Topic: Z axis wobble

There has been a lot of discussion here and over at

https://groups.google.com/forum/?fromgr … 5YwtCbzw0o

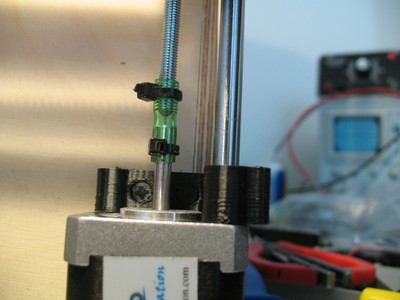

There has been a lot of concern about it possibly being a software/firmware/resolution issue. I don't know how many people have taken the time to closely inspect the z motor in use, but I think we should put to rest anything but play and slop between the leadscrew, motor, and bed. Here is a video that clearly shows the rocking of the z motor.

With the old design, I was able to basically eliminate banding with the design near the top of this thread.

https://groups.google.com/forum/?fromgr … S8Anfz6QwJ

I haven't tried this one yet, but it seems the most promising.

http://www.thingiverse.com/image:193181

I really believe the problem lies in somehow eliminating nearly any slop in the x and y axis with an emphasis on the x. One other solution I am tinkering with is to attach some runners to the front left and right corners of the bed. These would be spring loaded into the corners of the frame and run up and down the frame corners via the spring loaded bearings. Still a huge work in progress, but I will post as I attempt different solutions.