Topic: Extruder temp falls back to room temp at start

Hello,

My old SD3 extruder has been heating up to 210 as requested, but when I hit start print, it tops out at 210 and will plummet back down to room temp over time. It is not just an indication problem as it does cool off completely. Seems like a software problem to me, but I wouldn't know what to change. Any help/advice is welcome. Thanks!

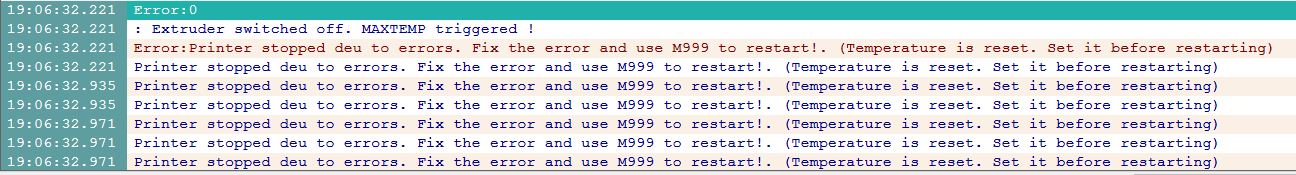

[EDIT/update] I have since discovered that the printer would cool down and refuse to print (or stop mid print) because it was throwing out a 'max temp' fault that you can see the in log screenshot below. My filament was always jamming because it was not actually hot, so it was not indicating properly obviously. Ultimately, I want to replace the thermistor and see if that is the source of the problem, BUT my temporary fix was to change the limits in the firmware from 225 to 270 and trick my machine into running 'hotter'.