Re: DaVinci 1.0 print issues

Unless there is a mechanical bind or loose belt(s), check the wiring. This printer is well known for bad electrical connections.

First check belt tensions on all motors - very loose belts cause skipped teeth and lost position, which, short of a loss of power/connections, is probably your problem...

Prusa i3 (two built from kits), 1 hacked DaVinci

Solidworks for models, Netfabb to repair, Repetier/Slic3r and Simplify3D

Re: DaVinci 1.0 print issues

Belts are tight (very little wiggle room) so I will have to check the electrical connections next then. This is actually my 4th printer as I kept getting them delivered with varying amounts of damage (thank god for Amazon prime).

Ill check connections and report back

Re: DaVinci 1.0 print issues

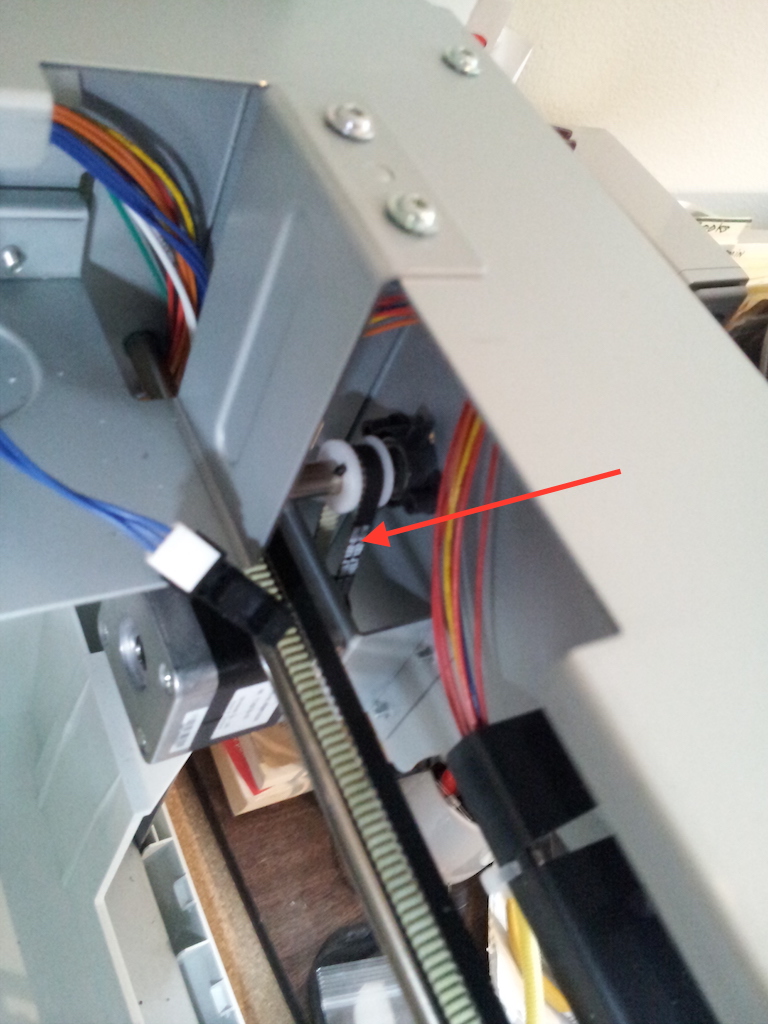

In particular, the belt shown in attached photo...

Prusa i3 (two built from kits), 1 hacked DaVinci

Solidworks for models, Netfabb to repair, Repetier/Slic3r and Simplify3D

Re: DaVinci 1.0 print issues

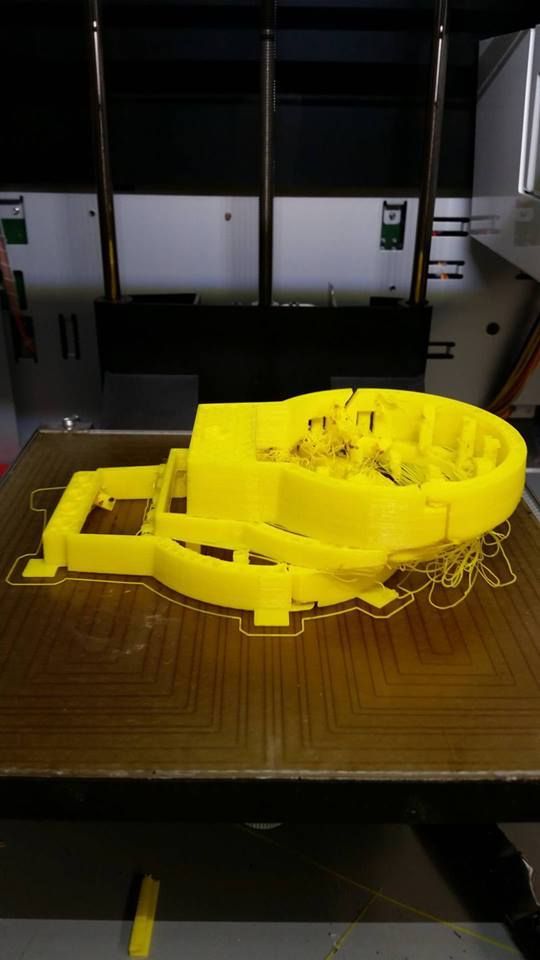

That belt is fine and tight. Its the other axis thats giving me the issues. Though I just printed the same part again and had the same thing happen at the same levels. Im thinking in this case its the way the file is being processed through the software and not a mechanical issue.

Im going to reslice and see what happens.

Re: DaVinci 1.0 print issues

Check the motor temperature. It should be just touchable. If it is hotter then you need to put a fan on the motor. It is already known that the mainboard and firmware is the Da VInci is majorly over driving the motors. This is evident by the sound levels. Any one who has converted to a RAMPS 1.4 and dialed in their motor current have a machine that is so quite it can't be heard while standing in the same room.

So knowing this, motor heating is a big issue with some of these machines.

Another problem is the endstop cables being loose or even damaged.

The logic on this machine works in such a way that when you home all the axis and the sensors get triggered or blocked active low the logic marks that as home for each axis and it moves X steps from X axis per the Gcode.

Now here is the issue. The sensors are always high and it takes an active low to trigger. Now if a cable is loose or there is an intermittent due to a break then if that break happens mid print it will see the needed active low and mark that point as the new home and print X number of steps from that point causing a shift. I have seen it happen on both x and y axis.

Anycubic 4MAX best $225 ever invested.

Voxelabs Proxima SLA. 6 inch 2k Mono LCD.

Anycubic Predator, massive Delta machine. 450 x 370 print envelope.

Re: DaVinci 1.0 print issues

I know this Is a older post but I'm really hoping someone found his actual problem as I kinda have the same issuse

Re: DaVinci 1.0 print issues

Most likely it was a problem with the wiring to the x axis carriage assembly. Specifically, the wiring for the motor wires. I've had to replace mine twice because they would randomly lose connection on one of the 4 wires, causing a shift in the print. Upon replacing the wires, the printer functioned as expected again.

Personally, the first time, I cut the wires about 3 to 6" from the connector to the motor, and spliced in new wires that were long enough to reach the connector by the main board, and then spliced in the main board connector.

The second time, I replaced a motor and used the replacement motor's wire harness to replace the cable to on the x axis carriage.