Topic: SD3 total conversion

I'm thinking about completely rebuilding my solidoodle 3 with all linear rails and a corexy or H-bot belt system to reduce the moving weight. I've searched on here but haven't come across any similar mods to what I am planning, but if you know of an older thread that would be helpful please speak up. After looking at basically every printer on the market I've determined that none of them really meet my requirements. The things I am looking for are high precision, high temperatures (PC, ultem), and large build volume. I'd love to have more than 200x200mm, but I'll probably settle for that or just a bit more than that if I can squeeze it into the SD3 frame. The frame is really the only thing I like about my SD3, it's never printed well and is really worn out. The bed has a lot of up and down slop and side to side. I've done all the usual mods and I'm still not satisfied with it. I thought about keeping the guide rods and going to linear bearings, or even upgrading to larger guide rods, but rails just seem like the way to go to me. I'm also toying with the idea of extending the case downward and putting in a longer Z screw, but most of the large things I want to print really need the layers running the other way (I mostly print mechanical parts). And another thought was to just build a whole new case, but upgrading the SD3 is going to be a lot more cost effective.

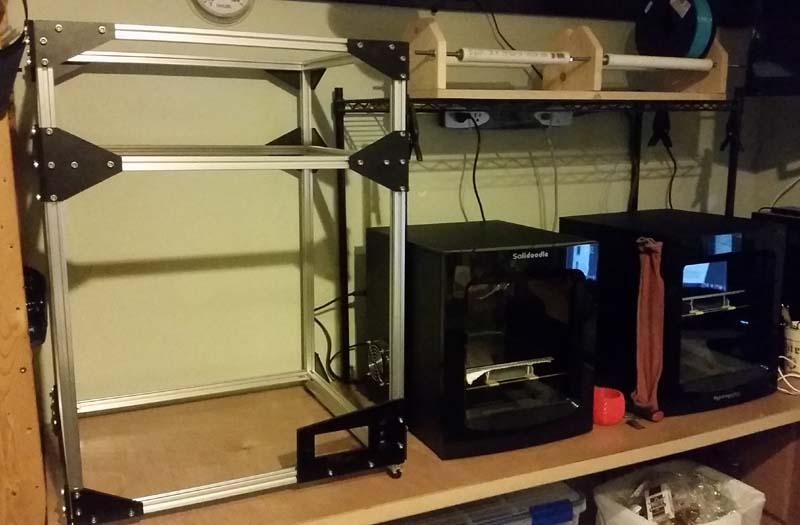

This is what I've got so far, using all 15mm rails. The Y axis rails will bolt up under the lip of the case with just enough clearance for the bearing truck to not rub the case. I'll print (or mill from aluminum) an adapter plate that will let me bolt a 20mm (18mm inside) carbon fiber square channel between the Y rails. Then the X rail will bolt to the carbon fiber square channel, and the 2 Z rails will bolt to the case wall behind where the rods used to be.

I've never seen carbon fiber used before in 3d printers, but my reasoning here is to keep the moving weight as light as possible. I've used these types of carbon fiber square channels in drones before and they are extremely stiff and weigh next to nothing. Is there any reason they are not used in printers? Or am I just overestimating the benefits?

I haven't modeled the Z carriage yet, but something similar to the stock solidoodle with a flat back plate would do nicely for bolting to those bearing trucks. I would just re-use the stock Z carriage, except that I'm pretty sure that's where most of my problems came from. The rivets loosened up a while ago so I drilled and tapped them for 10-32 screws, but even those back out time after time no matter how much loctite I use. I may just weld the pieces together and be done with it.

I've never built a printer before but I have a lot of experience building other stuff. If anybody sees any problems with this plan please let me know, any suggestions are greatly appreciated!