Re: Moire - Might not always be in the printer

Velocity is the rate of change of position.

Acceleration is the rate of change of velocity.

Jerk is the rate of change of acceleration.

You are not logged in. Please login or register.

SoliForum - 3D Printing Community → 3D Modelling/Scanning/Design → Moire - Might not always be in the printer

Velocity is the rate of change of position.

Acceleration is the rate of change of velocity.

Jerk is the rate of change of acceleration.

Hi 2n2r5,

Did you ever think of adding rickq front bed stabilization?

http://www.soliforum.com/topic/3407/fro … ed-wobble/

Hi 2n2r5,

Did you ever think of adding rickq front bed stabilization?

Yep, sure have. I have to acquire some parts. I think I may just use bearings on a spring loaded arm. I am a little concerned about how much pressure I will be putting on the sides. My bed has a bunch of play when you lift the front of the bed. I don't want introduce any backlash in the bed due to excess pressure keeping the front of the bed from falling.

Or,

I ignore the problem and build my new machine.

![]()

techbuilder2175 wrote:Hi 2n2r5,

Did you ever think of adding rickq front bed stabilization?

Yep, sure have. I have to acquire some parts. I think I may just use bearings on a spring loaded arm. I am a little concerned about how much pressure I will be putting on the sides. My bed has a bunch of play when you lift the front of the bed. I don't want introduce any backlash in the bed due to excess pressure keeping the front of the bed from falling.

Or,

I ignore the problem and build my new machine.

Your so close though!

I would make this the last thing you do to your solidoodle

just so you can have closure lol

Have you tried this mod 2n2r5?

http://reprap.harleystudio.co.za/?p=321

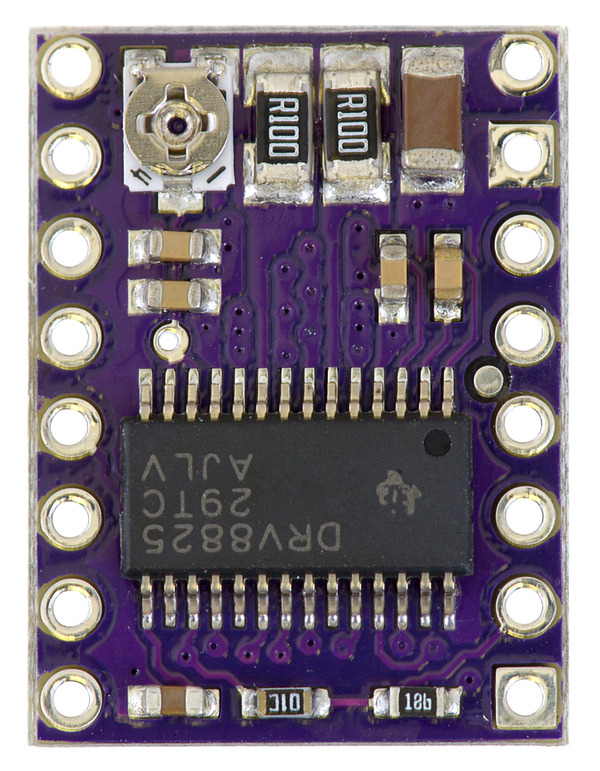

I don't know which version he did that on. I have the MD20B. That might be the MD20A which needed a hack to get to work correctly. Adrian ended up with those. I think it needs a 4.7K pull up resistor in-line some where to work. I do have a couple spare DRV8825 md20b drivers that are questionable. I will test this out and see how it does.

I don't know which version he did that on.

If you look at the pic closely at the photo on http://reprap.harleystudio.co.za/?p=321, it shows the '01C' connection, which makes it a MD20B.

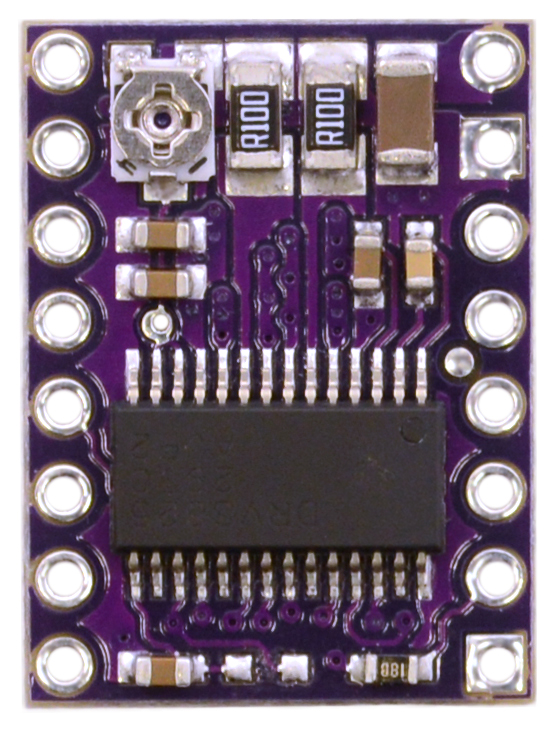

MD20A:

MD20B:

I think everyone will find that running 1/32 microstepping on ALL axi (particularly with a fine-pitch z-rod) means you slam into Marlins 10KHz planner limit... 40000pps which often has 4 steps a planner loop, which means its a 10khz limit .... looong before 'decay' becomes an issue...

SoliForum - 3D Printing Community → 3D Modelling/Scanning/Design → Moire - Might not always be in the printer

Powered by PunBB, supported by Informer Technologies, Inc.