Topic: Flexible filament success!

Finally managed to print flexible filament with my press!!

And the original extruder aswell!

Video:

https://www.youtube.com/watch?v=yf-g3z0 … e=youtu.be

Attatched a pic of the testprint aswell!

You are not logged in. Please login or register.

SoliForum - 3D Printing Community → Solidoodle Press → Flexible filament success!

Finally managed to print flexible filament with my press!!

And the original extruder aswell!

Video:

https://www.youtube.com/watch?v=yf-g3z0 … e=youtu.be

Attatched a pic of the testprint aswell!

Here's my second testprint.

It turned our really good if I may say so, being printed on a press with the original extruder and everything else original except the ptfe tube and a buildtak on the glass bed ![]() !

!

The pic is found here ![]() https://instagram.com/p/52rKS9IfMn/

https://instagram.com/p/52rKS9IfMn/

would you post your stl for the fan adapter cause that thing looks awesome!!

nice job with the flexible btw!

ill try silicon oil from my airsoft gun!

WOW! thats a big plus for Press owners that had to wait so long to see if all the hipe was true or not. glad to see something positive out of it

cool, and check out this video that was after yours showing a new flexi build plate. https://www.youtube.com/watch?v=1T5BdRFlCd8

would you post your stl for the fan adapter cause that thing looks awesome!!

nice job with the flexible btw!

ill try silicon oil from my airsoft gun!

Thx alot ![]() !

!

I got the design on my thingiverse, but I will try to make a new better one in the upcoming days because the shroud sits a little too close to the heater block and the fan aswell.

The new design will have the fan mounted ontop and then the shroud going from just under the plastic mount and down to be able to make it more narrow and stay clear of the heater block ![]() !

!

I'll post the link anyways, but if you want an eaven better one stay tuned.

I'll try to remember to post here when its done!

My thingiverse: http://www.thingiverse.com/MrSnoWie/designs

cool, and check out this video that was after yours showing a new flexi build plate. https://www.youtube.com/watch?v=1T5BdRFlCd8

oh, that one was kinda neat aswell hehe ![]() !

!

Had some minor issues due to the ptfe tube was so short and only rested at the bottom of the lower cone where the filament gets feeded down so I made a new modification.

It tipped off to the side sometimes and the filament got feeded out on the side of it.. ![]()

Now it works as a charm though!

This should be made from factory, now it prints flexible filament without any problems!

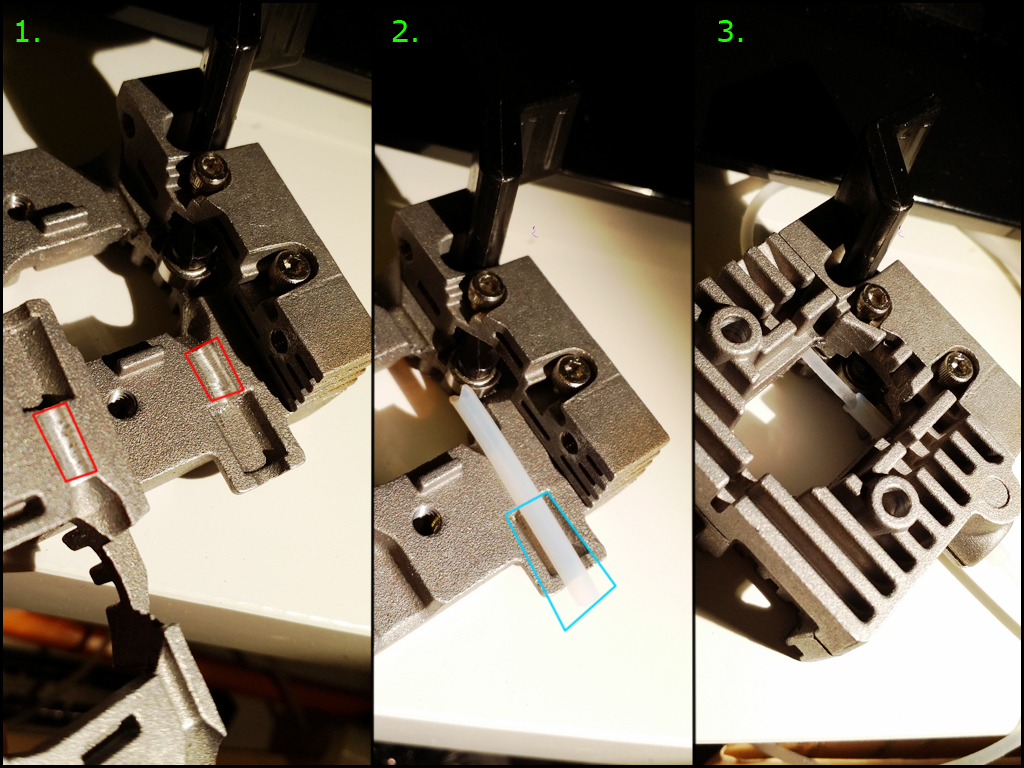

First I dissasembled the extruder block then I clamped together the 2 peices with a small twist clamp.

After that I did the following steps.

1. Drilled out the hole to 3mm, first off with a 2,5mm drill and then finally a 3mm one.

2. Cut a piece of 3x2mm ptfe tube at 2x45 degree at the top and cut it to the right length down to the hex piece and removed the remaining part I dont need.

Thats it, just reassemble it again and print like crazy!

Note to self, if anyone out there is attempting this mod and use a buildtak on the glass bed.

Then be sure to turn the glass bed upside down ![]() !!!!

!!!!

Just ruined my buildtak...

No need for heat on the bed when printing flexible so dont worry about the buildtak! ![]() and it can handle about 120c aswell!

and it can handle about 120c aswell!

Thanks for posting your solution!

Can you still print ABS with the widened hole if you remove the ptfe tube or does it have to remain on?

Where did you buy the ptfe tube? Which flexible filament did you use?

Looking forward to your revised fan adapter!

I still have the ptfe tube when printing abs aswell ![]() .

.

The filament is 3dprima.com's own TPE flexible filament, I also have someninjaflex that is half clear/milky-ish.

yeah, haven't had time fixing the fan adapter yet but it will be done, sometime ![]() !

!

Thanks for posting your solution!

Looking forward to your revised fan adapter!

It's done now, haven't had any time to test it out yet though.

Link to file here:

http://www.thingiverse.com/thing:852826

SoliForum - 3D Printing Community → Solidoodle Press → Flexible filament success!

Powered by PunBB, supported by Informer Technologies, Inc.