Re: Filament Winder

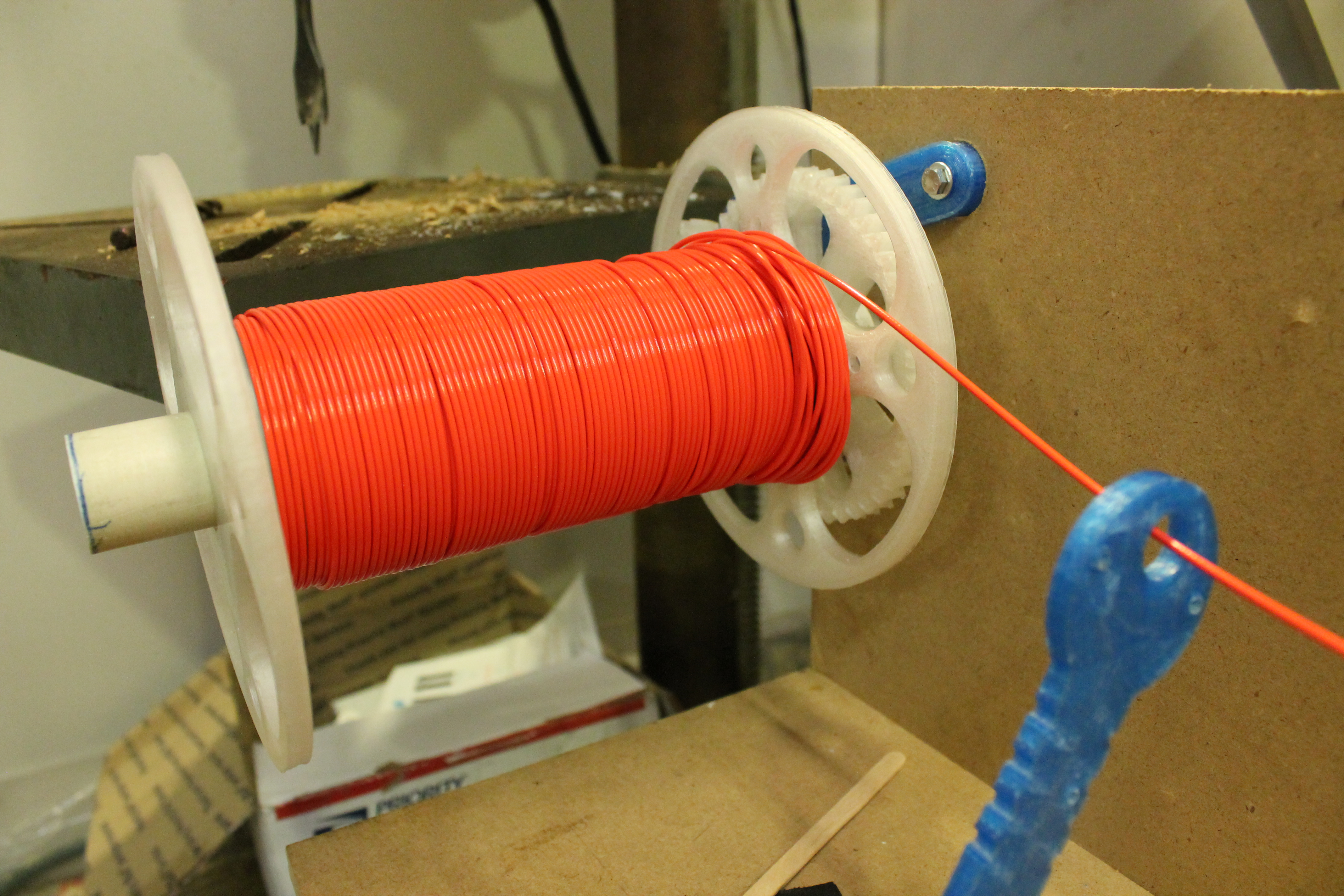

I think the key would be keeping the extruder and the puller out of alignment with each other. Because the filament is self supporting to a degree, you need a setup where if you hold the puller end of the filament, the extruder end can't continue to hang in front of the extruder. The more the end can droop from gravity, the easier it will be for the extruded plastic to push it away rather than backing into it, increasing diameter. If the extruded plastic can push away the filament ahead of it, that drops the loop. Or the filament should already be falling away. Extruding straight down gives you the second effect.

Also if the pulling is out of alignment with the extruder, then the filament is getting pulled out of the way of the plastic that is coming out. Having them face each other works over a long distance, because there is a long enough and heavy enough length of filament that gravity will pull the ends down away from the die. With a short shallow loop, the bottom of the curve can hold up the ends. I think the distance can be shortened pretty well by going straight down, then up. The extrusion may not need to be straight down, some angle may be ok. But I think the more you can align the extrusion force with gravity, the more likely a burst of speed will push the loop down rather than push into filament that isn't moving away fast enough.

I don't think the loop needs to be regulated that tightly to control the diameter. If a burst of outgoing plastic can make the loop move down, then the job is done. The control serves to keep a consistent weight hanging off the die, and make sure that over the course of hours the winder doesn't outrun the extruder or fall behind.

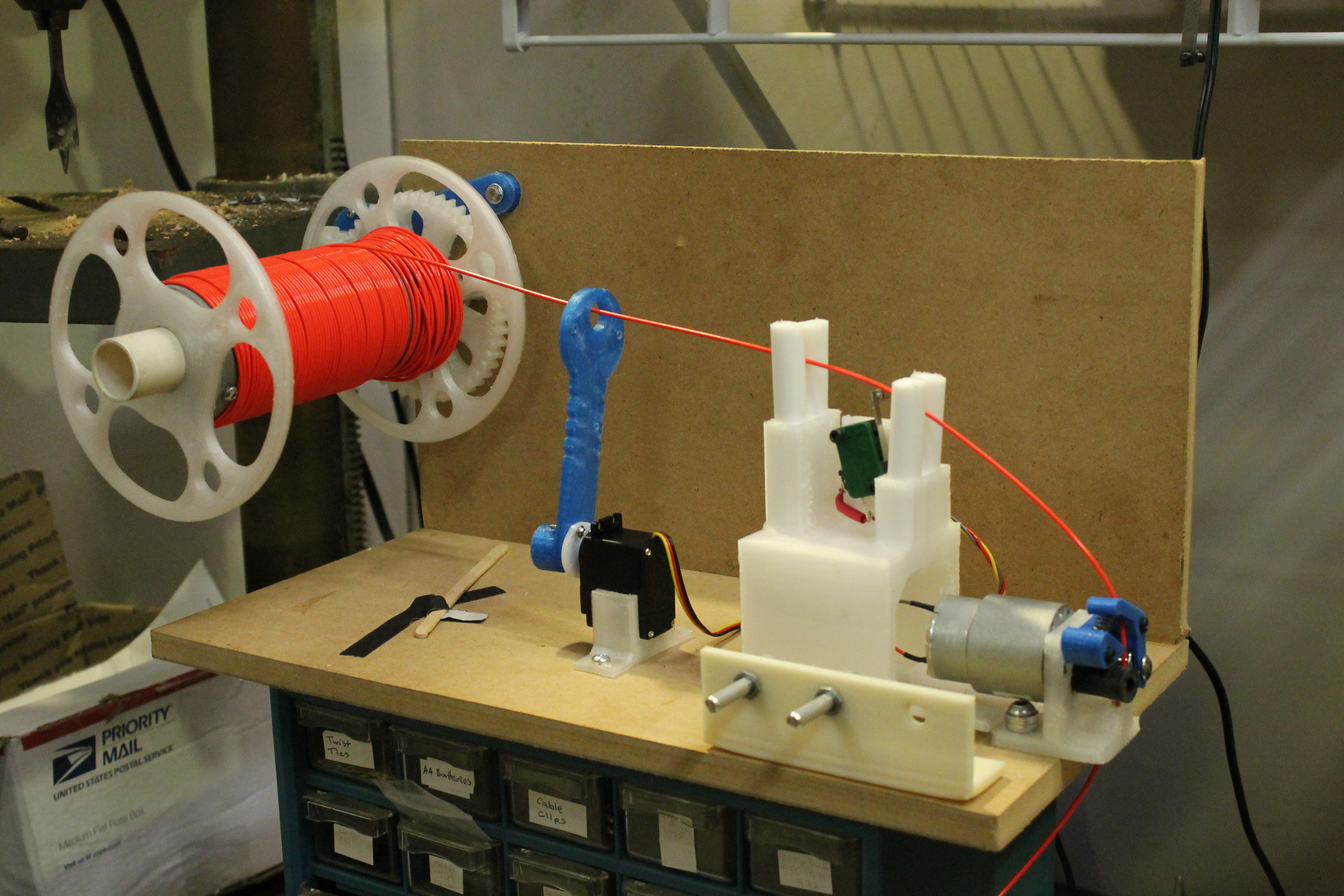

Direct drawdown would be the holy grail of filament winding, but that would require a DIY laser micrometer to attempt. It's totally doable, but I would consider that a separate project. I need to learn quite a bit more about coding to read the sensors and analyze the output, and don't want to hold up the whole project when I have what I need to finish it as-is.

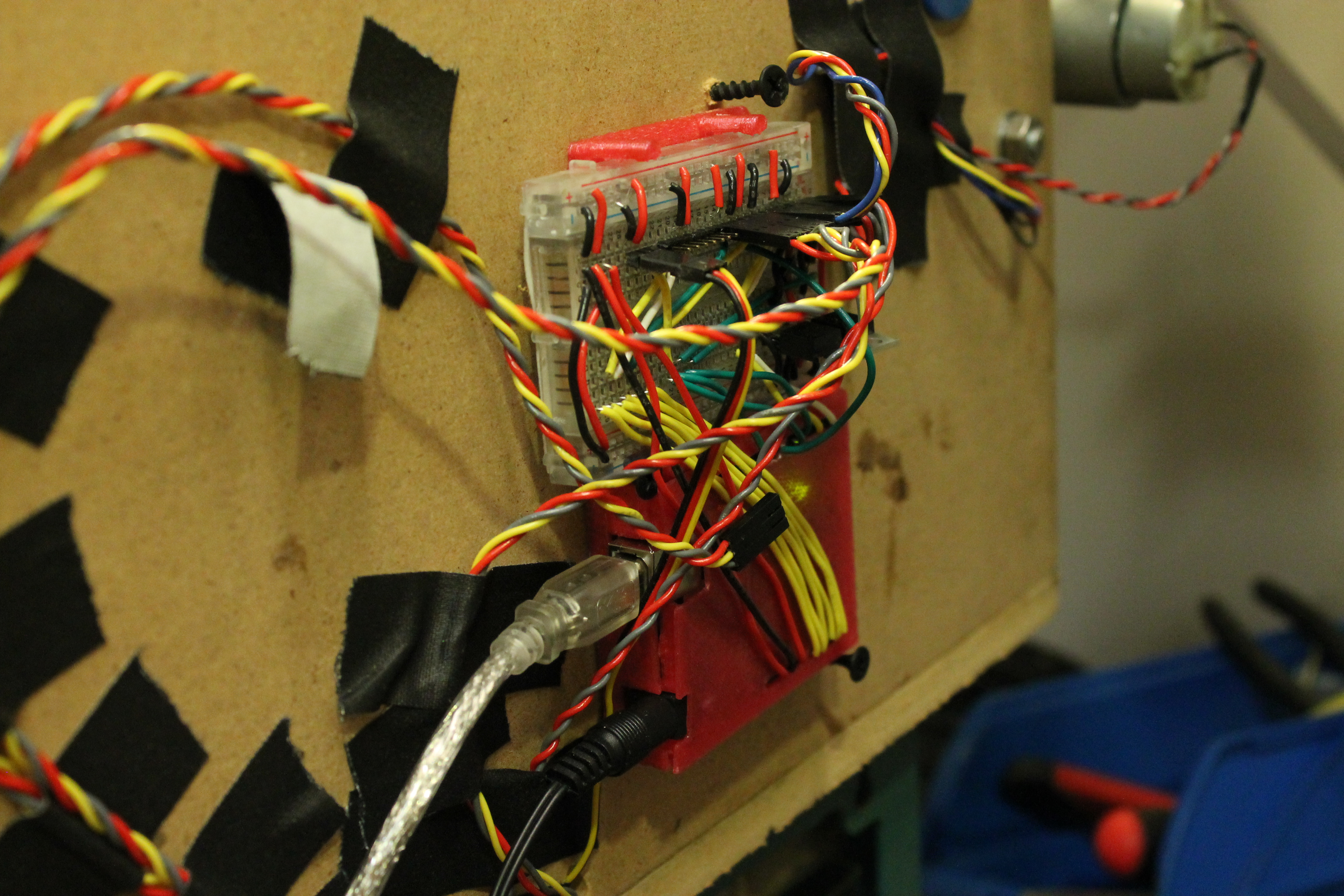

PID control with the LEDs would help reliability. I can set min and max puller speeds, but there is no guarantee that they won't be too fast or too slow if something changes with the extruder. I would like to be able to run the motor speed manually until the loop is in the sensor zone, and then hit a button to change it over to auto. If it moves up or down 1/8"-1/4", I don't really see that affecting accuracy too much.