Topic: Jr Hotend - All Metal or PTFE lined

Ladies and gents,

As some of you may know I've ordered 40w cartridge heater for my Jr to replace 25w one which unfortunately can do only 232c without the fan and 214c with the fan.

And the relay of course, I don't trust that flex cable with the current load so extra 15w will definitely fry it.

So new heater cartridge should give me more temperature out of it but... Is it all metal hotend type or PTFE lined one?

Does anyone know?! Anyone managed to cut theirs in half to see what's inside?

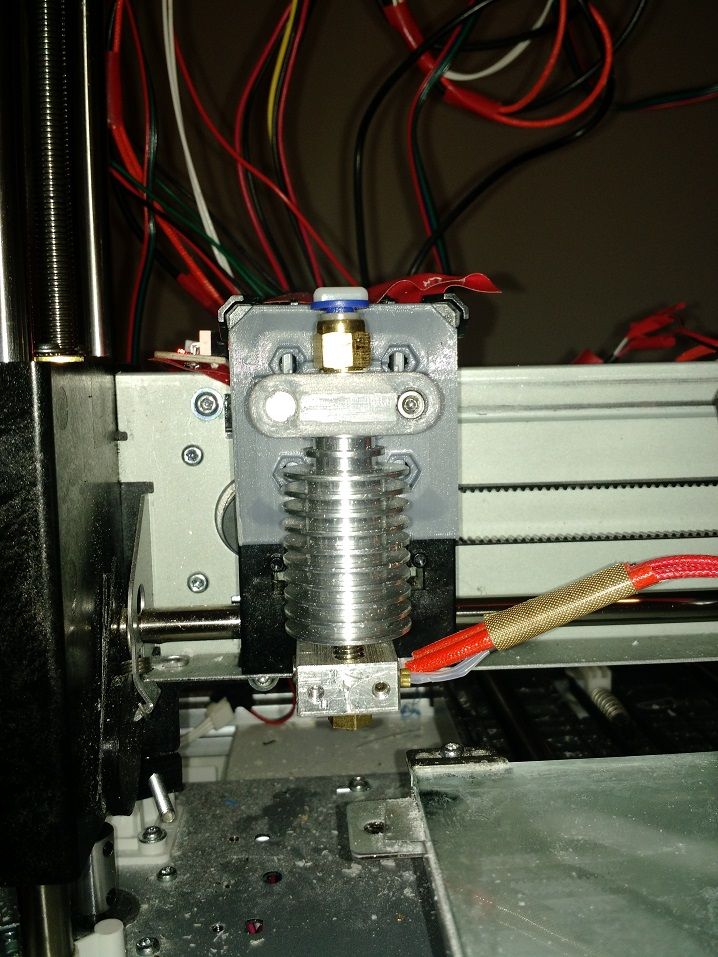

By looking at it it seems to be all metal one, can't see any lining inside or so.

If it's all metal one then in theory (if there's no firmware limit) I could do filaments like Nylon or even PC (doubt it though, 300c is quite high at the end of the day)...

I've been designing new hotend assembly/head to accommodate E3D v6 - all metal if there's no soft limit on temperatures or Lite6 if soft temp limit's in place so I can do abrasive filaments and only change nozzle when worn.

But If existing hotend is all metal one then it will save me good £40.

Regards,

Kris M