Topic: KISSlicer

Has anyone got a complete settings for KISSlicer or is this correct? (taken from what Ian Johnson said over on the google groups)

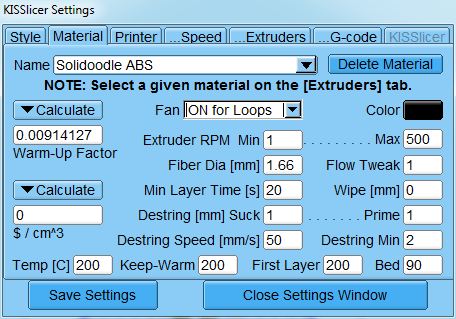

To use it with Solidoodle in the Material Settings tab, set the Max Extruder RPM to 500 and the Min Extruder RPM to 1. Flow Tweak is the same thing as Extrusion Multiplier in Slic3r. Destring MM [Suck] is the same as Retraction Distance. Prime is like Extra Distance on Restart, and should be the same number as Suck. Set Wipe to 0.

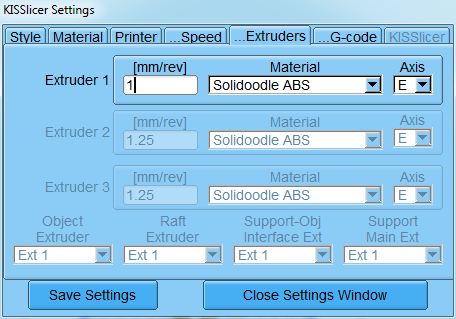

Under the Extruders tab, mm/rev should be 1. In the Gcode tab, set Firmware type to 5D - Absolute E and 5D Temp Gcode to M104. I'll need to do a full post later, but those are the settings needed to work with the Solidoodle and its stepper powered extruder.

- show quoted text -