Topic: Removing the pressed in threaded rod (pics + guide)

2n2r5 posted similar pics in the threaded rod upgrade thread, but to make it easier for everyone else, I thought I'd post pics of how I removed the rod. Add your own pics/steps if you find a simpler way!

I used simply

6 x 5/16" Nuts

1 x 5/16" Large Flat Washer

2 x Big Shifters (The bigger, the more leverage and thus easier it is on the bottom nut).

1) Remove the motor from table and printer.

2) Place the Washer onto the rod and slide it down to sit flush on the face of the motor. This is to prevent marking/scoring the motor face

3) Thread 4 of the nuts onto the threaded rod at a good spacing. These will eventually work their way down to the bottom as you tighten each of them. The bottom nut will pass cleanly off the bottom of the rod and fall into the space between the washer and the end of the rod.

4) Screw on the remaining two nuts and tighten them very firmly against each near the top of the rod to lock them off against each other. Using one of the shifters, you will grip these to prevent the rod from turning.

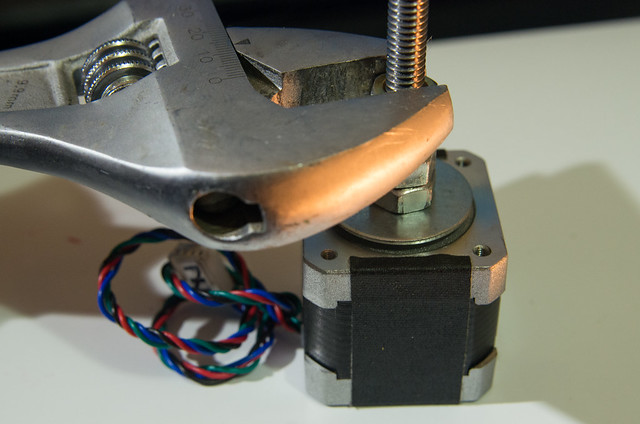

5) Gripping the two lock nuts at the top of the shaft with one shifter, use the other shifter to do up the lower nut and forcing it against the nut that is sitting above the washer. These will slowly ease the rod up as the nut moves off the bottom of the rod and stacks against the first nut. Continue to repeat this process for each nut. Here you'll see I'm just finishing the fourth nut:

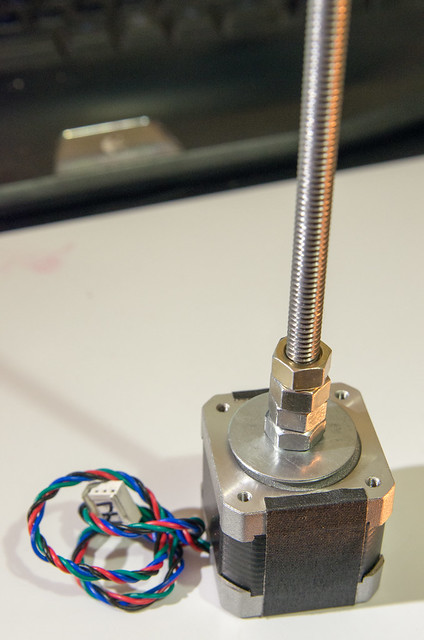

6) Eventually, all the nuts will be at the bottom of the shaft and it should take a slight final twist to remove the rod:

7) And voila! Rod removed: