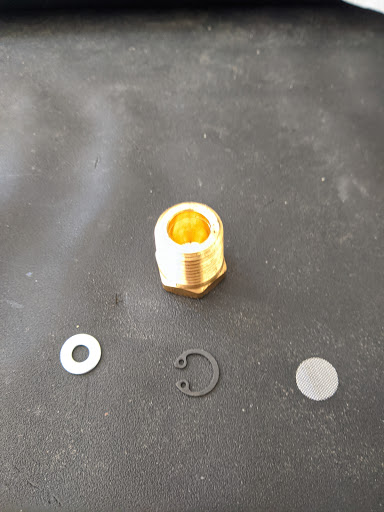

so is it a useless piece? I've spent three days trying to install the melt filter in mine. I found a youtube video where a guy hunches over his, not visible on camera, and gets it installed in about 10 seconds; I don't know what movements I'm supposed to make mechanically to achieve this.

It's probably also worth noting I'll likely regain full use of my thumb in a day or two, after losing a chunk of it to a pair of pliers while trying to fit the circlip in the nozzle. When fully compressed, the circlip is geometrically a larger circle than the nozzle itself, so I'm pretty sure installing it is physically impossible anyway.