The Repetier Firmware upgrade needs more detailed instructions for us Arduino noobs. So here is what I documented in my several attempts to get it to work, which I did after a couple evenings of digging around and failed uploads.

This is all based on the latest version of the Git Hub upgrade posting by Luc.

1. Down load the Repetier 0.92 update files from:

https://github.com/luc-github/Repetier- … -4-Davinci

Extract those files to a folder you make in your Documents folder on your C: drive. Or any folder location you can remember. You will use those files for the update, and any time you need to reflash your Da Vinci.

Download Arduino 1.8.0 from https://www.arduino.cc/en/Main/Software

You have to click on the link for older software which gets you to:

https://www.arduino.cc/en/Main/OldSoftw … s#previous

Then download 1.8.0 to your computer and it will be an .exe file. Click on that executable file and install to your Program Files folder.

Download Repeiter Host from https://www.repetier.com/

unpack and install that . It automatically includes Slic3r. So you don’t need to separately download Slic3r. I found out that a separate installation of Slic3r will cause Repetier Host to fail. So just let Repetier Host use the automatic download version.

You can Run Arduino 1.8.0 at this time, but the compiling and upload to your Da Vinci won't work, so you need to fix that by using two different files to get it to see your Da Vinci mother board. So modify your Arduino program with the following modifications

NOTE: note "Dano" is my user name on my computer. So on your computer you should see your user name in your C:\Users\.... folder.

Copy and paste the file "variants.cpp" from:

C:\Users\Dano\Downloads\Repetier-Firmware-4-Davinci-master\Repetier-Firmware-4-Davinci-master\src\ArduinoDUE\AdditionalArduinoFiles\Arduino - 1.8.0 -Due 1.6.8\Arduino15\packages\arduino\hardware\sam\1.6.8\variants\arduino_due_x

To: C:\Users\Dano\AppData\Local\Arduino15\packages\arduino\hardware\sam\1.6.12\variants\arduino_due_x

Windows will ask you if you want to replace the file, and you click yes.

NOTE: App Data is a hidden file with program settings files in it. If you don’t see it, go to your User folder in Windows Explorer. At the top, select the View Tab, then check the box for hidden items. You should then see AppData folder

OK now start Arduino 1.8.0 . You might notice that the icon has changed to a generic blank icon, not a problem.

In the Arduino menu tabs, select Tools, then Boards "arduino somethingorother". Scroll down until you see the “Arduino Native USB" type board, which should be all the away at the bottom. If that is not selectable (not there), scroll up and select “Board Manager” at the very top of the list of boards. You'll get a new window, which paragraphs of board listings. You have to read the listings and find the type that supports "Arduino DUE". Click on it, and an Install button should show up on the right lower edge of that paragraph. Install that (85 kB or so). Then close that window and get back to Boards (Tools-Boards). You should then be able to select Arduino Native USB down near the bottom of the list. This is the same change that is accomplished by moving the USBCore.cpp file (I think, since I didn't go that route).

Now in Arduino 1.8.0, open the Repetier.ino file which is found in

C:\Users\Dano\Downloads\Repetier-Firmware-4-Davinci-master\Repetier-Firmware-4-Davinci-master\src\ArduinoDUE\Repetier

Click on the Configuration.h tab. You will see a big long set of code.

Right near the top, in the first block of ******Edit these Settings*****

Set the first line to the right number to match your machine. 1 for a davinci 1, for a a 2 with one fan, etc…. Just like it says in the comments //........

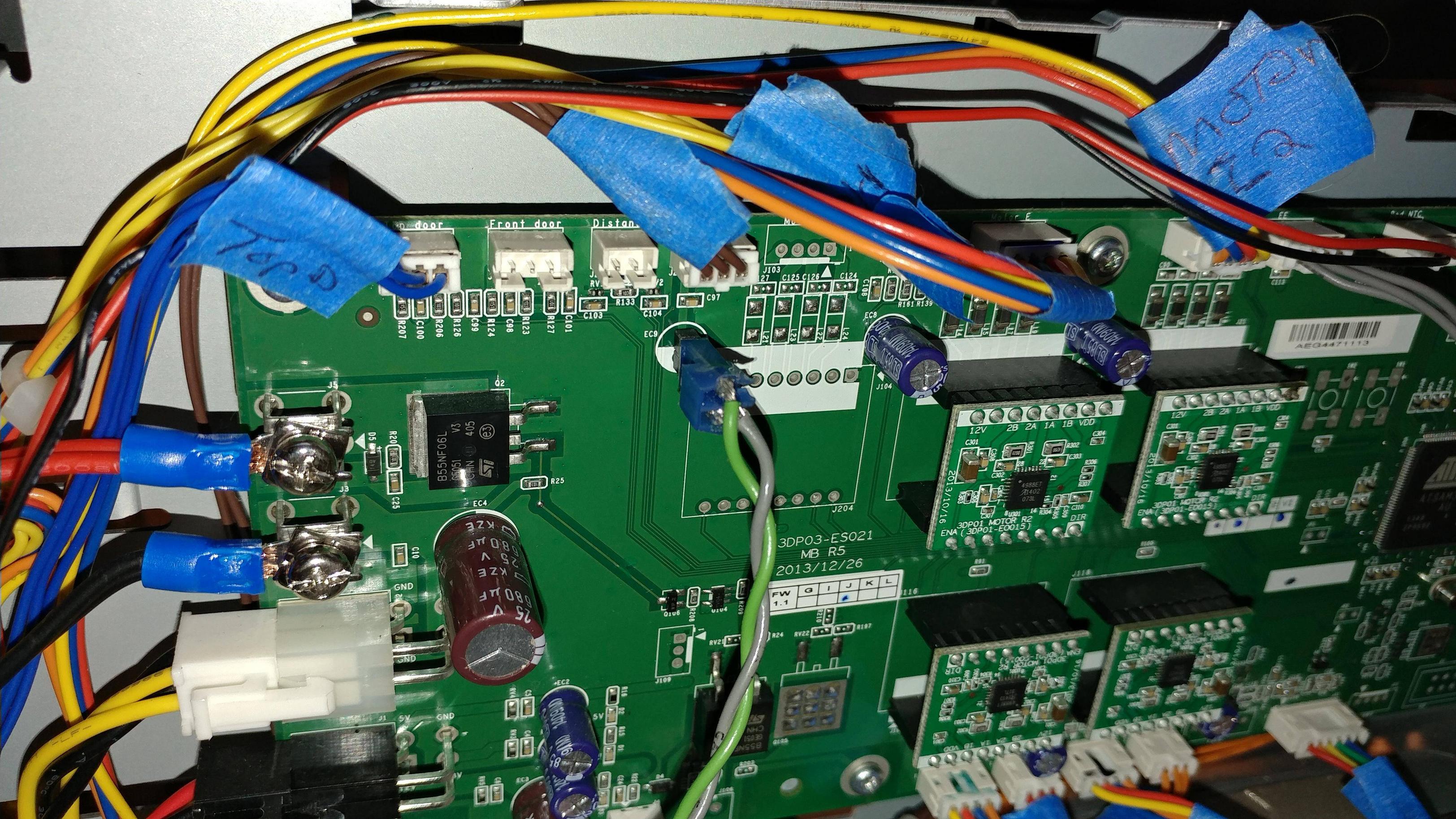

Second line is so that the firmware matches the board version, so get the right board version (this can be determined by what jumper pins you short to clearout the old firmware, J1 is the 1st version boards, and I think its J37 for the 2nd generation boards. (Look around in the upgrade postings for more info on board version).

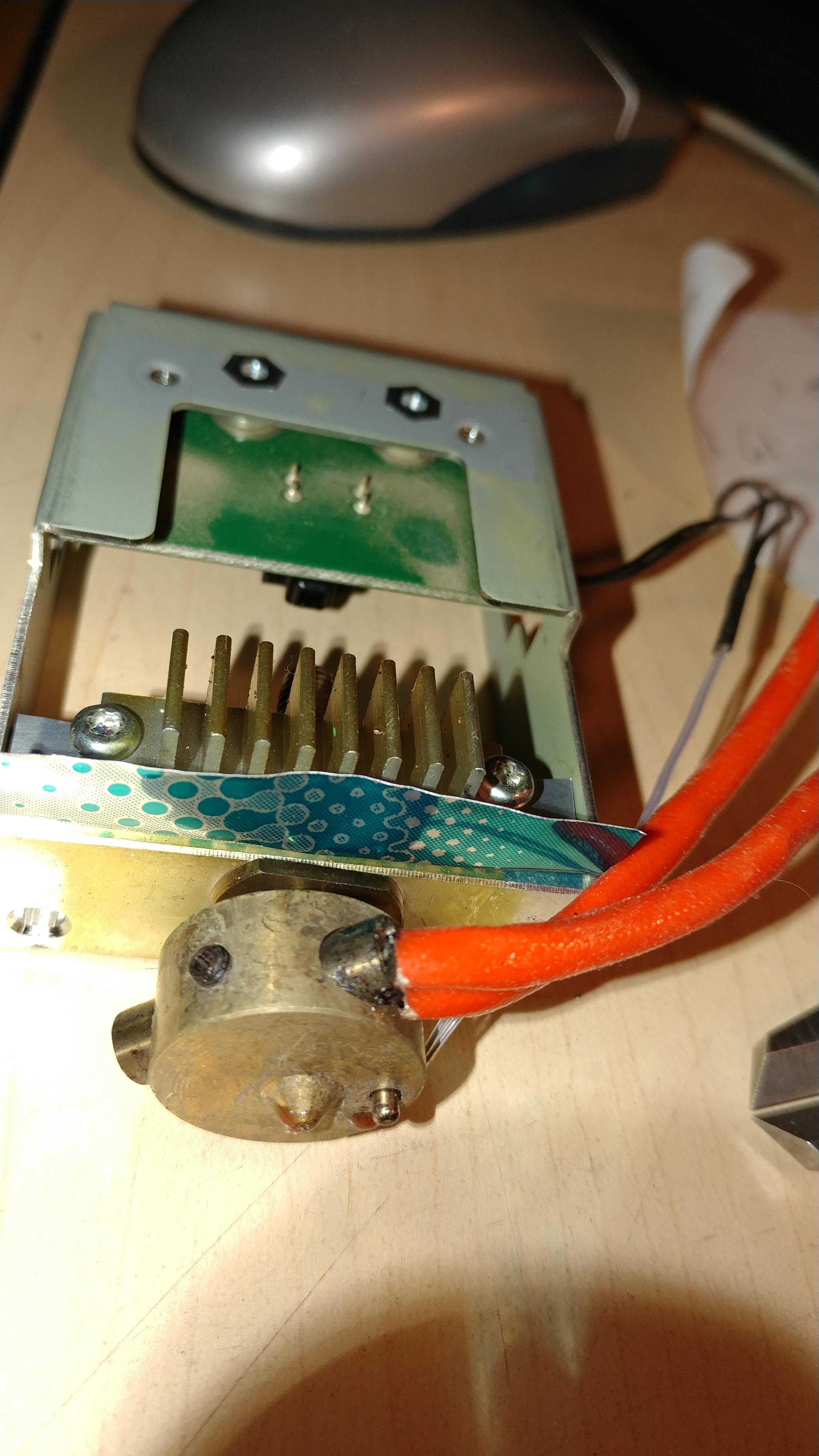

Third line is modified if you add a filament cooling fan and wire your original fan to a 5vdc power source from the board so it is on all the time. (that's another mod to do).

#define DAVINCI 1// "0" if not DAVINCI, "1" For DAVINCI 1.0, "2" For DAVINCI 2.0 with 1 FAN, "3" For DAVINCI 2.0 with 2 FAN, 4 for AiO (WITH NO SCANNER SUPPORT)

#define MODEL 0//"0" for first generation (jumper JP1 to reset ) , "1" for new generation (jumper J37 to reset)

#define REPURPOSE_FAN_TO_COOL_EXTRUSIONS 1 //Setting this to 1 will repurpose the main Extruder cooling fan to be controlled VIA M106/M107

//Warning: for DaVinci 1.0 need to add a permanent fan with power supply to cool extruder

NOTE: if you don't have a new plastic cooling fan right now, just leave REPURPOSE_FAN_TO_COOL_EXTRUSIONS 0, set to zero. You can always re-open Arduino in the future, change that after you have upgraded the fans, recomplie and re-flash your motherboard. You'll do something similar for the heated bed.

NEXT: if DON't upgrade the heated bed, You don't have to change the thermistor settings. So you can skip this next section and get to compiling and uploading.

If you change out the heated bed as I did AND use the thermistor in the heated bed, you need to make these changes (read the heated bed post below).

Scroll down to the 2nextruder section and look for the thermistor definition listings:

// What type of sensor is used?

// 1 is 100k thermistor (Epcos B57560G0107F000 - RepRap-Fab.org and many other)

// 2 is 200k thermistor

// 3 is mendel-parts thermistor (EPCOS G550)

// 4 is 10k thermistor

// 8 is ATC Semitec 104GT-2

// 13 is PT100 for E3D/Ultimaker

// 5 is userdefined thermistor table 0

// 6 is userdefined thermistor table 1

// 7 is userdefined thermistor table 2

// 12 is 100k RS thermistor 198-961

// 13 is PT100 for E3D/Ultimaker

// 14 is 100K NTC 3950

// 50 is userdefined thermistor table 0 for PTC thermistors

// 51 is userdefined thermistor table 0 for PTC thermistors

// 52 is userdefined thermistor table 0 for PTC thermistors

// 60 is AD8494, AD8495, AD8496 or AD8497 (5mV/degC and 1/4 the price of AD595 but only MSOT_08 package)

// 61 is AD8494, AD8495, AD8496 or AD8497 (5mV/degC and 1.25 Vref offset like Adafruit breakout)

// 97 Generic thermistor table 1

// 98 Generic thermistor table 2

// 99 Generic thermistor table 3

// 100 is AD595

// 101 is MAX6675

// 102 is MAX31855

Pick the Type # you will use.

Then Scroll down to the Heated Bed Section and look for:

// Select type of your heated bed. It's the same as for EXT0_TEMPSENSOR_TYPE

// set to 0 if you don't have a heated bed

#define HEATED_BED_SENSOR_TYPE 6

I used sensor type 4, its 10K and it worked (more on that in the heated bed upgrade post). So my line reads:

#define HEATED_BED_SENSOR_TYPE 4

OK, now you are ready to Verify and compile and upload.

In Arduino 1.8.0 check the COM port under tools to see that you have the right port to match where your Da Vinci is connected. if you don't the Upload will fail (and you can choose another port and try again, so not fatal).

Select the Check Mark button in the Arduino menu bar to “verify” the sketch (program). If that works, then you are ready to flash the Da Vinci.

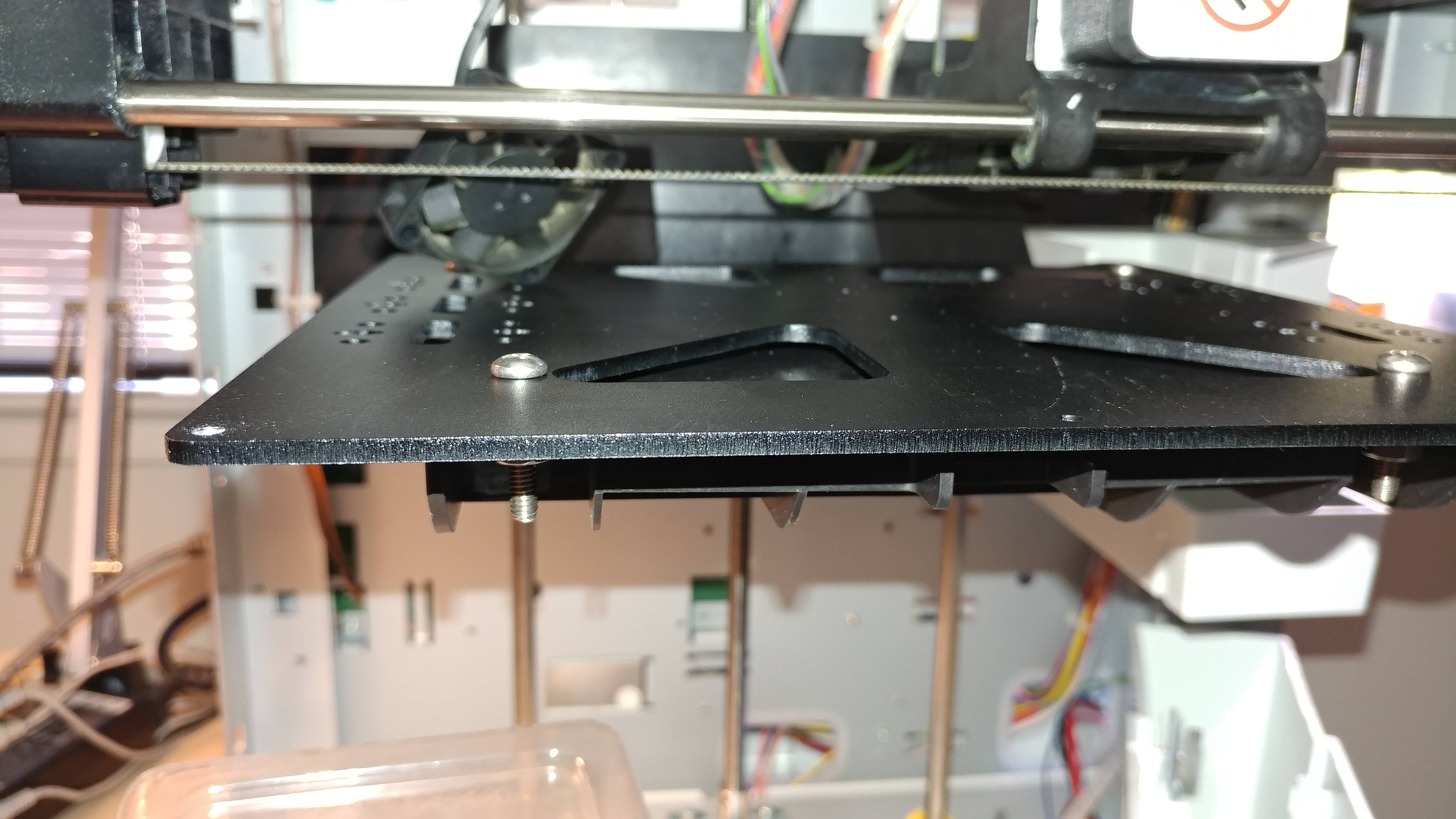

Clear the old Da vinci firmware and ready the board for the new upload by shorting the two pin holes at J1 (or J37) and turning on the power for 5 seconds. I used a metal tweezers, some used their needle nose pliers, or a piece of wire. Turn the printer OFF, then turn ON again and you should see 2 black bars in the LCD screen of the Da Vinci. Good your Da Vinci is wiped.

Back to Arduino, click on the Right Arrow button to Upload the compiled sketch to your Da Vinci. After a bit the Da Vinci should beep and the LCD screen reset with..... the extruder temp 22 / 0 and bed temp 23 /0 on the 1st line, z position on the second line, and Mul:100%Buf: 0 on the third line. If that fails, check the COM ports to see you are on the right one to the printer.

I found that if I failed the upload, sometimes the computer would fail to see the printer. If I re-did the J1 short On/off/on, the computer would again see the printer and I could try another upload.

o if you got a good upload, then press the OK button on your Da Vinci and scroll down to Settings, select it. Scroll down to Store > EEPROM and push the OK button to store, then use the home button to get back to the top screen.

And you are good.

Next start Repetier Host and connect it to the printer. On to the next post.

Dan

FFCP

Da Vinci 1.0 - Repetier 0.92!