Topic: [PETG] EASTAR 6763 + Pellet colorant

Resin: PETG Eastar 6763 with ABS colorant pellets

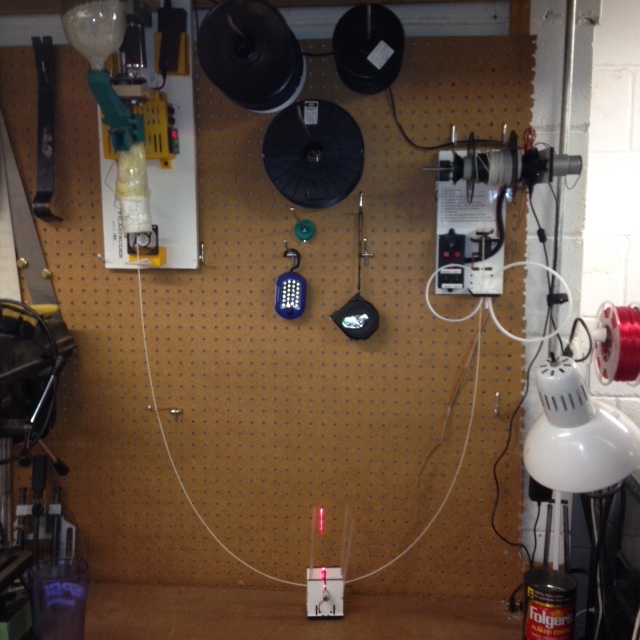

Equipment used: Filastruder #1956 ver 1.6 with 2.0 motor and 1.75mm melt filter, full barrrel insulation, vertical mount with filawinder. Beverage straws were placed over the PTFE tubing was on the laser sensor to guide the filament better. Printer is DaVinci 1.0 with custom firmware, Bowden carriage, heated glass bed, and E3D hotend.

DETAILS:

Tip Diameter: 1.6 mm

Extruded temperature: 196°C

Speed of extrusion: 8" / min

Filament diameter and tolerance: 1.60mm +/- 0.03mm

Pre-extrusion processing: Food dehydrator for 24 hours.

Extruded vs purchased: Very smooth and consistent finish on the extruded filament. On par or better than the ESun PETG filament which is the only other PETG I've used.

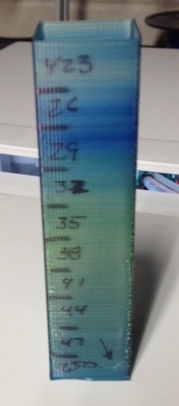

Printing: All printing was performed on an 80 degree bed with Aquanet hairspray coating. Adhesion was fine, no warping and prints easily released when cooled. The single-wall 100mm column was printed at temperatures from 250 to 223C (temp decreased 3 degrees/10mm) and .01mm layer height. Layer adhesion was excellent throughout. There was slight deformation at 250, but otherwise seemed to print fine at all these temps. I typically print ABS at 225 on my printer for comparison.

COMMENTS:

- This material was purchased from Tim at Filastruder.com. The cost was $12.99 for 4 lbs and shipping depends on total order but free if purchasing over $100. The pellets were in a blue plastic bag and shipped in a priority mail box. The pellets have no discernable scent and are evenly sized.

- Extrusion was performed at 196 degrees and resulted in consistent 1.60 mm filament at about 8 inches/minute. I have approximately 2.5 feet vertical drop in my setup. Speed varied somewhat with noticeable straining at times but should be improved with a larger nozzle size and/or higher temps. Also I noticed that when I emptied the hopper via the chute door, the speed would greatly increase to almost double. I'm sure Tim can explain the mechanics of that phenomenon but to me it appears that these pellets are really hard to shear. Since I was mainly doing this run to see how the colorant would perform with this material, I didn't spend a lot of time trying to tweak the settings for temp once I got a consistent diameter and reasonable speed.

- The extruded filament is very clear without colorant.

- I wanted to see how colorants worked with this filament and added consecutive small batches of the following:

50:1 ABS blue

50:1 ABS yellow

All colorants were from OS3dP. Color saturation was consistent. All resulting colors were somewhat translucent and blend as expected (green from blue + yellow).

- I like the somewhat banded results that occur when you use pellets vs powder, however when I want a consistent color I pelletize my filament. This was a problem with this filament. My pelletizer which works great with ABS and PLA merely chewed on the PETG, similar to results I've had with nylon. For this reason, I would not recommend using pellet colorant with this material unless you don't mind banding or have a better solution for pelletizing.

My setup

Pellets

Filament (messy spooling was my fault, not filawinder and dust was also my fault)

Print (arrow shows deformation, top number should be 223 vice 423)

Pelletizer (http://www.thingiverse.com/make:202169)

Results of trying to pelletize filament