Topic: Support Threshold

When setting support material threshold do I bring it down from 45 degrees to decrease amount of support material used? Would 180 use support for everything? Anything happen beyond that?

You are not logged in. Please login or register.

SoliForum - 3D Printing Community → Solidoodle Discussion → Support Threshold

When setting support material threshold do I bring it down from 45 degrees to decrease amount of support material used? Would 180 use support for everything? Anything happen beyond that?

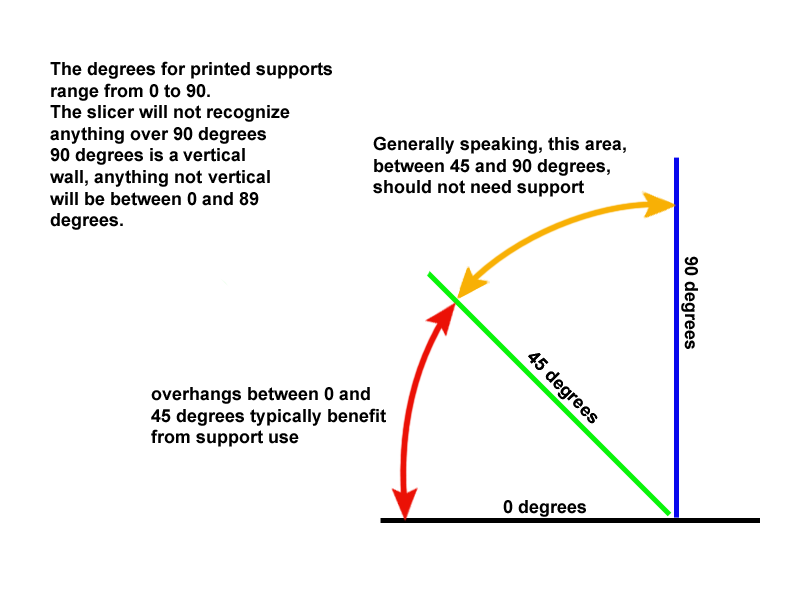

The threshold is most horizontal slope measured from the horizontal plane that can be printed without support material . Vertical is 90 degrees. 0 is the default setting for auto detection

The threshold is most horizontal slope measured from the horizontal plane that can be printed without support material . Vertical is 90 degrees. 0 is the default setting for auto detection

I forgot how angles in a 360 circle work. So like 30 would give you more support?

Tin Falcon wrote:The threshold is most horizontal slope measured from the horizontal plane that can be printed without support material . Vertical is 90 degrees. 0 is the default setting for auto detection

I forgot how angles in a 360 circle work. So like 30 would give you more support?

You get no support unless the angle is equal to or greater than the set value. There is no more or less.

Rocketman wrote:Tin Falcon wrote:The threshold is most horizontal slope measured from the horizontal plane that can be printed without support material . Vertical is 90 degrees. 0 is the default setting for auto detection

I forgot how angles in a 360 circle work. So like 30 would give you more support?

You get no support unless the angle is equal to or greater than the set value. There is no more or less.

45 degrees was the default value. Support was simply unchecked.

45 is max workable/build-able angle of SD printer without support is why, as it normally can do angles more vertical than that unless very thin single perimeter walls.

you will also learn how to adjust support thickness and angles for easiest removal for some models with practice as your skills advance.

I also bought the higher priced plastic sprue removal tool at Hobby shop made by Zurcon its near $30 but worth every penny and DONT use it for metal, wire etc as it can ruin its ability to cut clean.

oh 1 more important thing in support settings if printing something with legs etc E.G. vehicles standing on wheels. you need to find how many layers it is to main body/bottom of elevated object and set the forced support at least that many layers or it wont have support to build on when it gets up to that point and model print WILL fail. like my N scale cars/trucks need 12-32 layers for this. and you need to learn how to save multiple settings as a new short file name and make a note pad of what each "profile" settings are that you changed & what objects you use the profile for. do not write over default profiles that way you still have them if needed later. I have like 3 dozen different Profiles for mine and you need to find the folder your slicer used keeps those profiles and save a copy in backup drive so you can transfer them if needed when you change or upgrade computer, slicer, etc. as you spent lots of time/material tweaking them and would be a bit POd if they went poof. ;^).

wish somebody/anybody even instructions had ever told me this before hand, and maybe I would still have some hair and my right lower middle tooth I knocked loose banging my head hehe

Ok, visualization time.. Slicing programs do not use the full 360 degrees of a circle, or even the 180 degrees of a half circle.

They use from zero (horizontal) to 90 (vertical)

to get supports you tell the slicing program the maximum angle you need supported.

Examples...

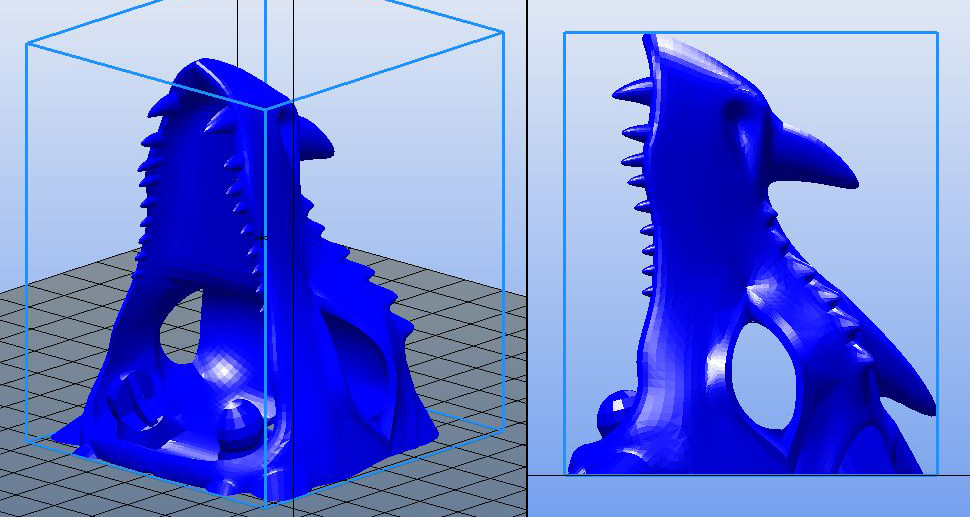

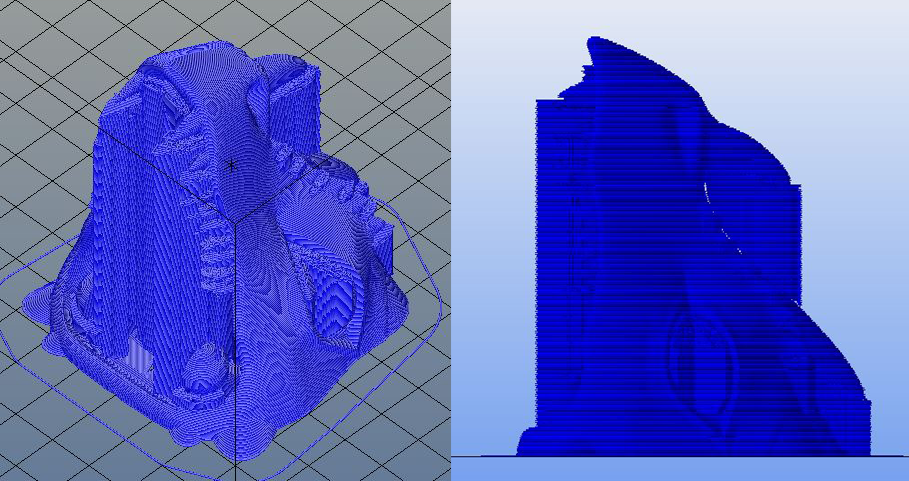

Item to be printed.. This dragon head has a lot of things going on..

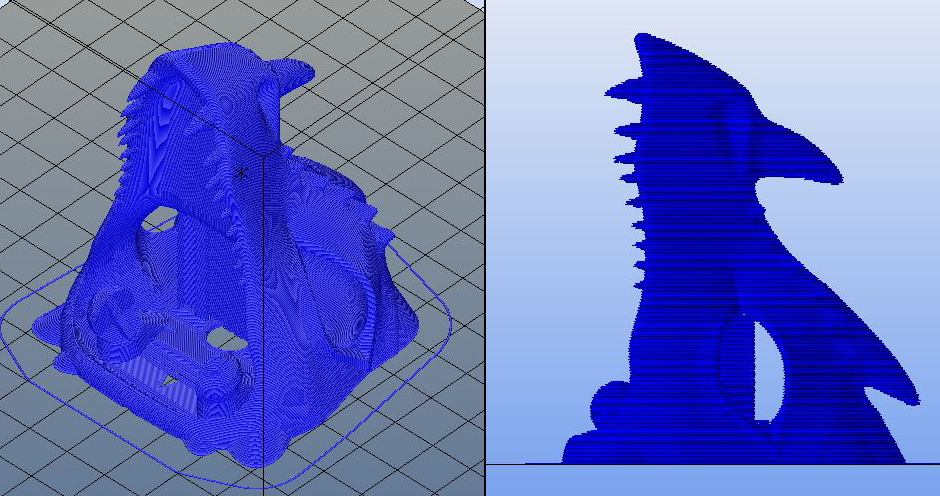

this is with supports turned on but only set at 15 degrees...it only put supports inside the mouth

this is with supports set at 45 degrees.. notice the one horn still has no supports.. this is not enough.

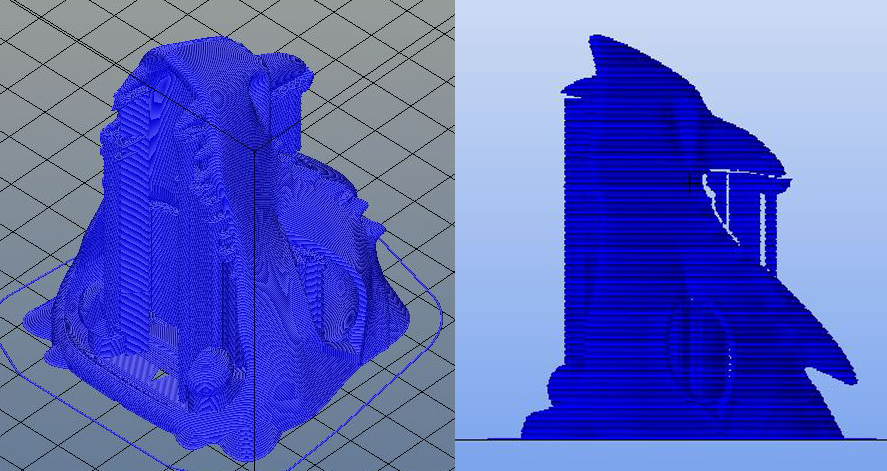

and finally here it is with supports set at 70 degrees...

all protrusions now have supports.. this is about where I had things set when I actually printed the piece.

the head was printed in 2 parts.. the other part was oriented in a way that required no support at all.

45 is max workable/build-able angle of SD printer without support is why, as it normally can do angles more vertical than that unless very thin single perimeter walls.

you will also learn how to adjust support thickness and angles for easiest removal for some models with practice as your skills advance.

I also bought the higher priced plastic sprue removal tool at Hobby shop made by Zurcon its near $30 but worth every penny and DONT use it for metal, wire etc as it can ruin its ability to cut clean...

You are most methodical in a good way. I wish the support issue was simpler so I can focus more like 80% on design.

n2ri wrote:45 is max workable/build-able angle of SD printer without support is why, as it normally can do angles more vertical than that unless very thin single perimeter walls.

you will also learn how to adjust support thickness and angles for easiest removal for some models with practice as your skills advance.

I also bought the higher priced plastic sprue removal tool at Hobby shop made by Zurcon its near $30 but worth every penny and DONT use it for metal, wire etc as it can ruin its ability to cut clean...You are most methodical in a good way. I wish the support issue was simpler so I can focus more like 80% on design.

The support issue is simple. You are just over thinking it.

If it is set to 45 then any angle greater than 45 will have supports added. Any angle less than 45 will not have supports added. The number does not control the amount of supports. It simply controls at what point they are used.

If you set it at 20 degrees it would still use the same amount of supports but only on angles greater than 20 degrees.

I think the setting you are looking for is support density. That is the setting that controls the amount of support that will be added under the set angle.

Rocketman wrote:n2ri wrote:45 is max workable/build-able angle of SD printer without support is why, as it normally can do angles more vertical than that unless very thin single perimeter walls.

you will also learn how to adjust support thickness and angles for easiest removal for some models with practice as your skills advance.

I also bought the higher priced plastic sprue removal tool at Hobby shop made by Zurcon its near $30 but worth every penny and DONT use it for metal, wire etc as it can ruin its ability to cut clean...You are most methodical in a good way. I wish the support issue was simpler so I can focus more like 80% on design.

The support issue is simple. You are just over thinking it.

If it is set to 45 then any angle greater than 45 will have supports added. Any angle less than 45 will not have supports added. The number does not control the amount of supports. It simply controls at what point they are used.

If you set it at 20 degrees it would still use the same amount of supports but only on angles greater than 20 degrees.

I think the setting you are looking for is support density. That is the setting that controls the amount of support that will be added under the set angle.

I will focus on that. With detailed statues breaking support away cleanly without punching a hole in my hand is crucial.

Is there a special way to print a hollowed sphere with support underneath it, but not inside?

Is there a special way to print a hollowed sphere with support underneath it, but not inside?

You would need a slicer that allows you to place supports manually. Such as Simplify3D which is not free. I think Craftware allows manual placement and it is free.

netfabb pro is free if you sign up under an educational or hobbyist license. It also allows you to manually place support

MeshMixer will also allow you to make manual supports and it is free

MeshMixer will also allow you to make manual supports and it is free

I have meshmixer. It can produce gcode? I assumed it was just for like sculpting shapes.

heartless wrote:MeshMixer will also allow you to make manual supports and it is free

I have meshmixer. It can produce gcode? I assumed it was just for like sculpting shapes.

its for reworking stl files

heartless wrote:MeshMixer will also allow you to make manual supports and it is free

I have meshmixer. It can produce gcode? I assumed it was just for like sculpting shapes.

no, Meshmixer does not produce g-code, but you can modify any stl model, add supports to it, etc, then save/export the model as an stl with your changes.

you then import the changed model to your slicing program as usual, slice it, then print it.

SoliForum - 3D Printing Community → Solidoodle Discussion → Support Threshold

Powered by PunBB, supported by Informer Technologies, Inc.