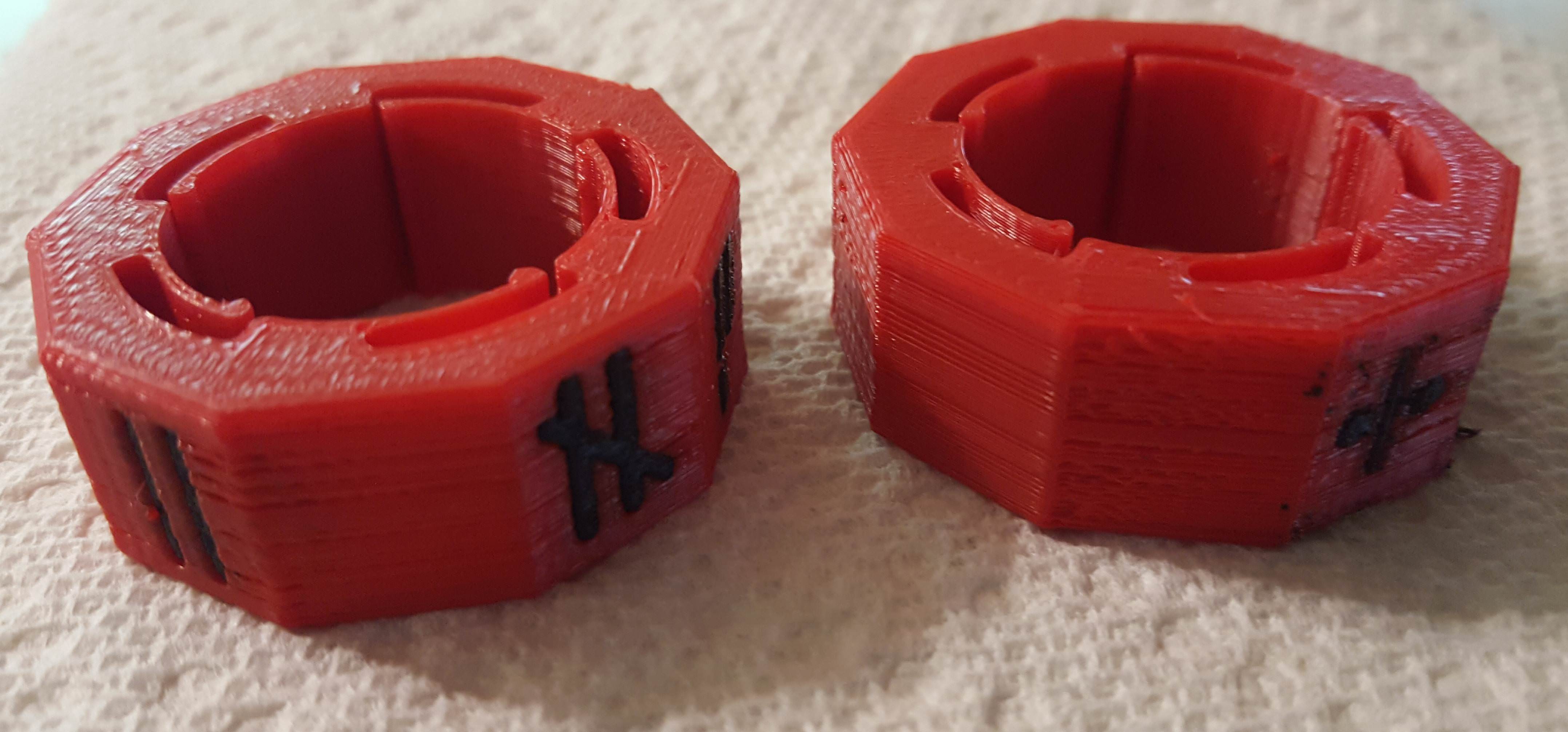

I see lots of z-band show up randomly in the picture, it can be over extrusion, but there is some random pattern that can not be explained by over extrusion. Double check with your filament spool rotation. My feeling is occasional trouble with filament feeding cause these random pattern in z-band. It might be something else, but filament spool issue is easy to check and easy to solve. you can print some ball bearing filament spool and filament guide to help reduce trouble in filament supply.

(Da Vinci 1.0, Jr. 1.0 RAMPS, miniMaker) X4, (Creality CR-10S, CR-10 mini, Ender-3) X4, Anycubic MEGA X4, Anycubic Chrion X1, ADMILAB Gantry X2 (MonoPrice Maker Select V2, Plus, Ultimate)X4--Select mini X1, Anycubic photon X4, Wanhao duplicate D7 X1.

iNSTONE Inventor Pro X2, CTC Dual X2, ANET-A8, Hictop 3DP-11, Solidoodle Press, FLSUN I3 2017X1