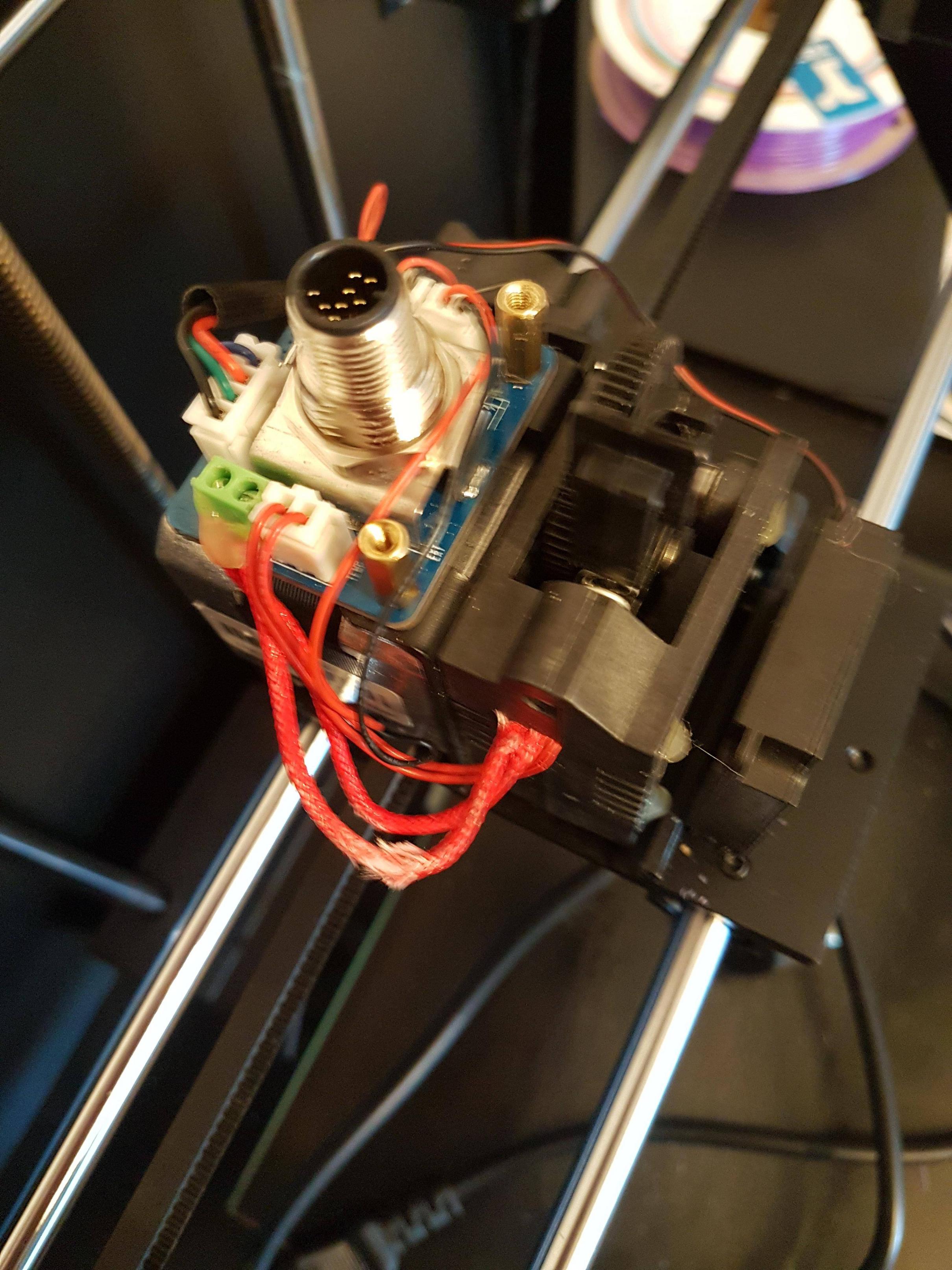

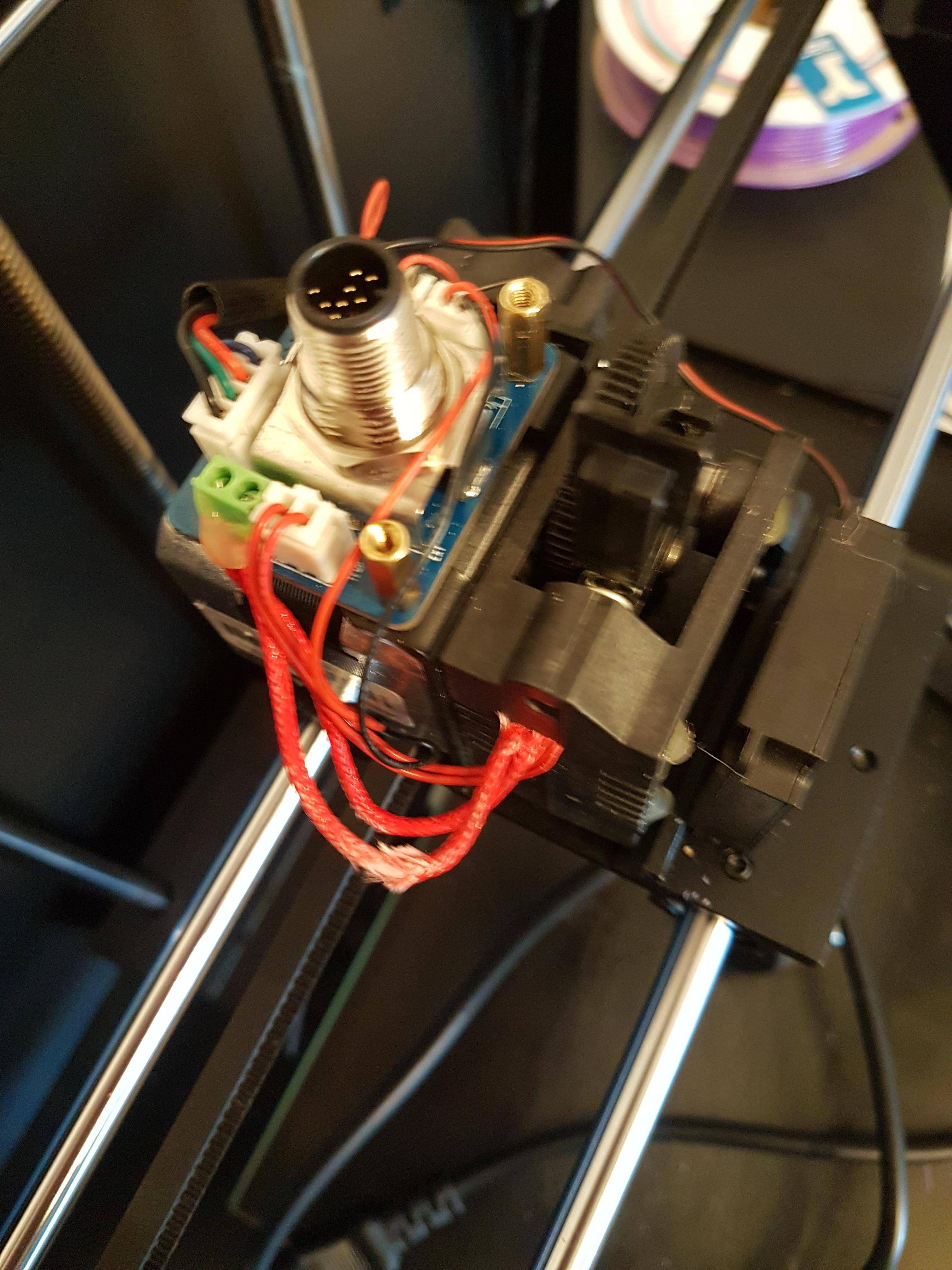

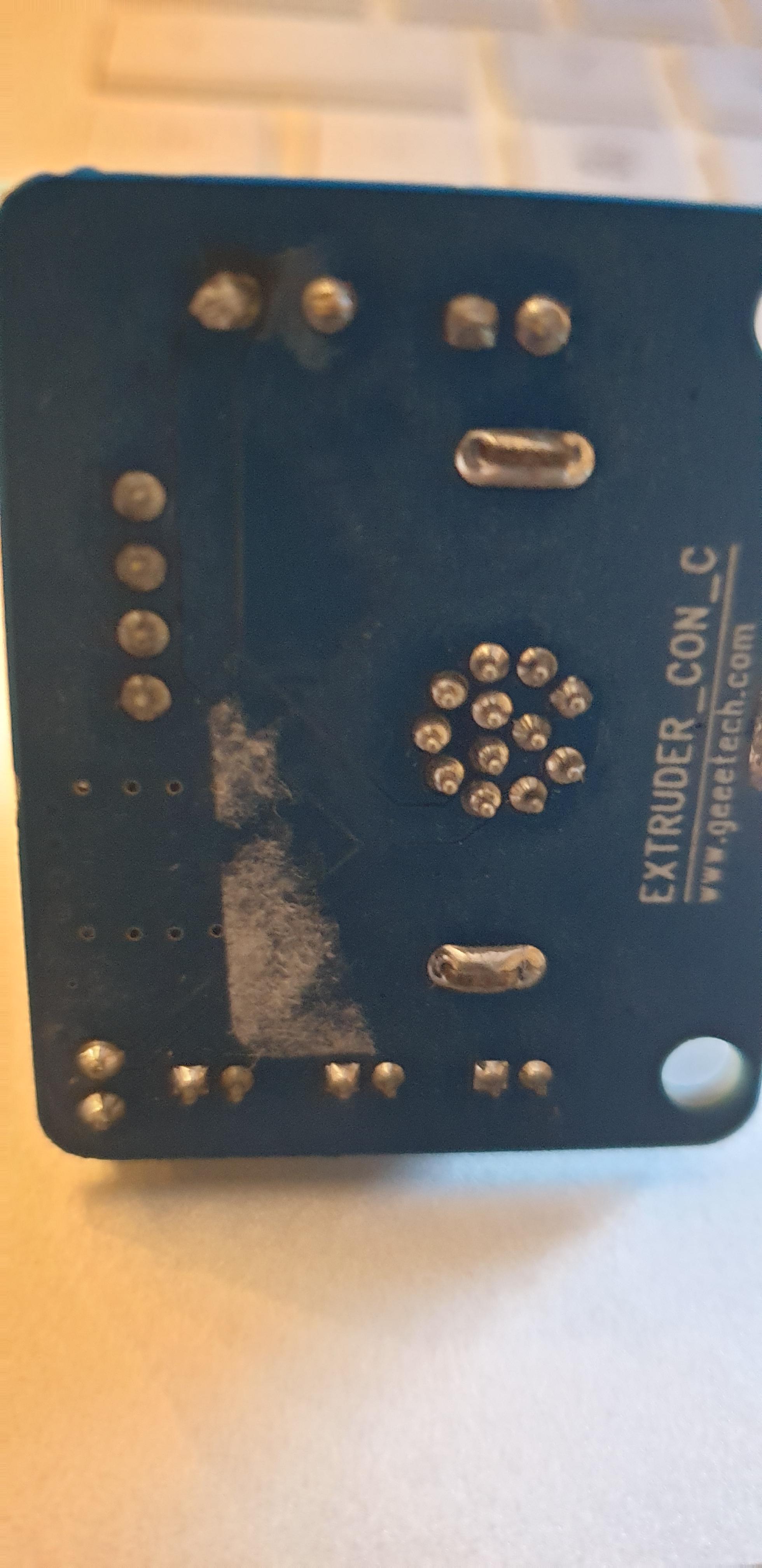

the two heavy, "waxy" wires are for the heater cartridge.

black and red wire pairs are typically fans.

the 4 multi-color wires in the one plug at the back are for the extruder motor.

the pair of smaller red only wires in the white plug next to the waxy wires are most likely the thermistor wires.

Now, with all of that information in hand..

yes, the rubbing noted on the big waxy wires is of concern, but it is not the source of your temperature reading issue. those wires operate the heater only. As long as the rubbing has not compromised the inner plastic coating, they should be fine.

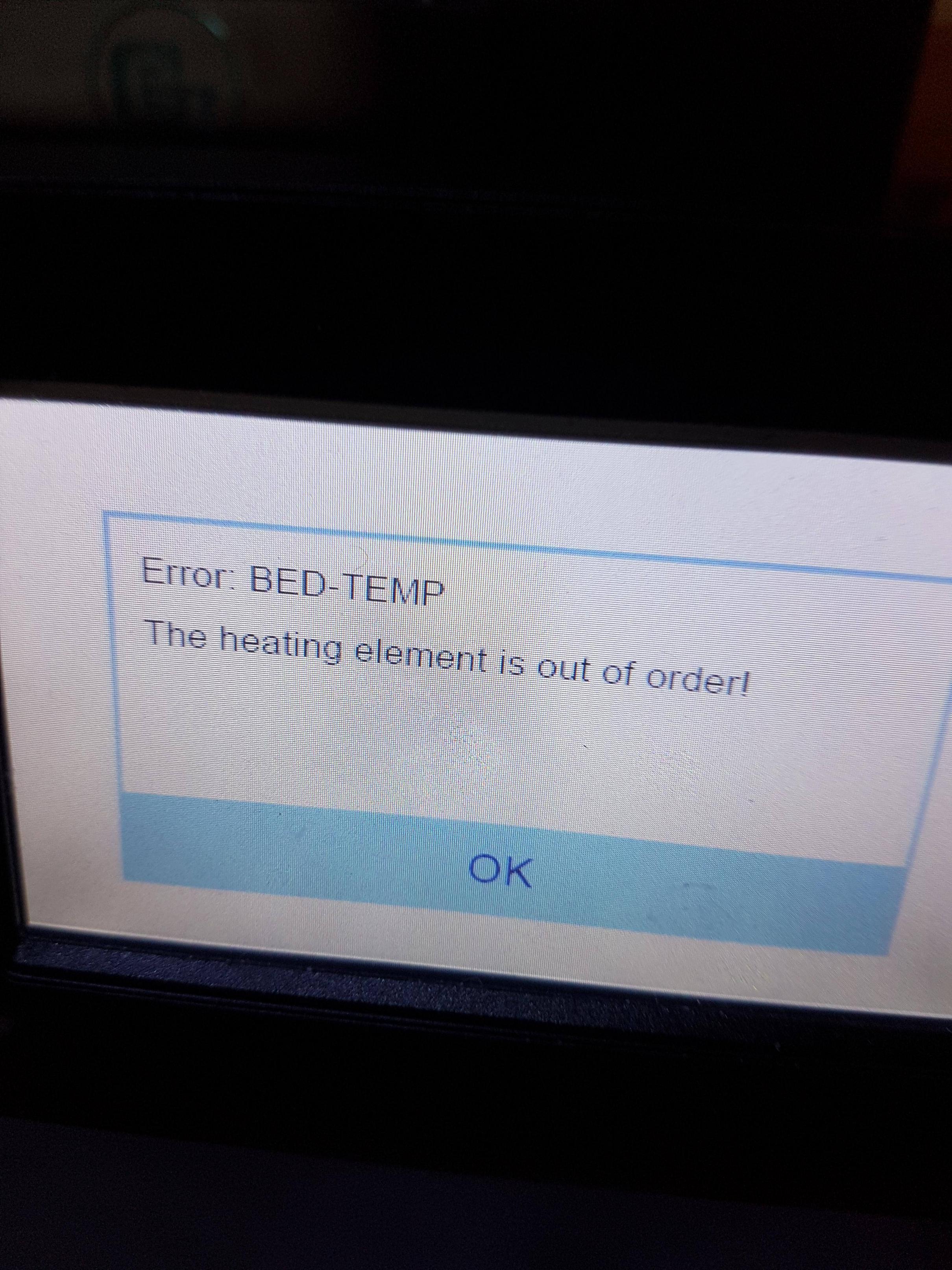

the thermistor is the problem here - meaning the two small red wires - one (or both) wires to the thermistor itself are broken or otherwise damaged somewhere along the line. This is where the problem lies. If the controller board can not get a proper reading of ambient temperature when turned on, it will not function - period. It will not take commands, it will not send power to the heaters, it will not function AT ALL until the temperature readings are restored to normal function. BOTH thermistors (hot end and heated bed, if available) must be in good operating order before the printer will function.

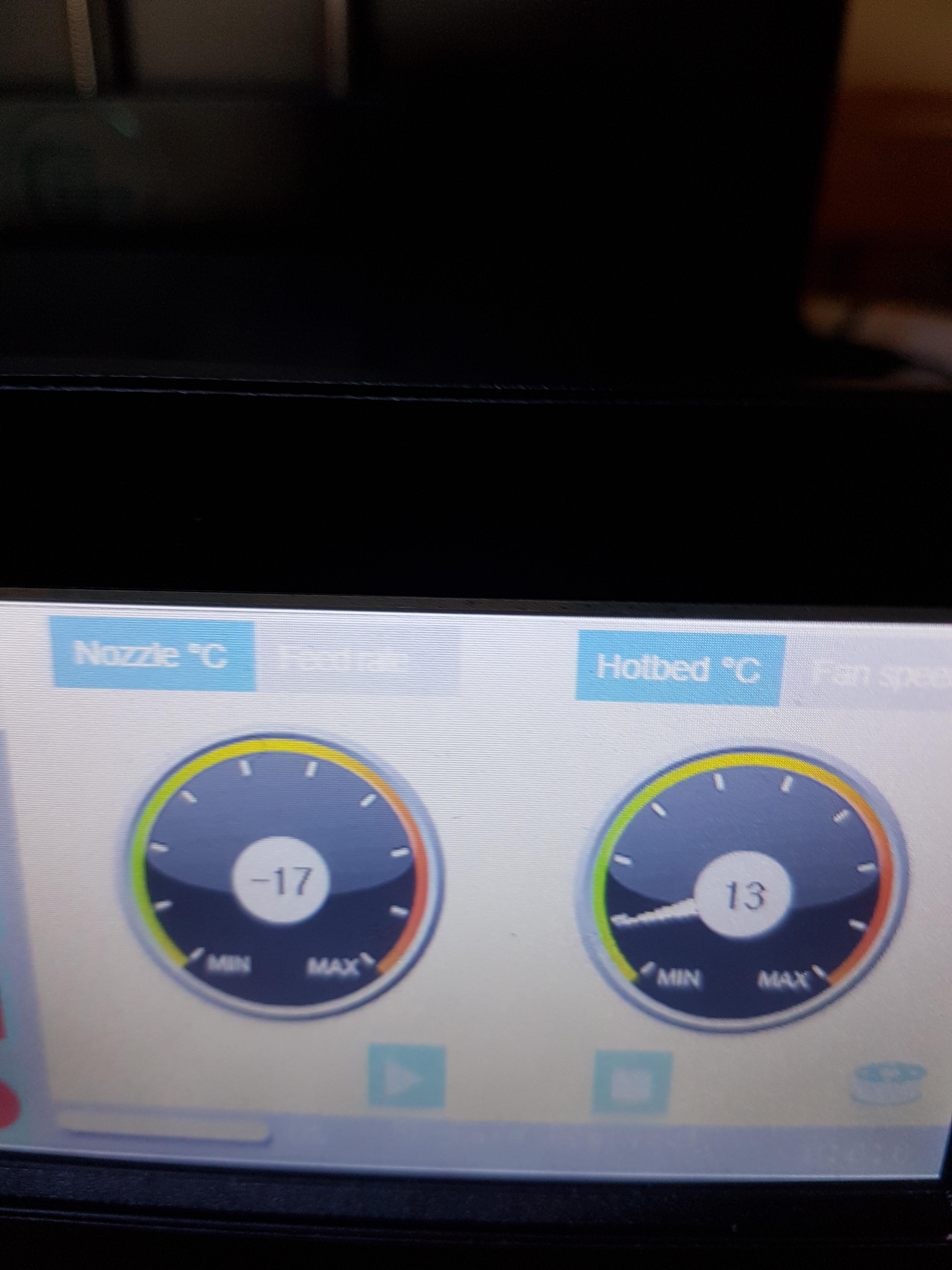

Now, why it is showing a temp error on the hotend (the -17 temp reading), but telling you the Bed is out of order is kind of weird.. but either way - the thermistor is definitely a problem. Fix the hotend thermistor and you may be able to restore function.

and for the record "not a good fit" and options that are supposed to be there, but are not (your wifi issue), are pretty typical of Geeetech. That is why most people with any real experience will not recommend any of their products.

To be perfectly honest, I am amazed they are even still in business.

SD4 #1 & #2 - Lawsy carriages, E3D v6, Rumba controller board, mirror bed plate, X motor fan, upgraded PSU & Mica bed heater

SD4 #3 - in the works ~ Folgertech FT-5, rev 1

Printit Industries Beta Tester - Horizon H1