Topic: Frosted Lexan Print Bed

Wanted to toss this one out there since I have been having great luck with prints using this method. I have printed ABS on just about everything recommended... kapton, painters tape, glass, glass plus hairspray, buildtak... but the best surface so far has been good 'ol lexan.

One problem... you have a thin margin of error with temperature and print head distance and voila, you waste 4 bucks of lexan and have a print permanently fused to the bed...

I stumbled on this solution after a failed print that would have left me with another ruined piece of lexan. I simply sanded off the plastic that had fused to the lexan, leaving a frosted surface. I tried printing on it and it works great!

If you dial in the temperature and height off the bed for the first layer, frosted lexan has proven to be almost fool proof. I have been printing on frosted lexan for almost a year now and I don't think I'll go anywhere else for ABS printing.

Note that I have had less luck with laywood, nylon, and ninja flex... Some don't stick at all, others make a permanent fusing to the plastic. Fortunately, if you mess up, just sand it down and you are back in business.

ABS+frosted lexan == success!

First layer temp 203C then 198C for remainder of print

Bed temperature 95C

2-3mm brim is still a good idea.

use a metal scraper to get under print and they pop off with ease.

Card paper calibration for print head height is a little too close, dial back just a bit and the first layers are great! Too close and you have a permanent fixture on your lexan bed.

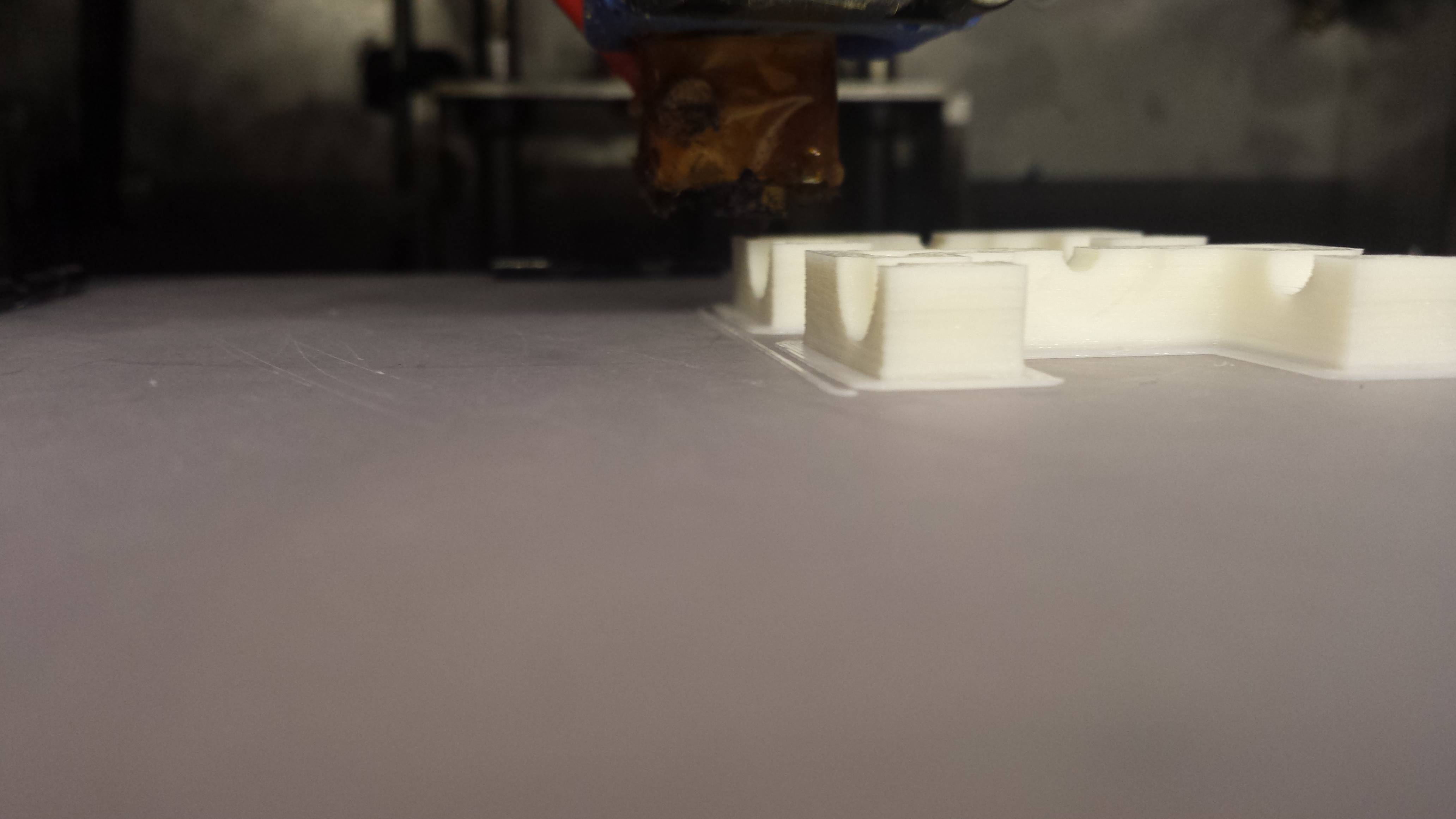

See attached image... E3D print head, M5 lead screw, .1mm layer height. The image is a print in progress of back up Y axis idler mounts for SD3