Topic: Struggling to get the Ramps 1.4 bed thermistor to read correctly. Hel

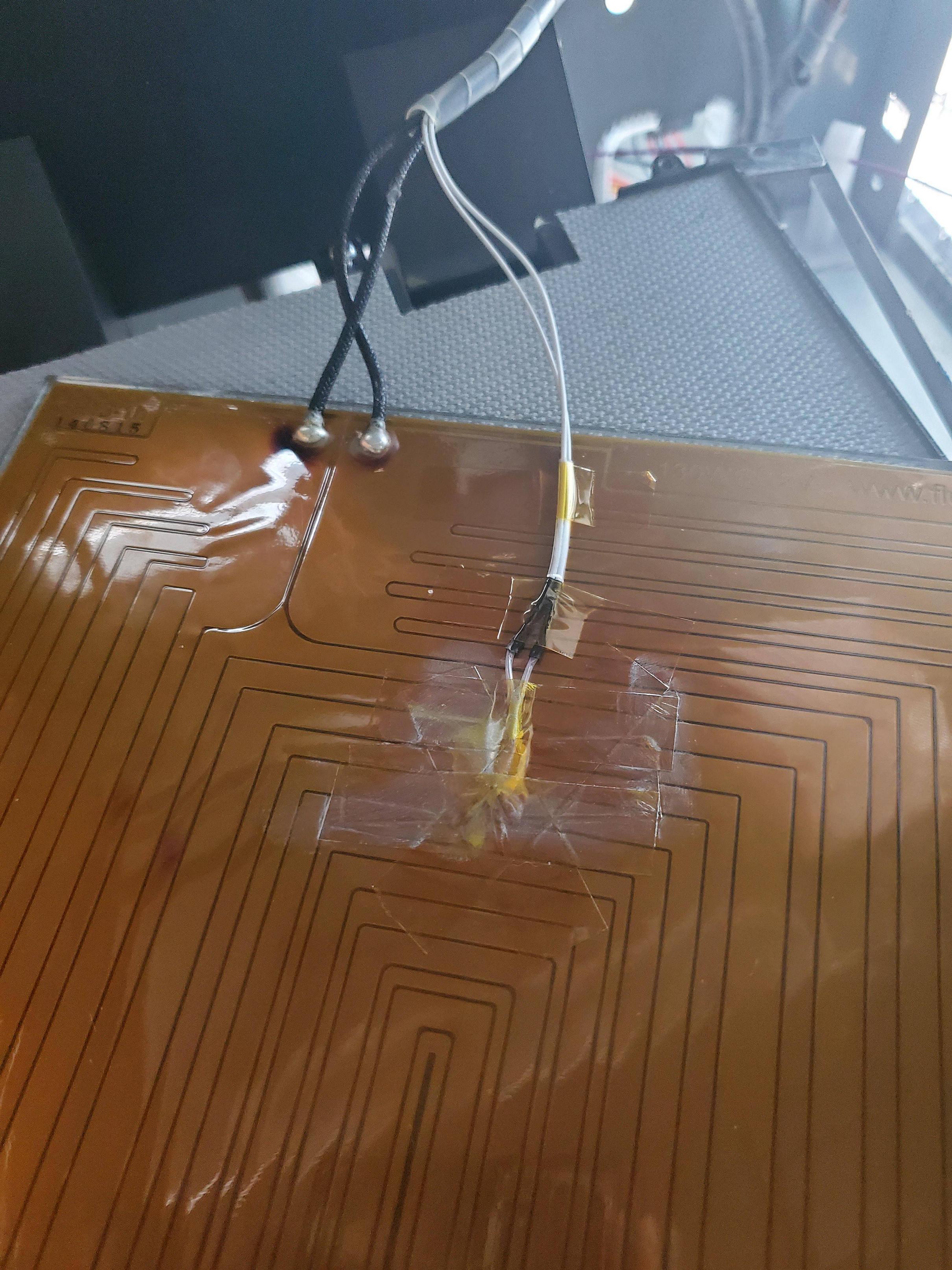

Struggling to get the bed heater temperature to read correctly on the Ramps 1.4.. I bought brand new 100k NTC 3950 thermistors on Amazon (since I used old spare ones and couldn't figure out what they were). I have it programmed in Repetier 0.92.9 correctly as "100k NTC 3950". It still shows the temperatures way way off. Like this:

60c displayed on the LCD is = 105c measured by a laser thermometer

55c displayed on the LCD is = 82c measured by a laser thermometer

50c displayed on the LCD is =65c measured by a laser thermometer

45c displayed on the LCD is = 54c measured by a laser thermometer

40c displayed on the LCD is = 46c measured by a laser thermometer

The printer originally had a ferrite core (small black magnetic clamp) which was clamped on the heater wires and the thermistor wires.

When the NEW thermistor wire is in the ferrite core with the heater wires,, the readings are insane, like 900c. When I take the wire out of the ferrite core it settles down to about 20c which is room temperature in that room. So its causing some variations in the readings for sure.

Any ideas? I'm at a loss.