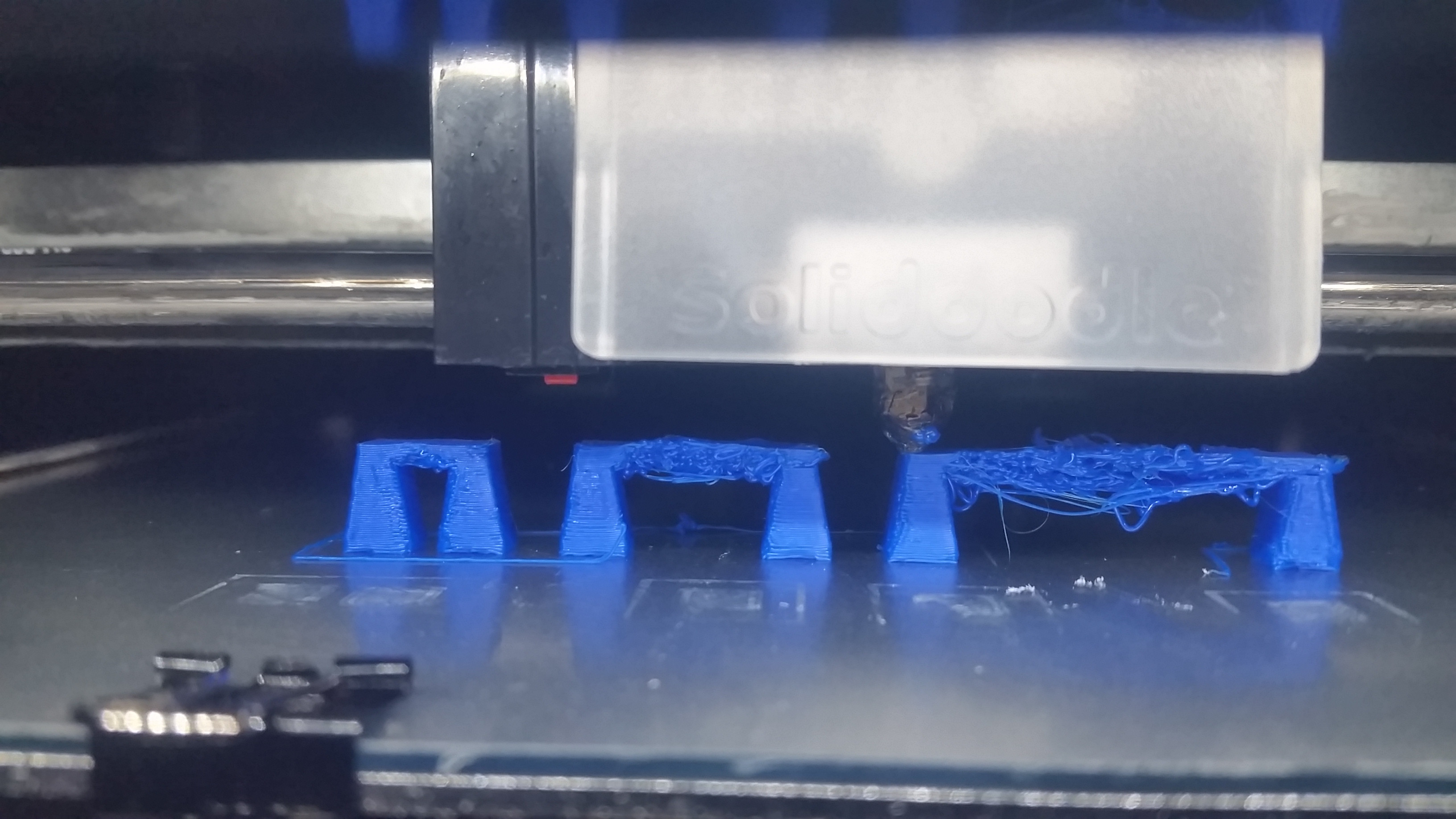

Theirs:

Mine: