Topic: Active SD3 users...Modded or Not.

Hey how many of you are still printing with a SD3?

I need working firmware. What RH are you using? Also, can you screenshot your RH printer settings, & slicer too?

You are not logged in. Please login or register.

SoliForum - 3D Printing Community → Solidoodle Discussion → Active SD3 users...Modded or Not.

Hey how many of you are still printing with a SD3?

I need working firmware. What RH are you using? Also, can you screenshot your RH printer settings, & slicer too?

im still using mine i used the firmware guide from the forum and http://www.soliwiki.com/Updating_Solidoodle_Firmware

i wish the firmware had mesh bed leveling in it so i could enable it though

repetier host im using is whatever is the latest from the website

How different is the firmware between SD3 and SD4?

-Kevin

Slicer profiles need made to order as the few default ones dont work for every print/material some need tweaked like maybe support, speeds etc so you have to create more. I have a couple dozen so far. same for filament profiles including using a digital caliper to check thickness of each roll used and which printer if more than 1 for flow calibration etc. as for RH versions I like a couple older versions that I can tweak more. newest works fine for most prints but I prefer more specific options for custom prints as most my prints are tiny detailed scale models not just low polly widgets.

im still using mine i used the firmware guide from the forum and http://www.soliwiki.com/Updating_Solidoodle_Firmware

i wish the firmware had mesh bed leveling in it so i could enable it though

repetier host im using is whatever is the latest from the website

right on. Im working on getting mine printing again its still being upgraded. right now i am looking for a write up on switching to 8825 drivers & setting the Vref. I have the OEM motors for now(ordering new ones from printit soon) Their [Y]direct-drive is & Hale bed is installed with a 3/16 aluminum surface. Next, on a Sang 1.3a when you remove the drivers are those three jumpers that are covered are those what control the micro-stepping?

My Vref readings on the 4988 drivers are

E- 242.4 Z- .480 Y- .515 X- .447

Hey how many of you are still printing with a SD3?

I need working firmware. What RH are you using? Also, can you screenshot your RH printer settings, & slicer too?

i run a couple of SD4s - same basic setup, different board however..

and yeah, the firmware from the wiki page is what I use, set up for the SD3/4

I run an older version of RH, but that is me.. use what works for you.

I do run Slic3r v1.2.9 from it, however.

as n2ri said - most settings are going to be primarily dependent on YOUR printer and YOUR materials. What works for me will not necessarily work for you, and vice versa.

but basics are..

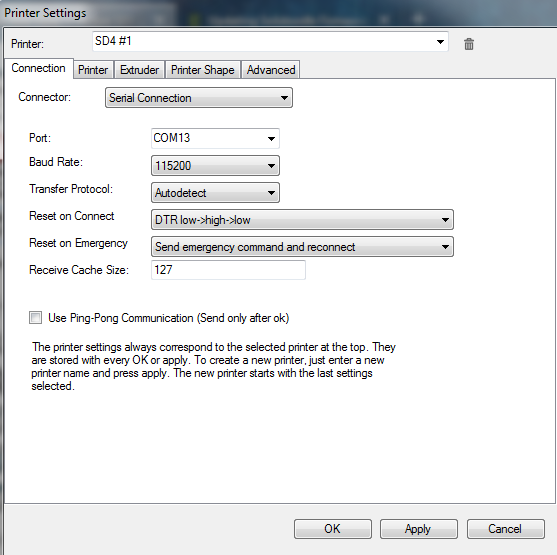

Connection: make sure your COM port setting is correct (i recommend manually changing the COM port to something higher on the PC side so that other things can not "steal" the port)

Baud Rate needs to match between PC and RH settings (and in the firmware, too)

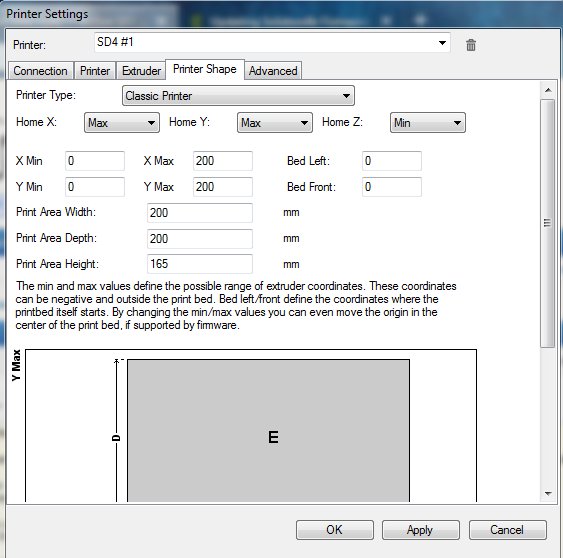

bed settings: the 3 & 4 are basically the same, so this should apply to your printer as well (however, my z height is restricted a little due to a stabilizer on the front of the bed)...

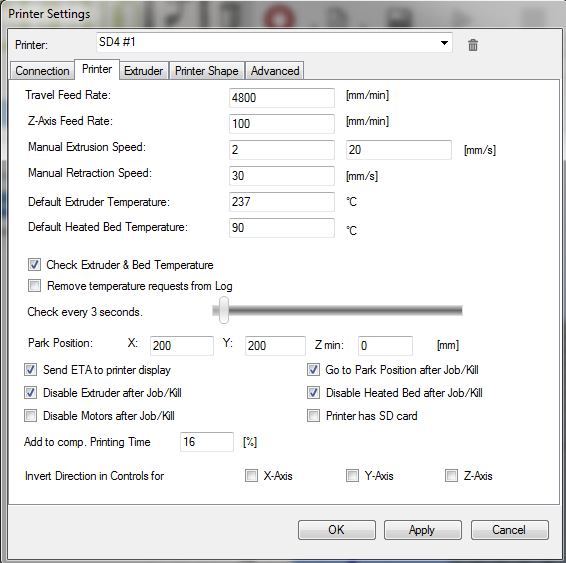

Printer Settings: this is where things really start to get different, and you will most likely need to make adjustments specific to your machine.

the default temp settings on this screen are what you want RH set to when you first start it up.. I print primarily in ABS, so my settings reflect the most commonly used temps for that. If you print primarily PLA, your settings should be adjusted for that material.

Please note: the "add to comp printing time" is a VERY specific setting to my machine and print times.. do not copy this setting!

You will need to work out what you need by tracking estimated print times vs actual print times. If you don't really care about this, then don't worry about it & leave it at its default value. This value depends a lot on print, acceleration & jerk speeds, so your machine is going to be very different than mine.

On the Sang simply replacing the drivers will double the steps. No need to change jumpers if memory serves. So you should be able to double the steps right from EEPROM and print. Of course you’ll need to dial in VREF. Make sure you use a non conducive screwdriver.

On the Sang simply replacing the drivers will double the steps. No need to change jumpers if memory serves. So you should be able to double the steps right from EEPROM and print. Of course you’ll need to dial in VREF. Make sure you use a non conducive screwdriver.

so it is okay to run all the oem motors in 1/32 step? Setting the VREF is what i currently need help with. DRV8825 StepStick Stepper Motor Drivers is what i have. They came set at 1.68-1.7.

my old VREF where E-242.4 Z-.480 Y-.514 X-.447.<---are those even close to right?

The motors are fine with 1/32 steps. VREF is less an exact voltage thing. More of a max torque thing while generating an acceptable amount of heat. Set them by ear if the motor groans it’s too high if it whines it’s too low. If the motors are getting hot then they need adjusting.

Note: probably don’t want to run Z at 1/32 stepping

SoliForum - 3D Printing Community → Solidoodle Discussion → Active SD3 users...Modded or Not.

Powered by PunBB, supported by Informer Technologies, Inc.