Topic: DIY Smoothing Station

This is turning out to be everything I expected. Check it out-

This is a steel stock pot set inside a tupperware bucket with a small pot filled with coins in the middle. Acetone goes in the stock pot, and the small pot holds the model. The coins keep it from floating in the acetone. I would like to find another option for weighing it down that makes a level surface inside.

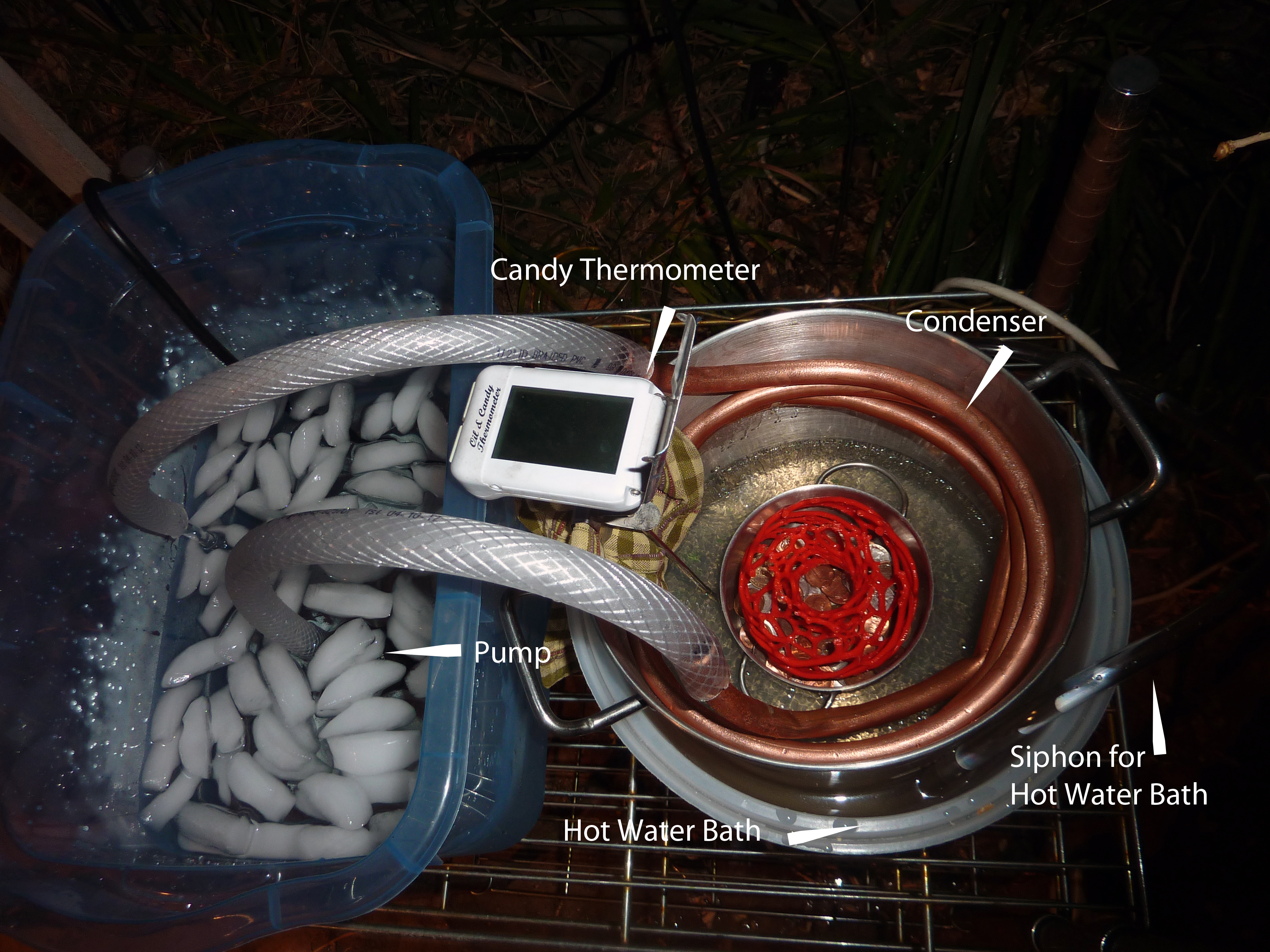

Boiling, or very hot water goes into the tupperware and surrounds the stock pot. Acetone boils at around 135F, so it is very easy to get it hot enough. I have a hose in the tupperware that I can use to siphon out the water when I when I want to refresh it with more hot water.

The condenser coil creates a zone of cool air at the top of the pot, so the acetone vapor will condense rather than escape. I got a cheap indoor fountain pump and hooked a 1/2"ID vinyl hose to it. The hose fits over some 1/2" copper tubing which I bent into coils just large enough to grip the inside of the pot. The pump goes into a tub of ice water and pumps it through the copper coils and back into the tub through another hose.

I already had a candy thermometer around, and used it to keep track of the acetone in the stock pot. When I reached my hand in, I could definitely feel the cool air at the top, and uncomfortable heat (130F) in the small pot at the bottom.

Here is a test I did. I left it in for about a minute, which was probably a litile too long.