Topic: Davinci Jr Filament issue

I've seen some similar post but my issues are slightly different and I don't want to hijack anyone's thread.

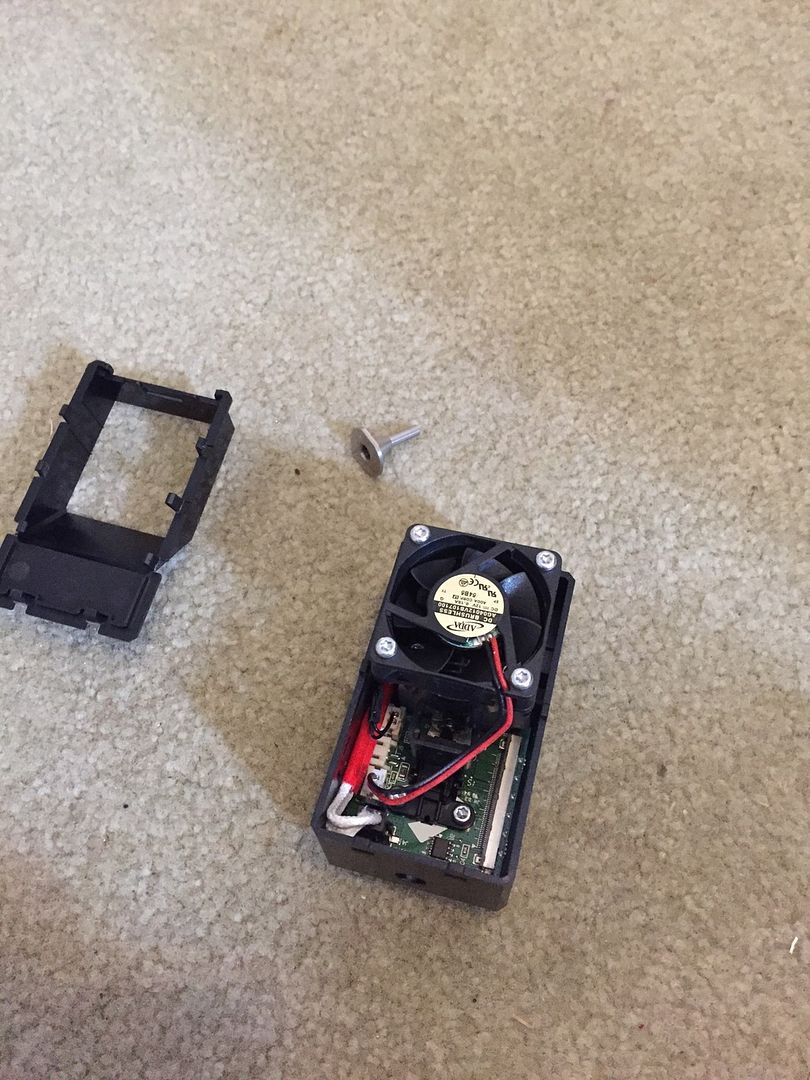

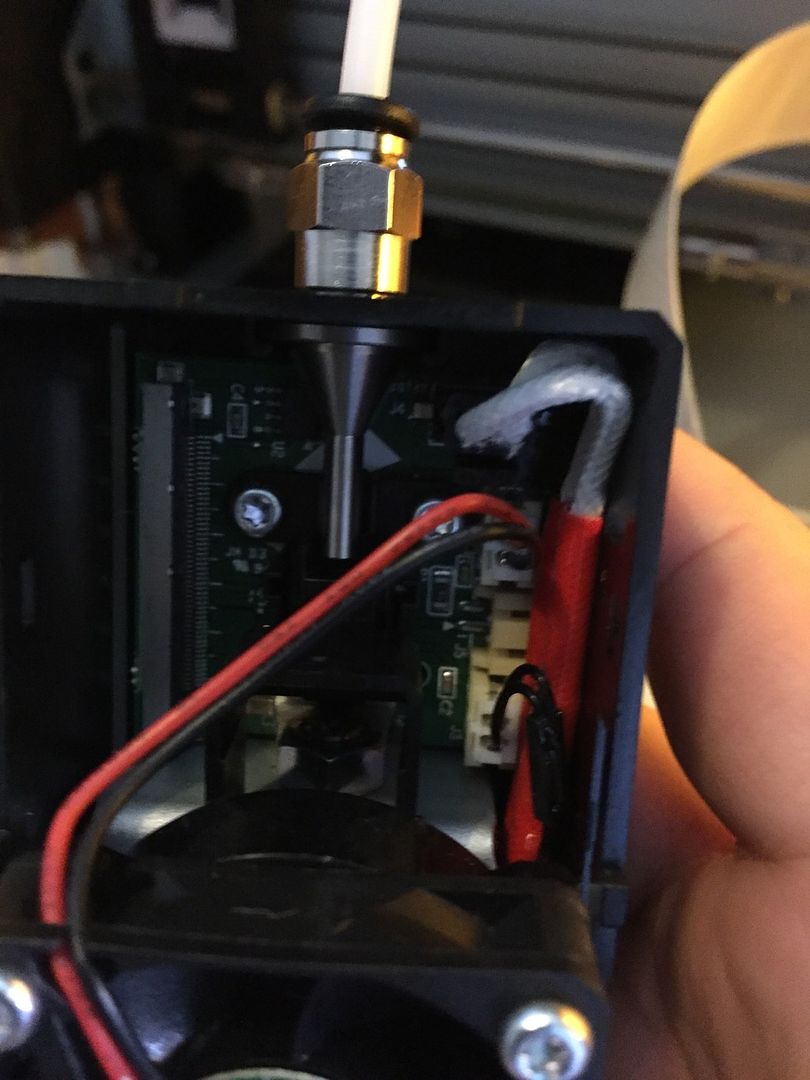

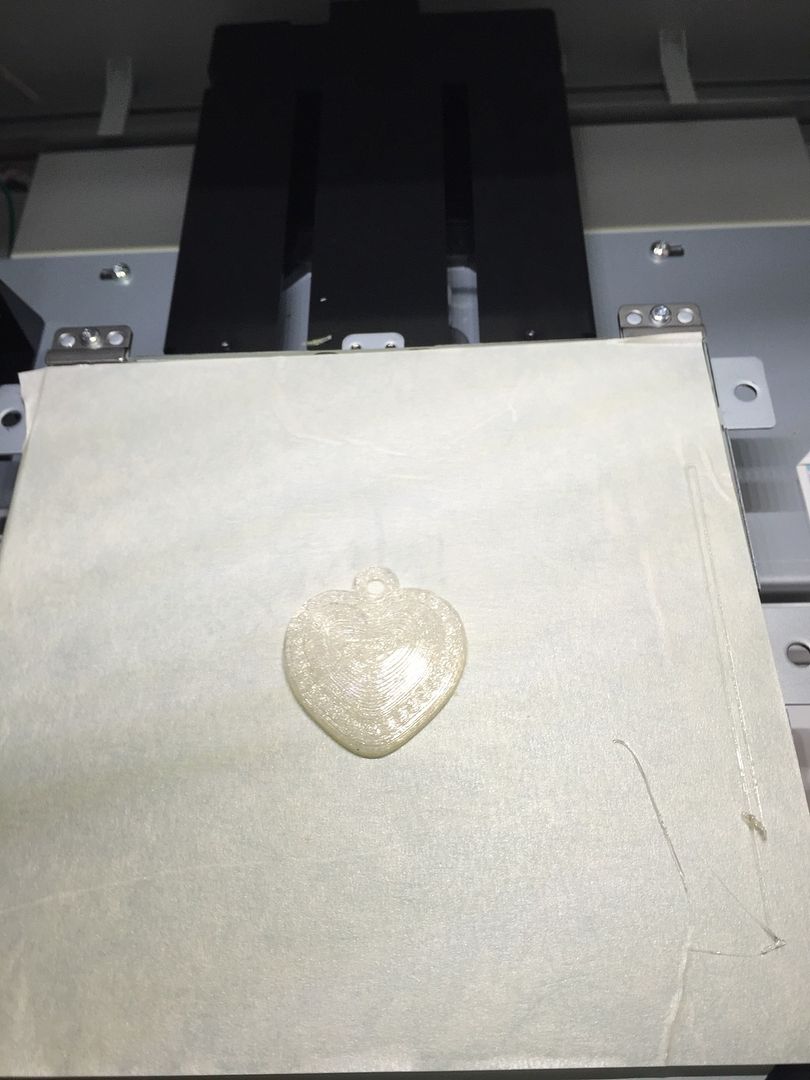

We set up our dvjr tonight. After following the tutorial process we got to the "print sample" process. The first attempt looked to be a heart shaped locket but it was not all the way printed. We tried a second attempt and it was only the outline. From that point, the filament has stopped coming out. I have tried the "load filament" option and where the first two times it streamed a string, these last few times have been nothing. My initial thoughts would be a clogged nozzle, (hard to believe as it hasn't actually printed anything yet), a temperature problem, or something with the loading. Any help is greatly appreciated.

Thanks