Topic: Couple Questions - Nozzle Diameter - Spool tightness etc...

Hi All

I have my filastruder working ok now that its mounted vertically.

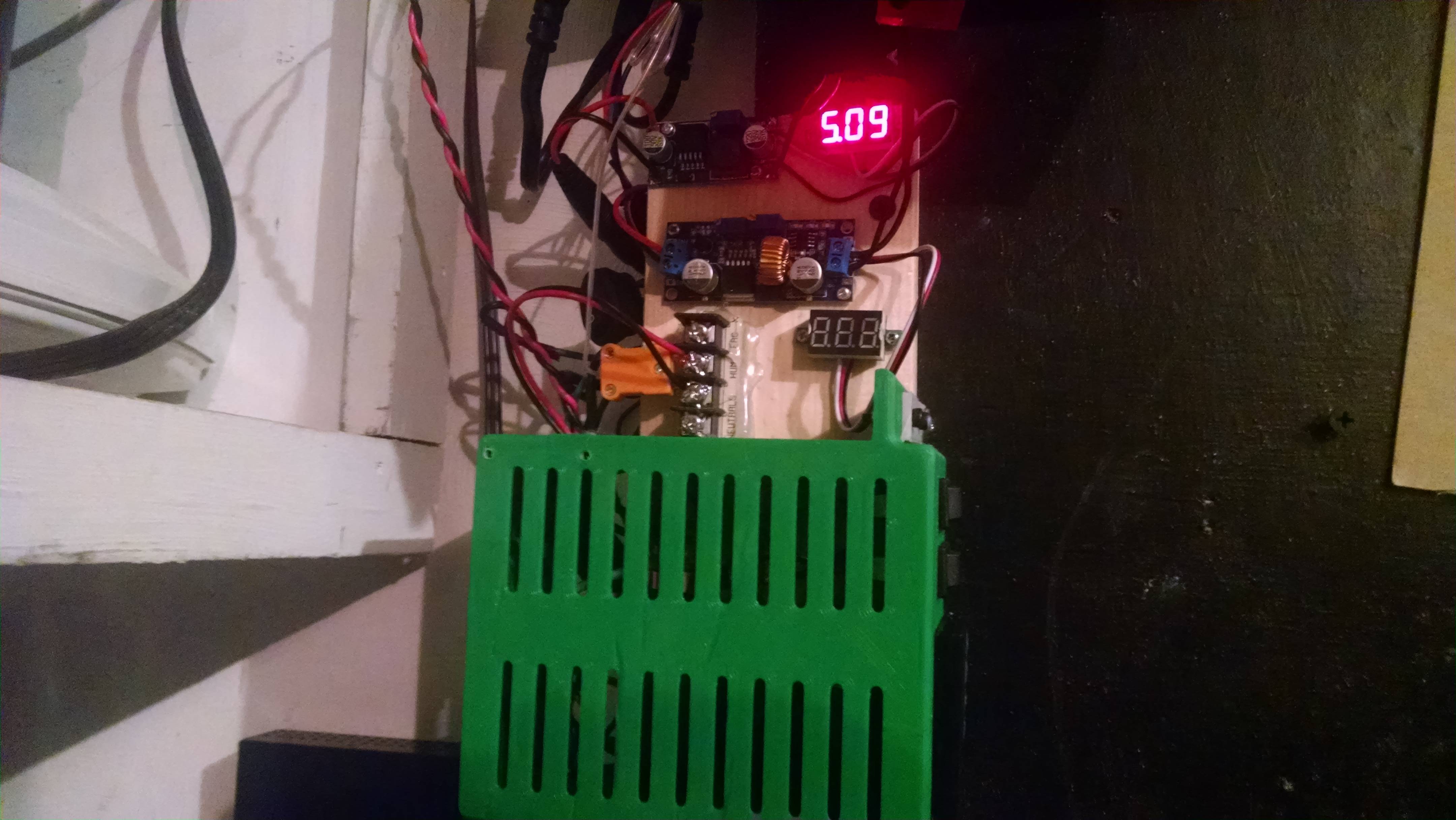

I have a fan from an xbox controlled by a variable supply, with a nice 3d printed shroud.

So i can vary the cooling as needed.

If anyone wants the shroud, I can upload the file.

My thermocouple is potted into the nozzle.

I recently moved all the electronics away from the motor end.

So now I can actually remove the motor/barrel by just disconnecting a couple connectors, without rewiring, which is nice.

Also the eventual plan is to enclose the entire motor end of the thing to cut down the noise, so moving the electronics away made for more room. Also cut the board on the bottom, so that the wood would not pass through the sound box, only the steel tube. And mounted the whole setup on ceiling tiles. Plan is to make the soundproof box out of ceiling tiles and egg crate.

There are a couple things I think I need to do, but want to get suggestions.

1. What nozzle diameter have you drilled out your nozzle to? I'm thinking a bigger nozzle will be needed for PLA. Having a nozzle for each type of plastic is livable.

2. Has anyone come up with a good way to keep more tension on the spool when the filament is being wound up on the filawinder? I'm not exactly sure what is going on at times, but my filament doesn't end up being super tight on the spool. So in the end, I'm only actually getting about 600 grams on a 1kg roll, before the filament overflows the spool, and then tangles on the filawinder.

3. I have been using old electrical spools, but some have an inner diameter that is too small for the 3d printed gear adapter. Anybody come up with a version to handle smaller diameter spools?

4. Anybody have a good thickness gauge rigged up to automatically record thickness? Specifically looking for a design that uses two bearings so the filament rolls through the measuring apparatus.