Topic: Introducing FilaFab - Filament fabrication and winding

Hi all,

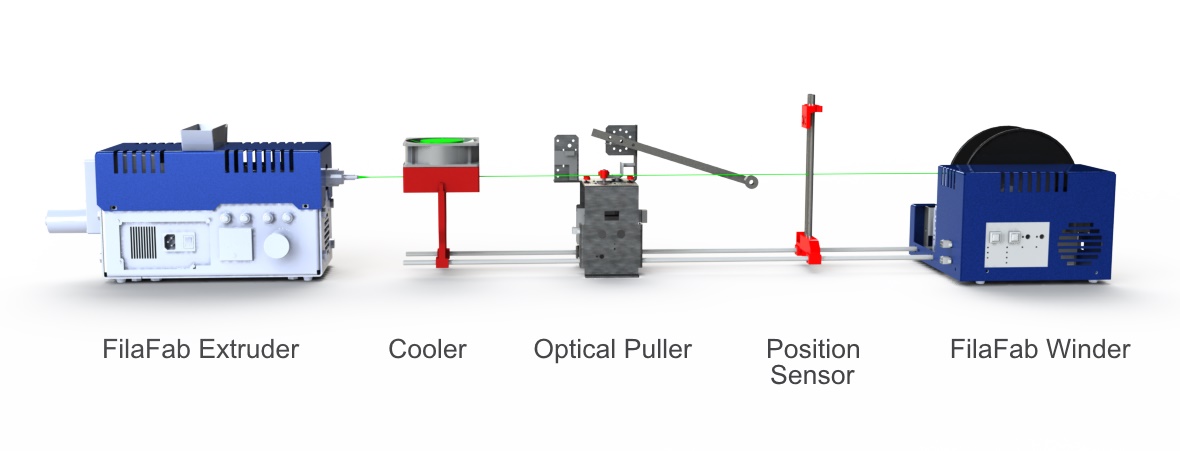

I am the MD of a company called D3D Innovations which designs and manufactures FilaFab, the Filament Fabricator. FilaFab can extrude many types of plastics and is designed to lower the costs associated with 3D printing as well as improving sustainability by reducing waste.

FilaFab was launched on Kickstarter with two seperate campaigns which were both successfully funded. For those of you who are interested our latest campaign for our new generation extruders and winding system is still open to backers through our website http://d3dinnovations.com/filafab/

The campaign can also be found now on Indiegogo for a limited time https://www.indiegogo.com/projects/fila … 10768485#/

In other news, we are about to begin testing PET (polyethylene terephthalate) and PS (polystyrene) recycling using FilaFab, the process will involve shredding drinks bottles and other items like yoghurt pots before extruding into a filament. I would be particularly interested to hear from anyone who prints with these materials or who could recommend a suitable printer for these materials.

I look forward to posting, what I hope, will be some interesting content and to discussing 3D printing.