Topic: 3DXTech Carbon Fiber ABS

I bought this spool of CF ABS a while back and am just now getting around to testing it out. (finally got #2 up and running with the E3D v6 & hardened steel nozzle, just for this)

Diameter: very consistent over a couple of yards with only 0.02mm of variance - average of my spool is 1.7222

Roundness: Quite round in the couple of places I tested. Virtually no variance

Straight off the spool, it is brittle and will snap fairly easily. It does not have the give that regular ABS has

Print testing:

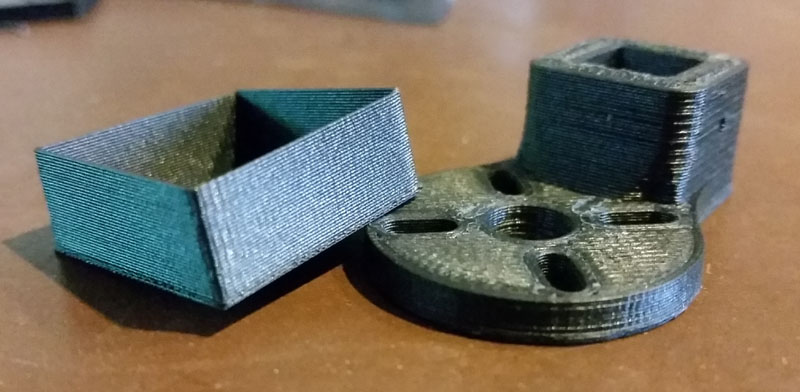

Standard calibration cube, single wall - looks very nice and smooth.

RC plane motor mount at 90% infill - came out quite well. This was printed in multiple materials with the same print settings to test weight...

Temperatures

Hotend temp: I did need to adjust temp a little (i think the hardened steel nozzle may play a factor in this) my "normal" temp for ABS on #1 with the standard brass nozzle is 235-237C - I had to bump temp up to 245C on #2 for this to get good flow and layer adhesion.

Website claims 220-235C

Bed temp - my usual 100C with hairspray. Stuck down well with no lifting on the smaller parts that I ran.

The cooled plane part is quite rigid - more so than a regular ABS part would be. This would be particularly useful if you are into printing RC copter parts and such.

First impressions: So far, I like it. Still need to tweak my settings a little to get optimum prints with it, but so far, it is printing well and looks good as well. Has a nice dark charcoal color to it - not a black black.

It definitely has a slight texture to it - not silky smooth like a regular ABS print but a little coarser, like very fine sandpaper. (i can understand how a brass nozzle would be eaten up by this)

SD4 #3 - in the works ~ Folgertech FT-5, rev 1

Printit Industries Beta Tester - Horizon H1