Topic: Da vinci Minimaker - nozzle constatly getting clogged

Hello.

I have a problem with my minimaker. The nozzle head keeps getting clogged. It clogges right away after i clean it and load the new filament.

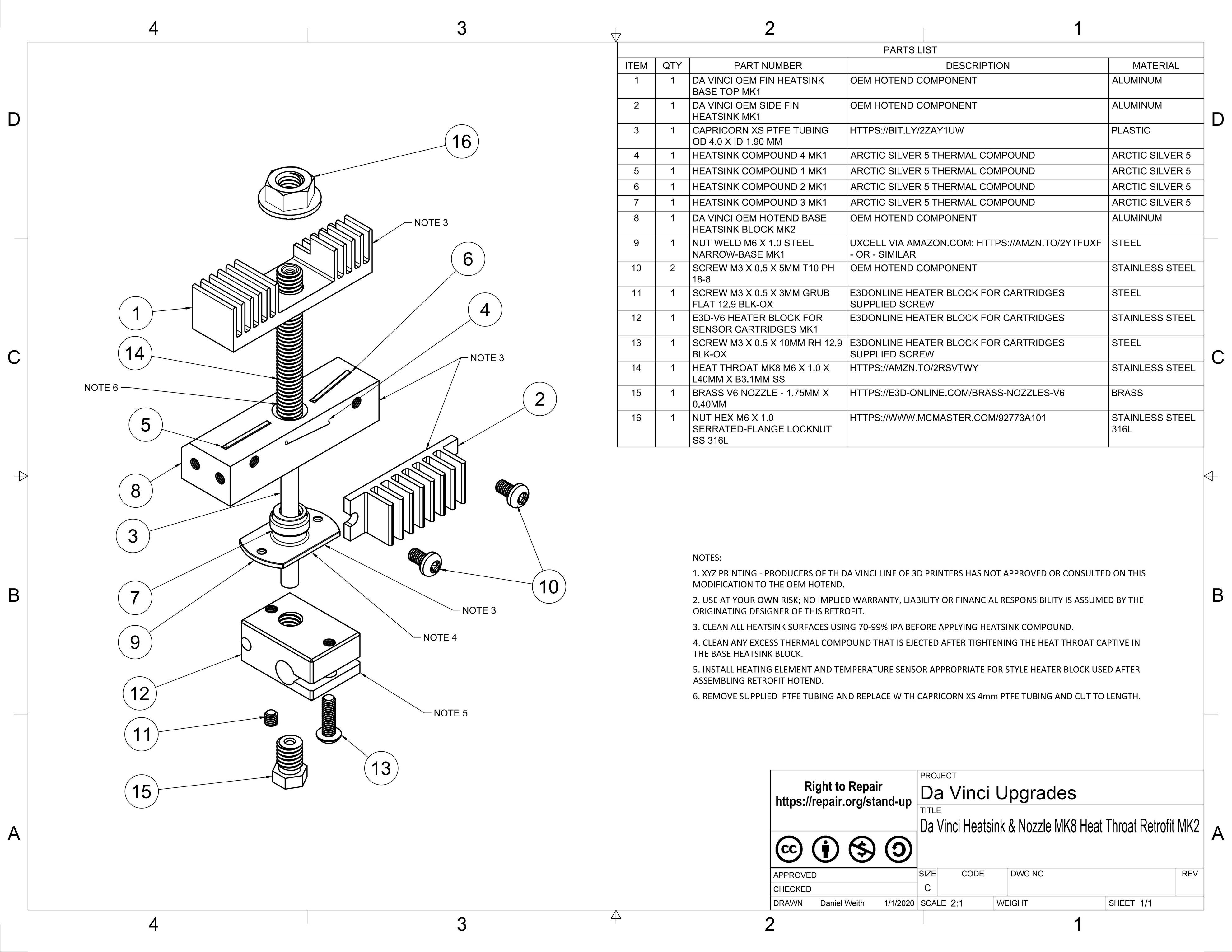

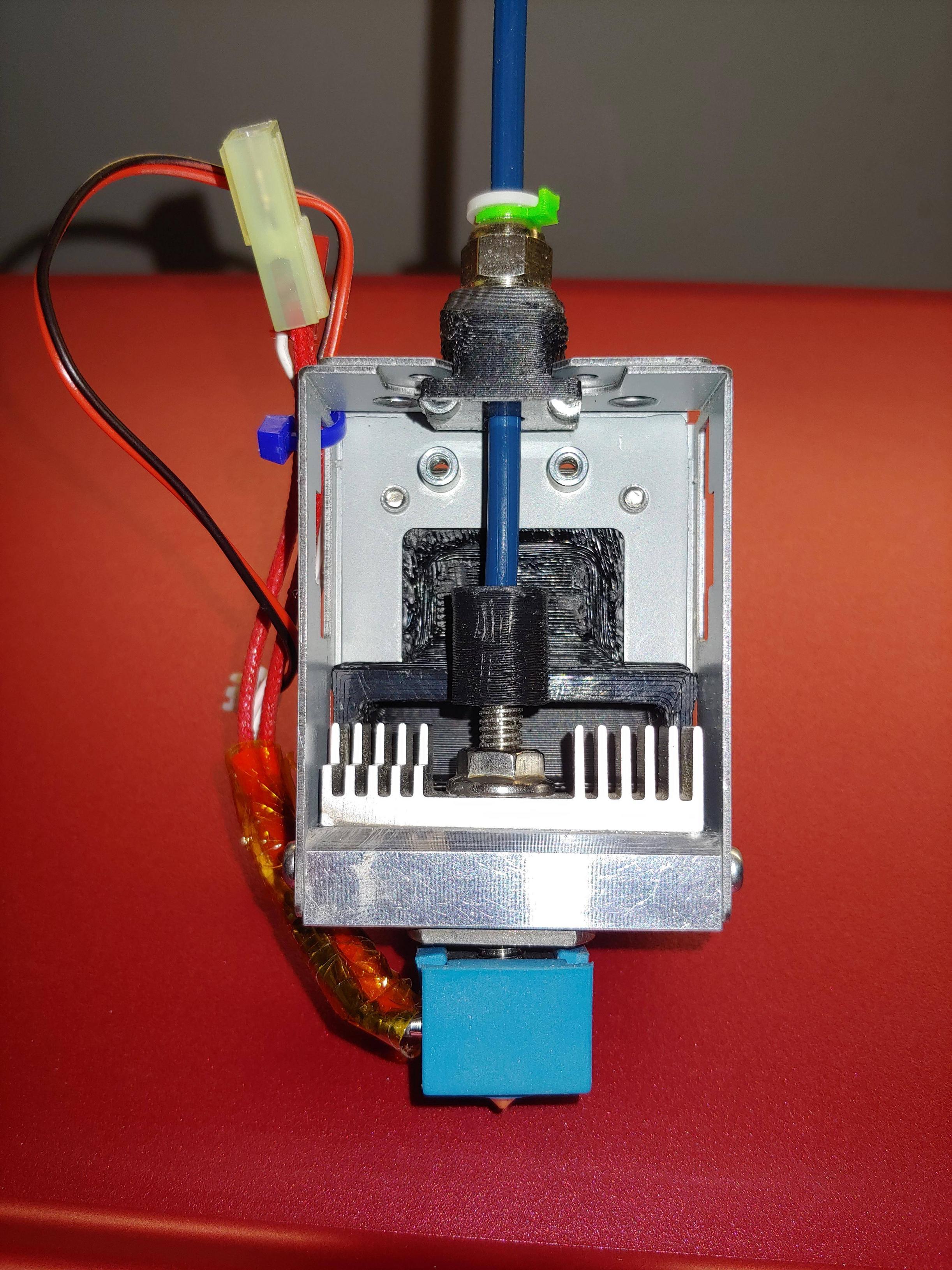

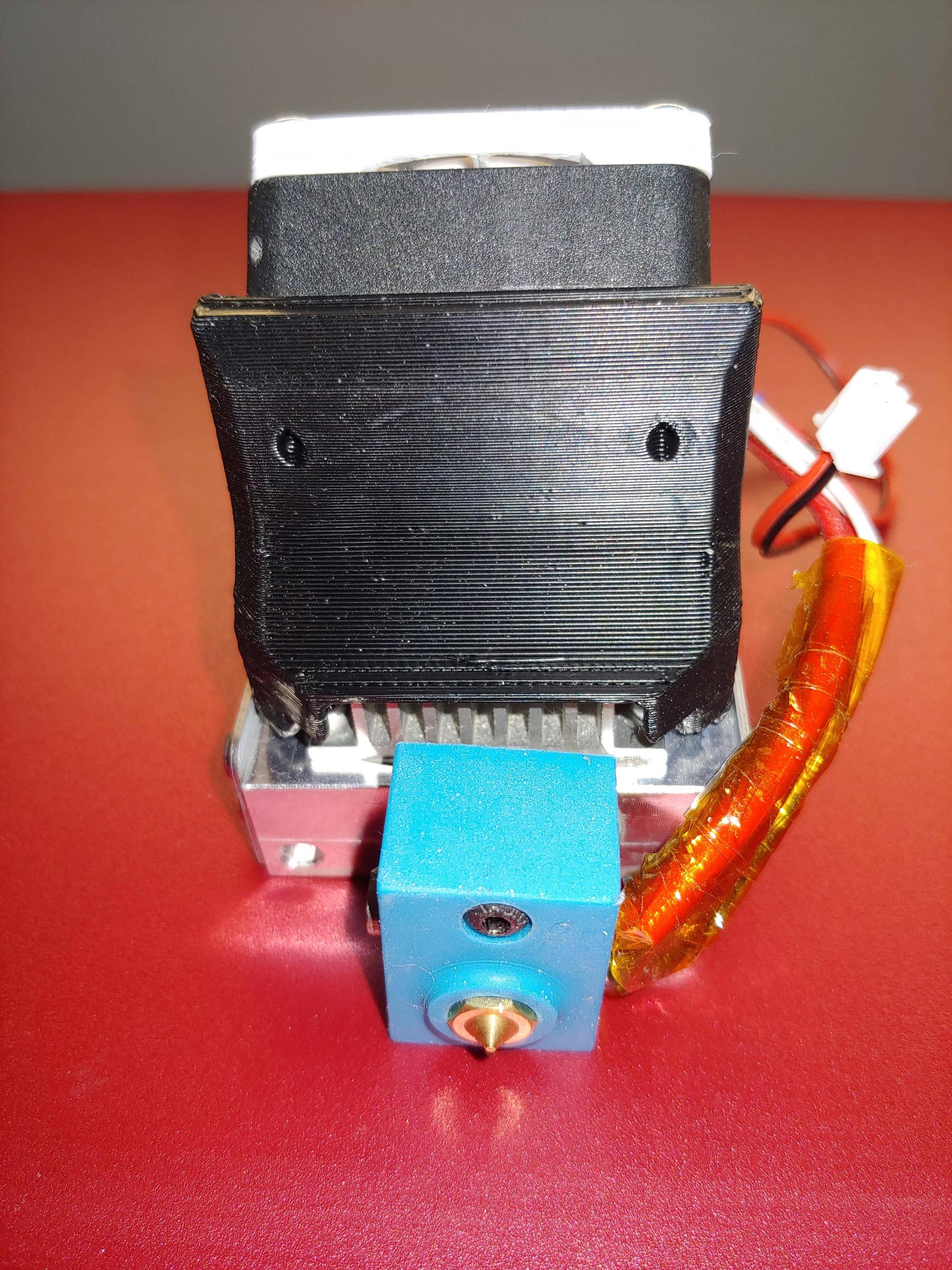

Yesterday I took the head apart. And cleaned it using hand to heat the nozzle up and cleaned it up. During cleaning i noticed that the threaded rod that holds the heatsink has a thin nylon or teflon tube in it. The closer inspection revealed that the tube was damaged on the side, probably because of cleaning? How imporant is that tube because i think that this is the reason the filament keeps getting jamed? I took the tube out it helped. The printer printed for about 2hours but then it clogged up again.

I don't know what else to do. Is it possible to replace only the nozzle? Been looking around and could only find complete extruders.

Thank you in advance

Jure