Topic: Entirely new Printable Extruder and X-carriage Assembly.

This is still a work in progress.

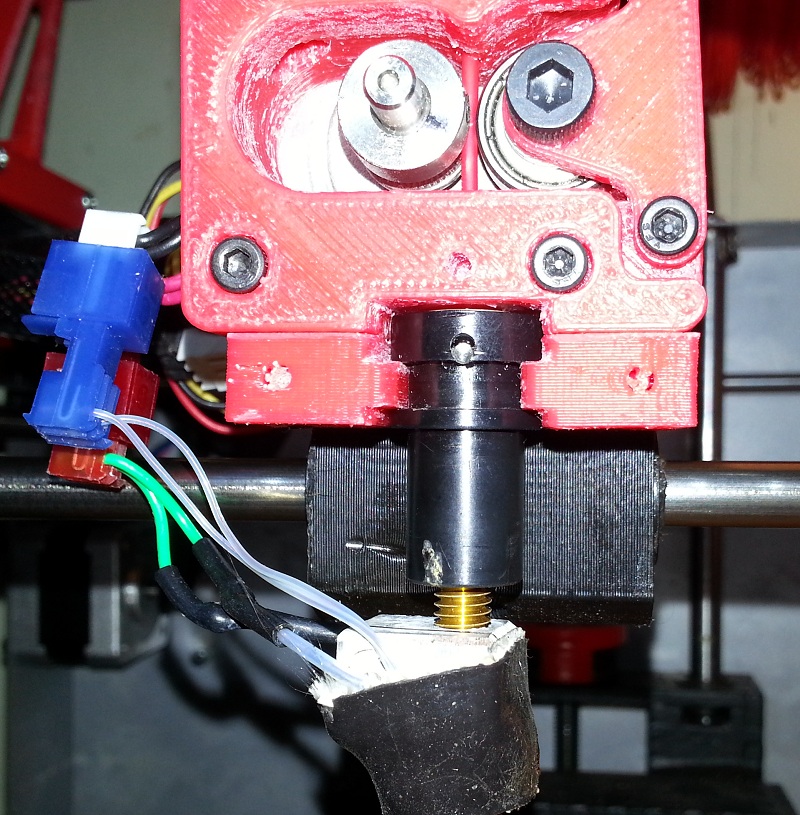

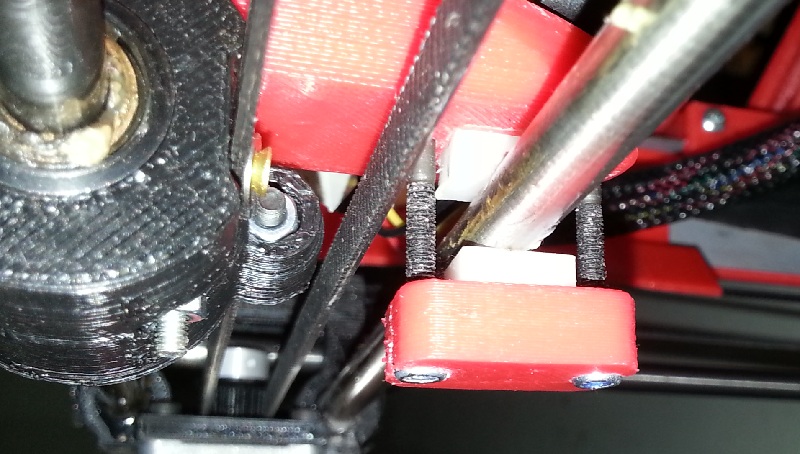

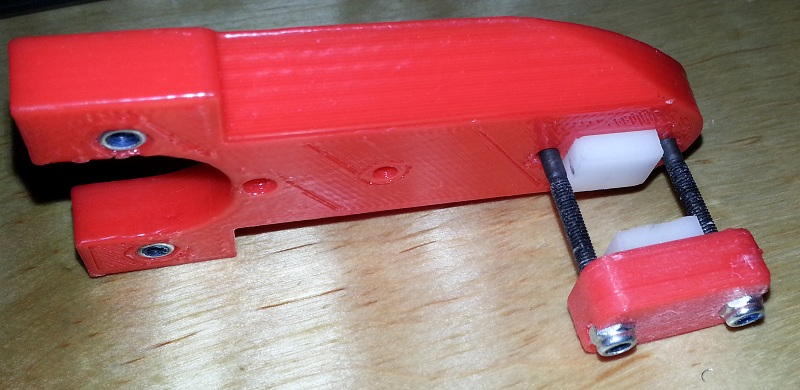

So I have been working on a new extruder and x-carriage assembly. I have thought that the previous version was just to cumbersome to assembly and disassemble. So I redesigned the extruder using things learned from Lawsy's MK4 and a few things I thought up myself. I never did like the skeletal look of Lawsy's designs they work great just not to my taste so my design is a bit more like the acrylic parts but 3d printed. This also gains about 10mm of z-travel, but be sure your z-axis screw is long enough, especially if you have a z-axis anti-backlash nut system installed. I have about 1 thread showing above the nut at start of prints on this.

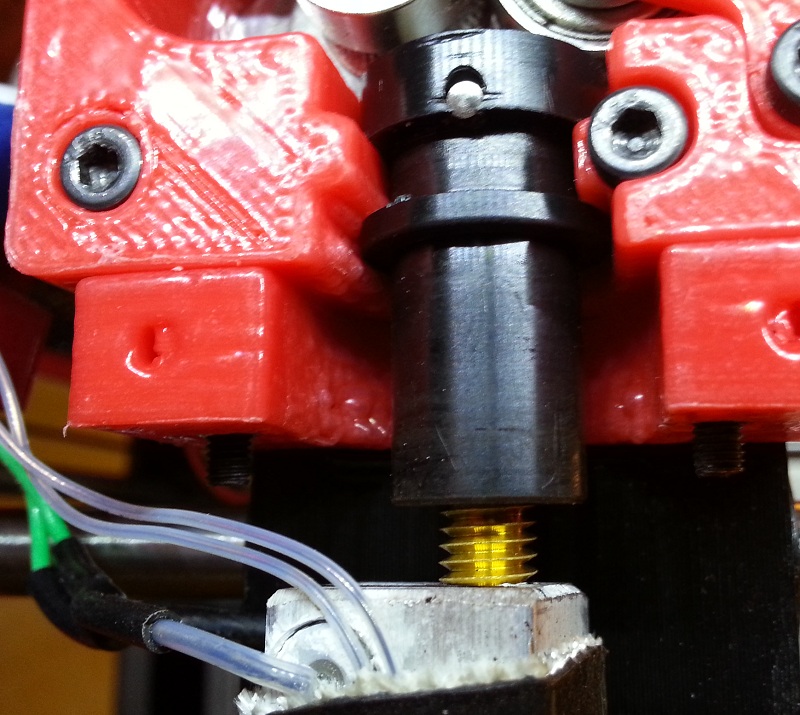

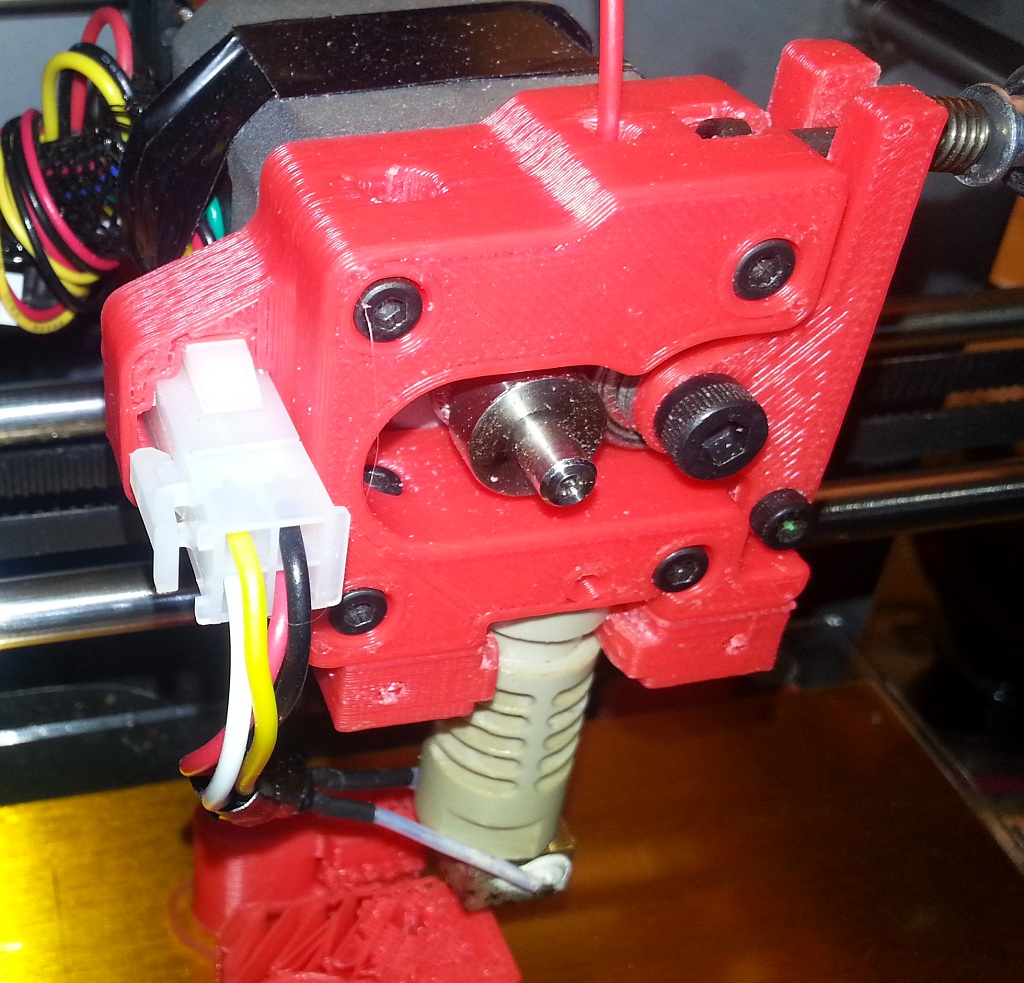

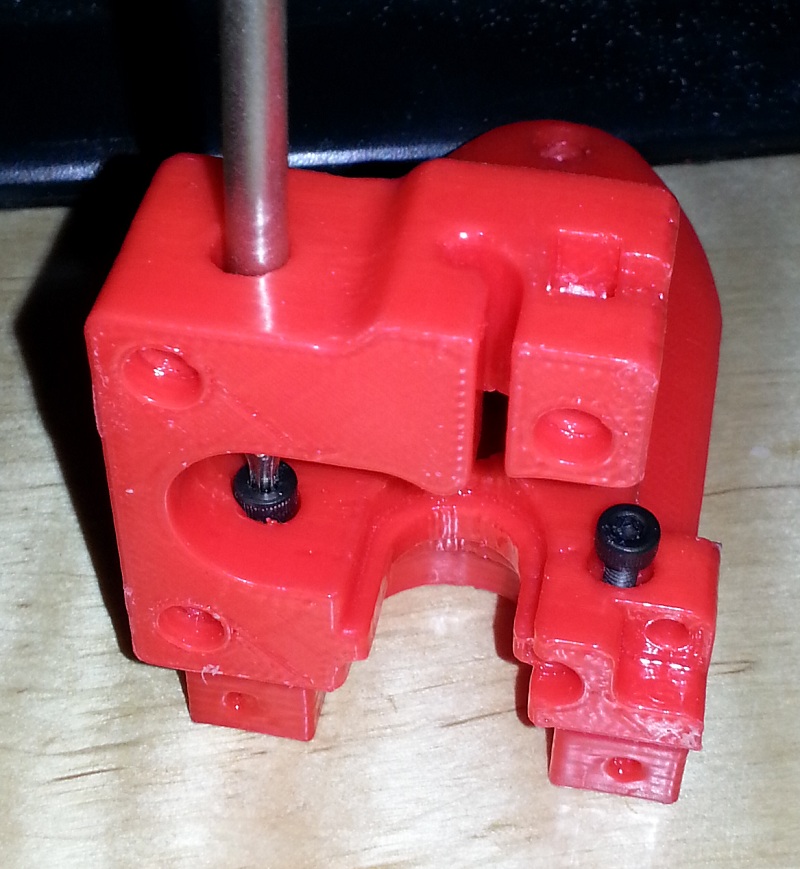

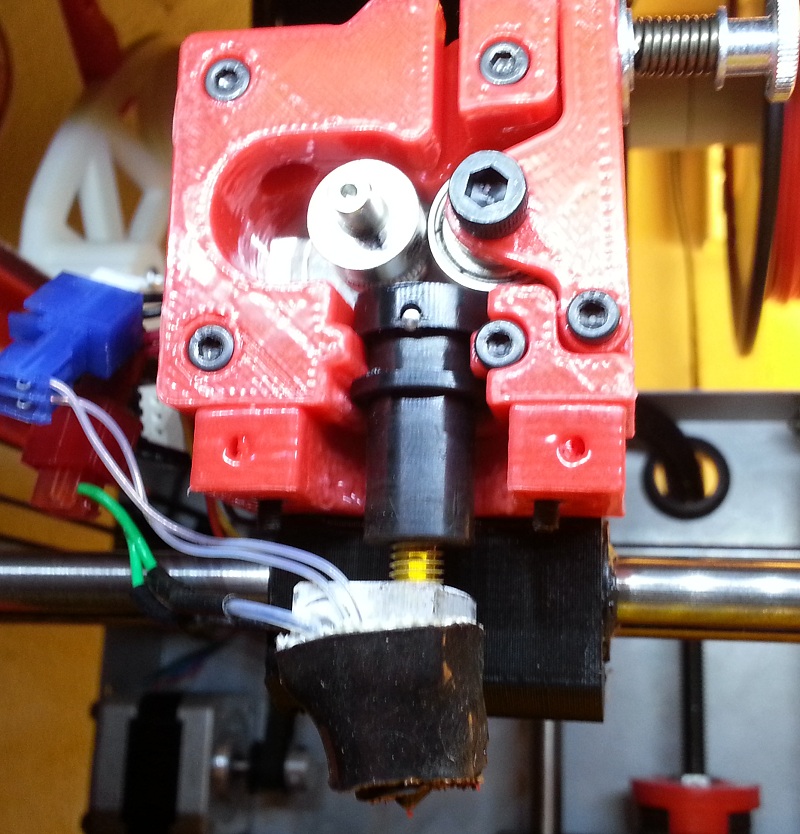

I have made a mistake though and need to correct it. To make my extruder hot swappable I removed the wood and acrylic blocks, breaking them in the process they were super frigile for some reason. And on my first print with the latest prototype of this design noticed the hotend was moving, on closer inspection the ABS was melting where it gripped the peek and where it the x-axis carriage wrapped around the peek. So it would appear the wood acted as a heat shield for the extruder assembly, I will have to figure something out to replace it, and not get in the way of hot swapping the hot end. One other thing to work on, is the clamping system for the back x-axis rod is not adjustable right now while the motor is installed. But the way it is build should not need adjustment once properly set. And you can remove the entire extruder assembly and hotend in one piece by removing only 2 screws.

This new assembly does not use any new screws, and in fact only uses 12 of the origonal screws, we shall see how it works out in the long run. All of these parts have been given an acetone vapor bath to help strengthen and smooth the outer layers.

So stay tuned, I will post the STL files soon to thingiverse if you want to experiment with it.

And now a few pictures, sorry for the quality my good camera is dead.

And here I tried to get a shot of the melting ABS... need to work on that.