Topic: Replace Glass Bed with FR4 Perf Board

There will be more photos/videos/details here soon: http://chasenachtmann.blogspot.com/2015 … t-bed.html

I wasn't satisfied with the performance of the glass bed on my Press-- nothing would stick to it. I've seen a bunch of people say to use hair spray or a glue stick, but that's a band-aid solution to me. None of the other 3d printers I've used have needed any special treatments done to the bed to make them work, and I wanted the same to be true for the Press.

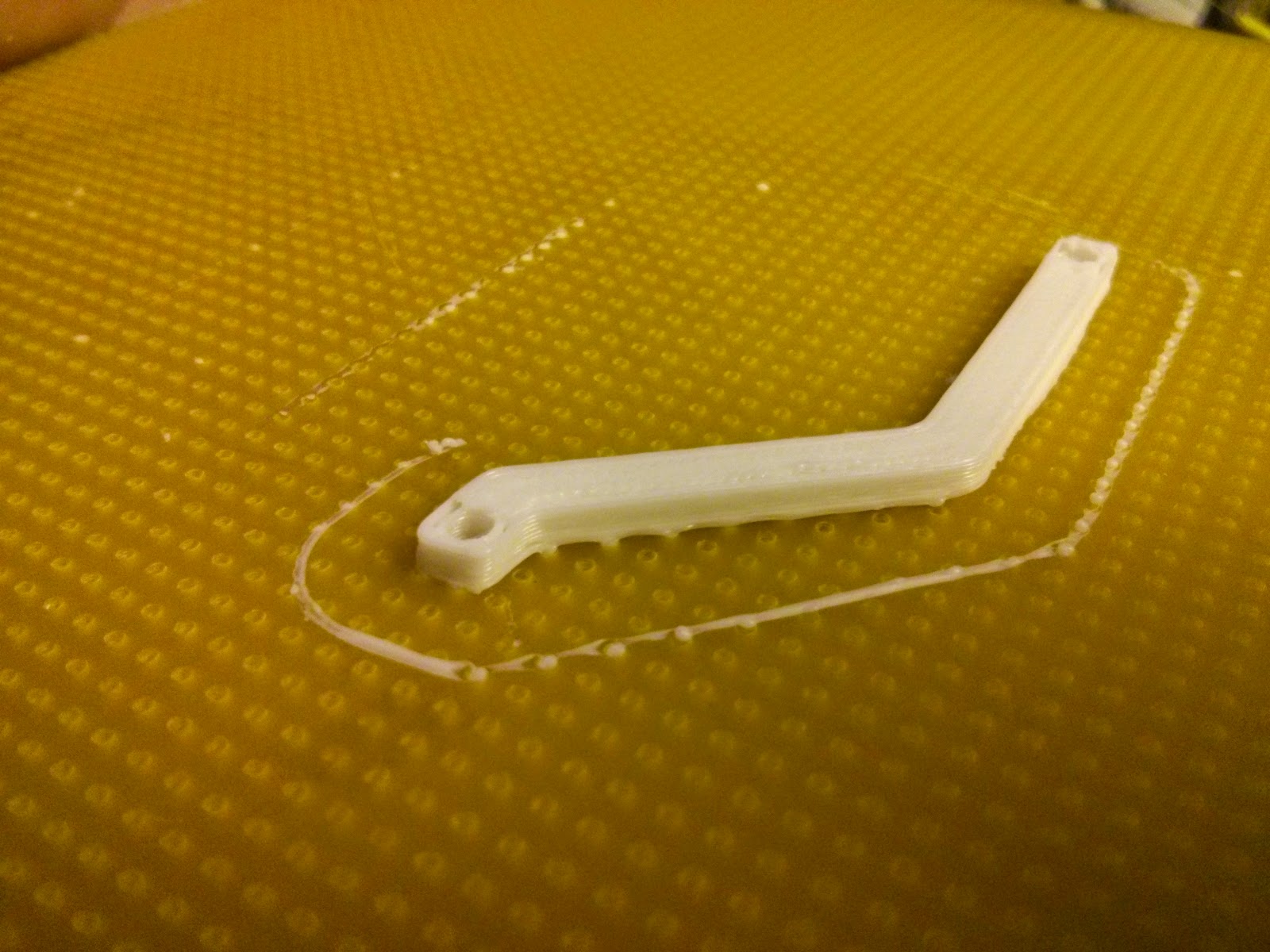

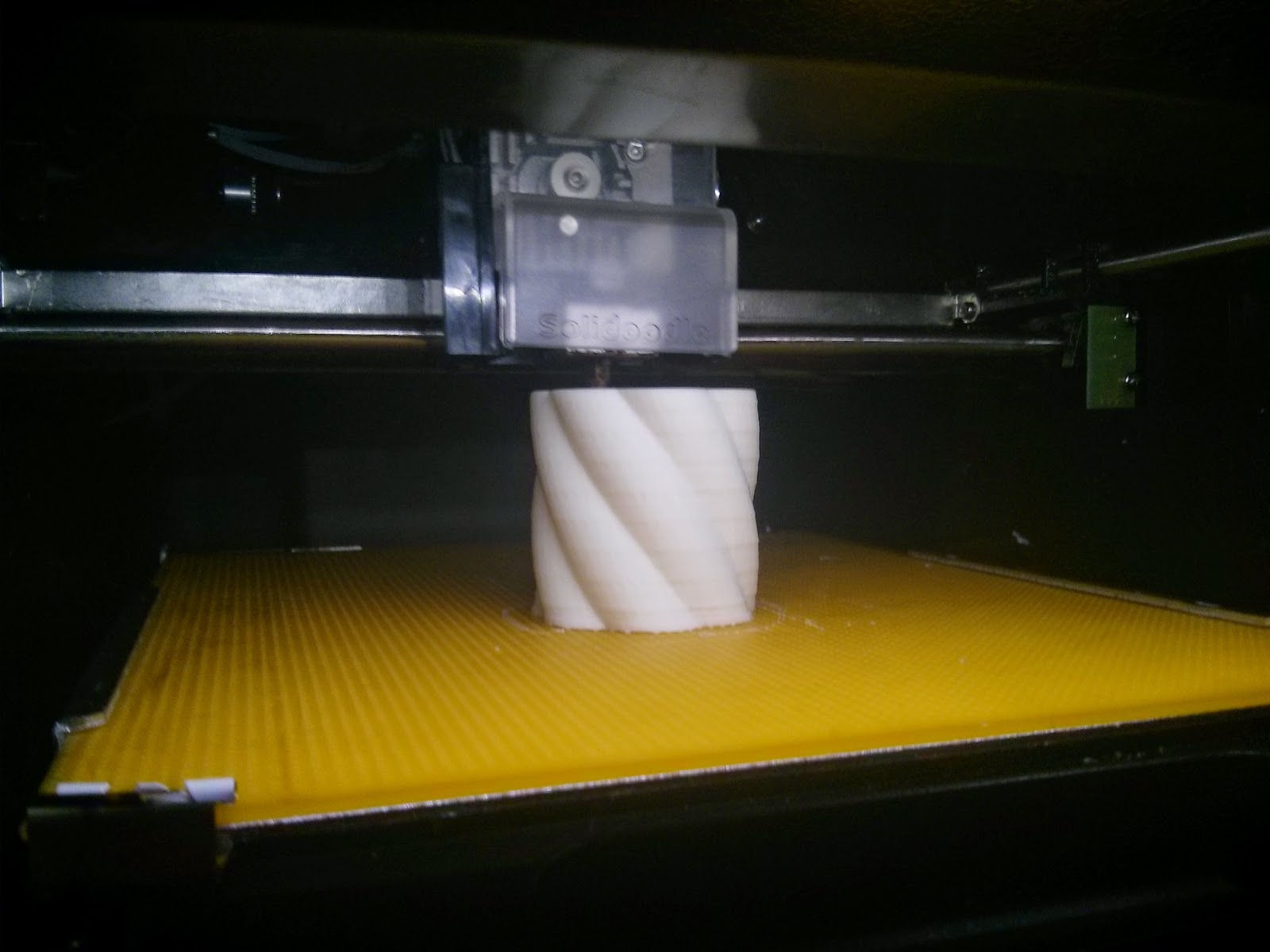

I decided to try the same method of print bed as the Up! Mini 3d printer, which is a perforated board of FR4 (the stuff they use to make a lot of PCBs with). I've used the Up! Mini and have been impressed with it's "plug-and-play-ness". http://store.3dprintingsystems.com/Perfboard

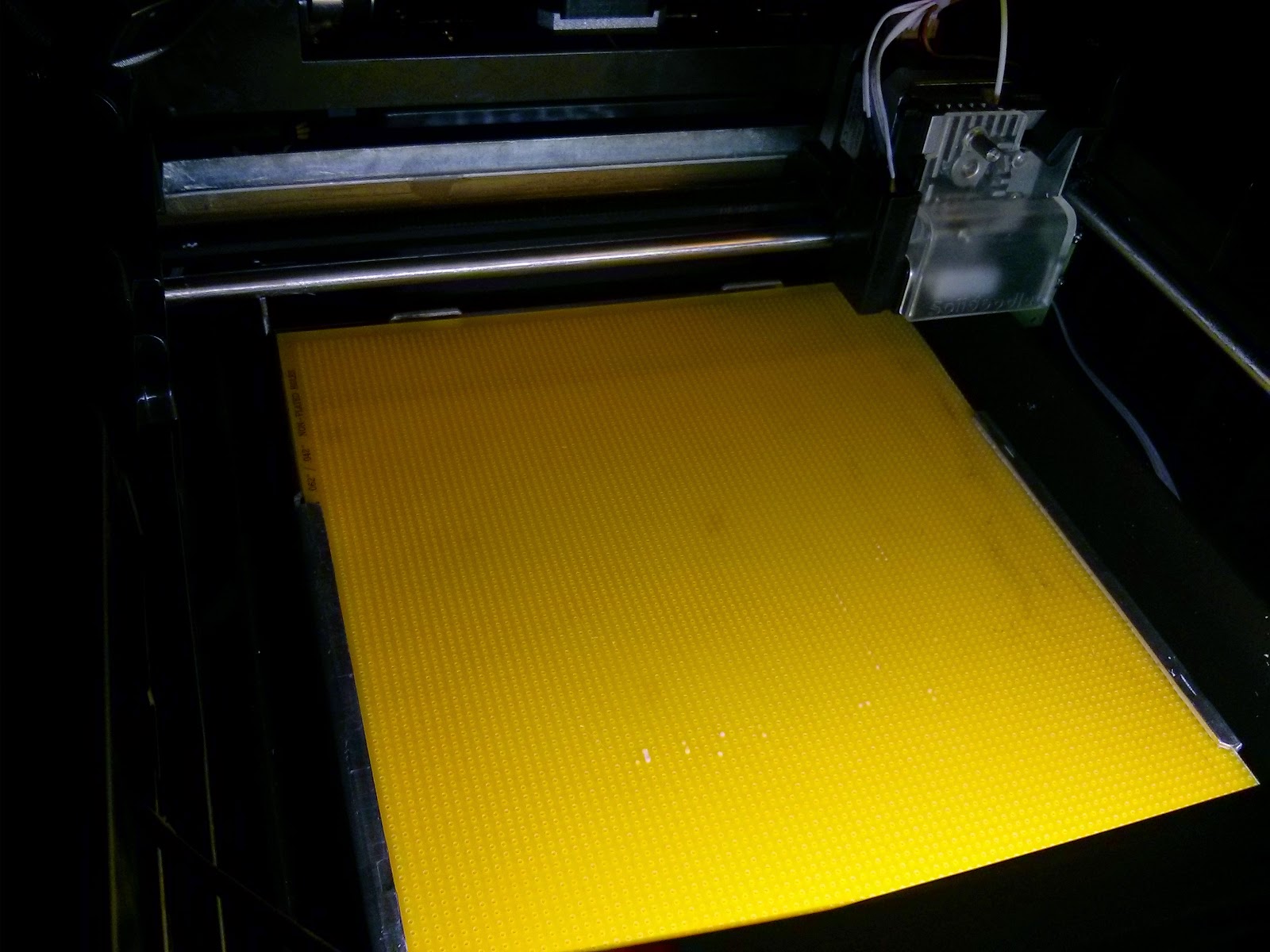

I found this on DigiKey, a 10"x10" unclad FR4 Perf Board http://www.digikey.com/product-detail/e … -ND/480487

I had to trim off one side so it was the width of the original bed, but once that was done it slid right in to the printer.

Was able to print with it right away after a quick z-axis recalibration.