Topic: [ABS] PA-746

Resin: ABS PA-746

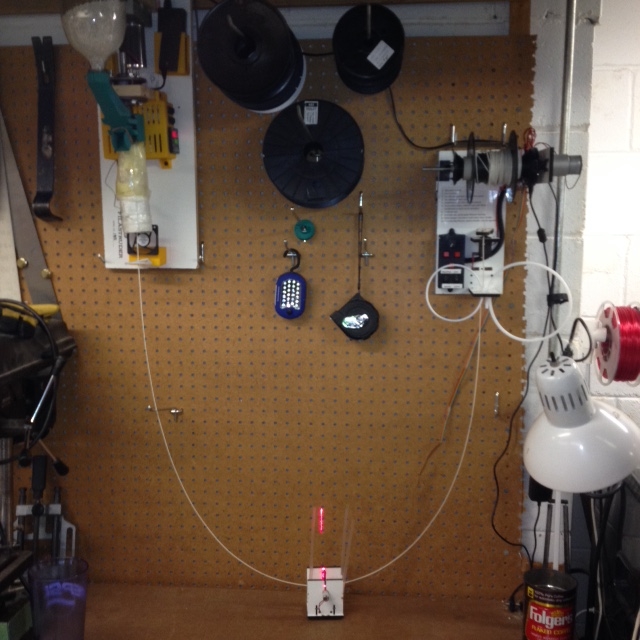

Equipment used: Filastruder #1956 ver 1.6 with 2.0 motor and 1.75mm melt filter, full barrrel insulation, vertical mount with filawinder. Beverage straws were placed over the PTFE tubing was on the laser sensor to guide the filament better. Printer is DaVinci 1.0 with custom firmware, Bowden carriage, heated glass bed, and E3D hotend.

DETAILS:

Tip Diameter: 1.6 mm

Extruded temperature: 186°C

Speed of extrusion: 21" / min

Filament diameter and tolerance: 1.65mm +/- 0.03mm

Pre-extrusion processing: Food dehydrator for 4 hours. Do not know if this was necessary but when I lived in Washington, it was either raining, just finished raining, or was about to rain.

Extruded vs purchased: Very smooth and consistent finish on the extruded filament. Doesn’t seem nearly as brittle as most of the ABS filament I have purchased. I have purchased a wide variety and I would equate the printed performance of the extruded filament as good or better than $42/kg filament I have purchased.

Printing: All printing was performed on a 90 degree bed with sugar/water coating. Adhesion was fine, no warping and prints easily released when cooled. The single-wall 100mm column was printed at temperatures from 240 to 213C (temp decreased 3 degrees/10mm) and .01mm layer height. Layer adhesion was excellent throughout. The objects were printed at 225C and .03 layer height. The objects are 1.5 inch EMT conduit tension nuts/filament guides. I find that these help limit the uncoiling of filament for my particular setup.

COMMENTS:

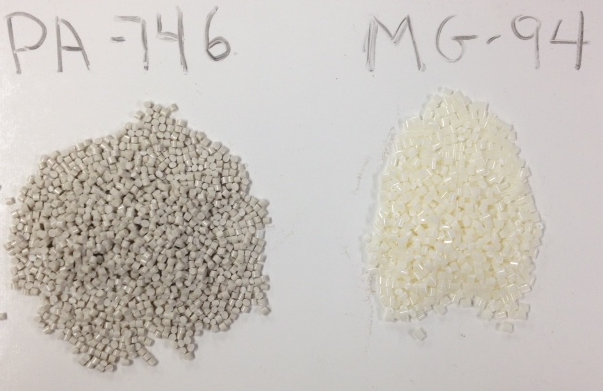

- This material was purchased from a seller in Washington state on e-bay. The shipped cost was $40 for 20 lbs. I actually received slightly over 20 pounds of actual pellets. The pellets were in a tie-wrap closed black plastic bag (garbage bag?) and shipped in a flat rate priority mail box. I ordered on a Wednesday night and received the package on Saturday (3 day turnaround). The pellets have a slight chemical odor, similar to the scent of Sevin Dust but not as strong. The odor didn’t intensify or go away while dehydrating. I did not notice the smell while extruding or printing. The pellets were consistently sized, slightly smaller than MG-94 pellets from OS3dP. The material is also slightly gray in color compared to the off-white of MG-94. I am attaching photos showing the comparison with MG-94 pellets. There was no foreign material or appreciable dust/bits in the bag with the pellets.

- Extrusion was performed at 186 degrees and resulted in consistent 1.65 mm filament at 21 inches/minute. I have approximately 2.5 feet vertical drop in my setup. This same arrangement and temperature results in 19 inches/minute and 1.70mm diameter MG-94 filament.

- The extruded filament is more opaque than MG-94 and is very similar in color to the color of most computer equipment from the late 1980s. Sort of a beige putty color.

- I wanted to see how colorants worked with this filament and added consecutive small batches of the following:

50:1 ABS red

50:1 ABS orange

50:1 ABS yellow

All colorants were from OS3dP. Color saturation was consistent. All resulting colors were consistent and had a “creamy” look. The red came out pink which is consistent with my results using this ratio with MG-94. As the colorant mixtures cycled, the color ranged from pink, construction orange, light orange, mustard yellow, light yellow. Extrusion rate and diameter remained the same as the non-colorant pellets.

My setup

Pellet comparison

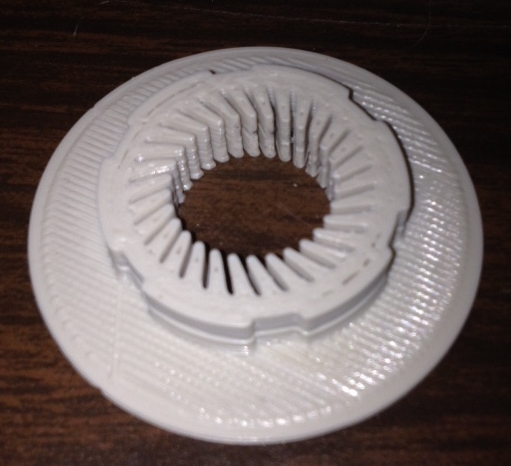

Filament produced