I got tired of studying and just took the leap. Ill do e3d later.

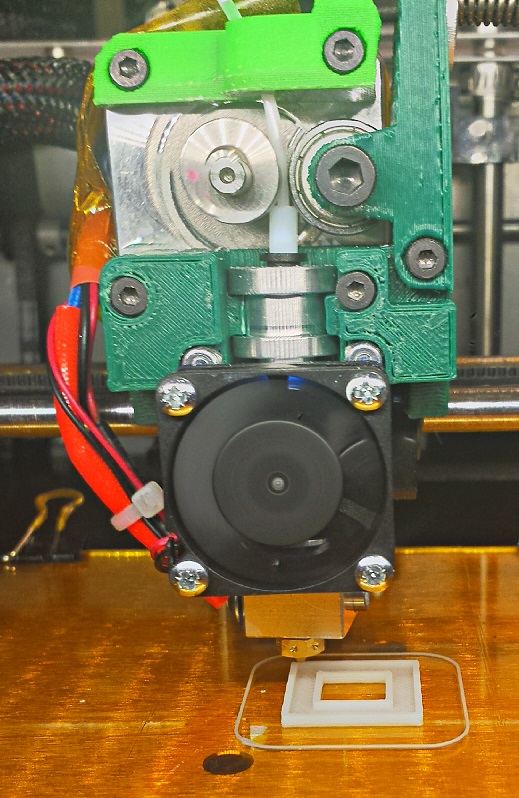

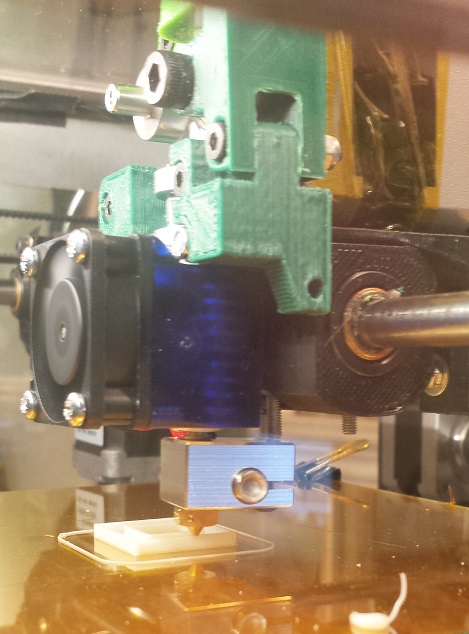

I replaced my jigsaw with the lawsy mk5. Since i couldn't find a good concise list of steps (in text at least...) on removing the old extruder assembly I'll try to give my blow by blow it case it helps someone in the future. I immediately printed another lawsy .. and ill probably print another one tonight.

0a. i stared at the thing for a week (see above

0b. i determined that there was little chance of saving the jigsaw assembly since the minimum number of required screws that needed to be removed pretty much makes it fall apart

1. I disconnected the hotend wires. Note: the quick disconnects have a lock of sorts on the red/blue end. the actual piece that comes out is the tiny white side. pull on that little lever sticking out of the colored side while pulling on the white piece and it will come out really easy.

2. I took off the 4 longer screws that attach the assembly to the stepper motor. Note: the motor just sits on a perch behind the assembly so make sure you catch it and set it aside gently.

3. i removed the 2 nuts visible from the front that attaches the assembly to the perch. I noticed after the fact that the screws go all the way through the perch and can be steadied with a Phillips head screwdriver (the blasphemy !!  ) if the nuts just spin.

) if the nuts just spin.

At this point you should have the entire assembly in your hands. Now to remove the hot end.

4. Remove the 2 nuts that hold the hot end onto the assembly (I now know why it took so long to ship the blasted solidoodles. They must have had a crew of 20 who's sole job is going in with tweezers and pliers to attach these nuts to the captured screws. incredibly frustrating. look for "solidoodle replacing hotends" for tips..)

5. Now you have to deal with the piece of wood around the hotend. I suppose you could cut it with tinsnips or something, but like I said, I wanted a way back worst case scenario. I decided to unscrew the peek insulator from the nozzle. search for "unclogging solidoodle nozzle" for tips. I will add one thing. slide the black insulation off and locate the thermocouple. it looks like a tiny glass bead attached to the nozzle with kapton. if you have to use a wrench, steer clear of this. it is very fragile. In hindsight, This is probably the most dangerous part of the operation.

Now you have everything in pieces. Pick up with the instructions for installing Lawsy's mk5 extruder on the thingiverse page. I ended up reusing most of the screws from the old jigsaw.

I did have to improvise:

1x m3x10mm - for the locking arm - used an old ugly pan screw that was way too big. i cracked the top hole but got a good firm lock on the arm. probably not the best approach

1x m3 x "shorter". for the filament guide, you need much shorter screws than stock. the left one i ended up chopping a bit off of one of the original hotend to wood screws with a dremel tool. for the right end i used one of the bolts from the tension arm assembly.

I was able to use the extra screws to put the jigsaw pieces back together ..just incase.

protip: when cutting bolts, you will invariably screw up the threads (lol ..puns...:) ). Put one or more nuts on the bolt before cutting it. Once cut, removing the nuts you will mostly straighten out the threads. Also it will be a lot easier to cross thread so be really careful. Also the nuts gives you a good place to grab it with a vice while your cutting it.