lt72884 wrote:hmm, the web article i read the other day said z banding was the shift on the horizontal lines. Maybe they were misguided as well.

Yes, this was at 230C with hatchbox. i can try hotter and see what happens.

How could it be over extruded, if its to cool of a temp? i was under the impression that over extrusion was due to to hot of a temp causing a hiher flow rate?

thanks.

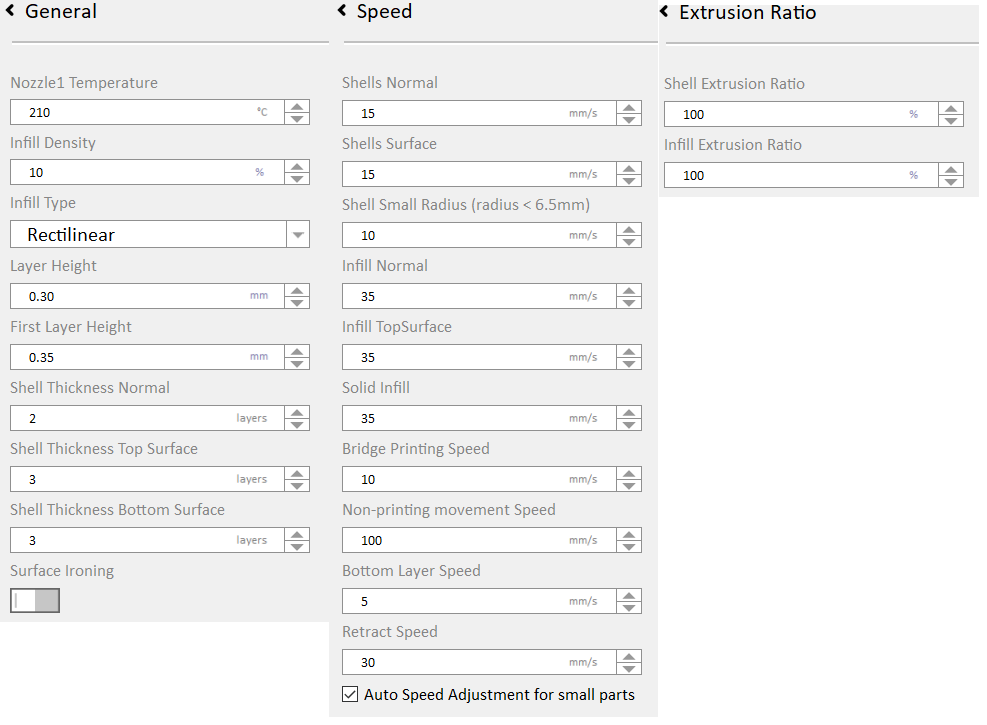

Over extrusion is caused by poor calibration. Your extruder steps per mm should be calibrated properly. Otherwise when you ask for B amount of filament you may be getting C amount instead B amount.

Under extrusion can be cause by low temp but over extrusion is caused by poor calibration or incorrect slicer settings not having to do with temp.

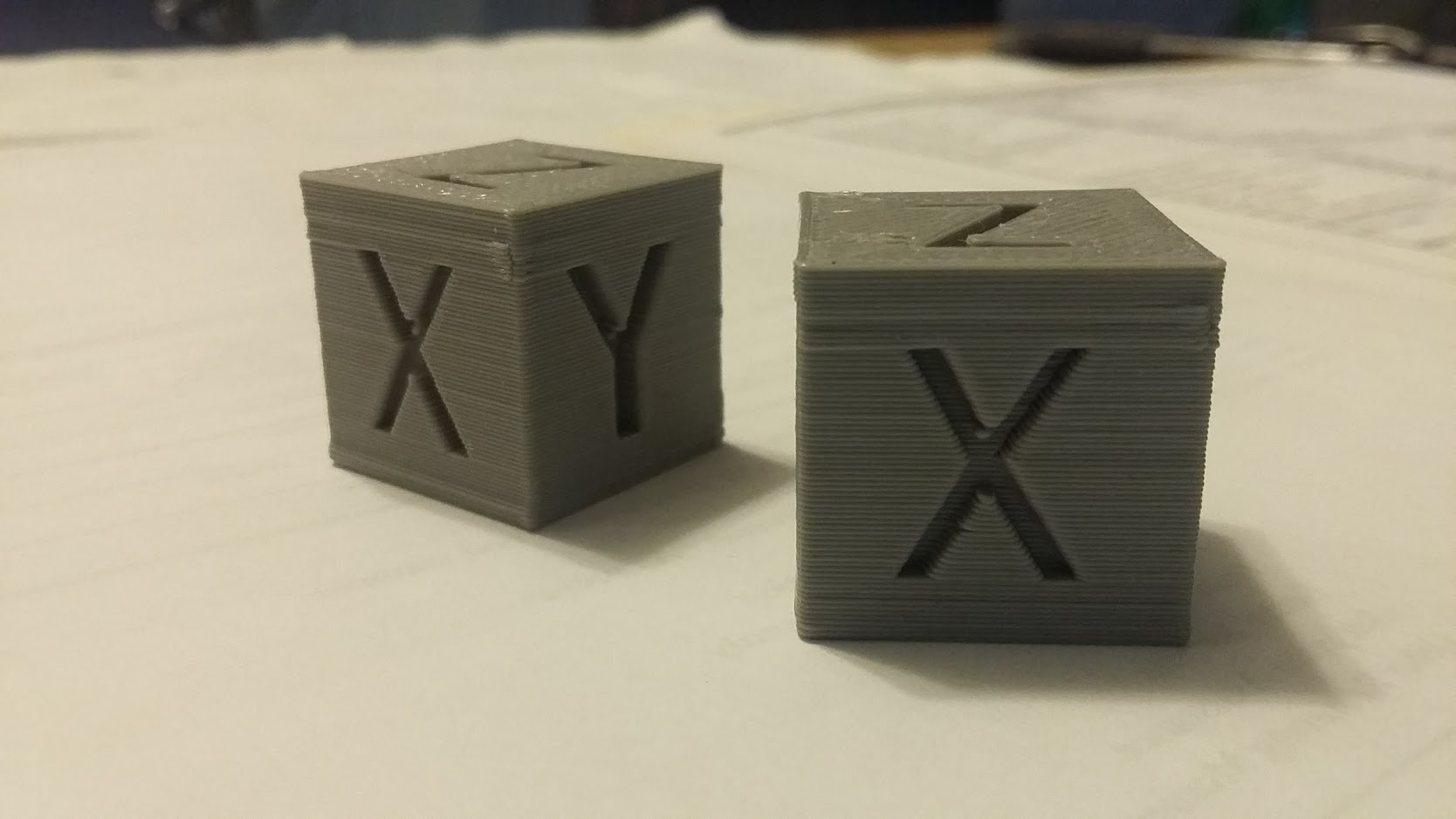

Z banding is not a shift but instead bands that appear at regular intervals along the z axis of your print. In your image I assume you are talking about the place just above the letters. That is not Z banding since it only happens at that location.

The anomaly in your image can be a caused by a mechanical issue or an electrical issue. You could have a bad wire that is stressed at that point in the print and looses connection. It could even be a bad file. Do all prints have this anomaly or just this one?

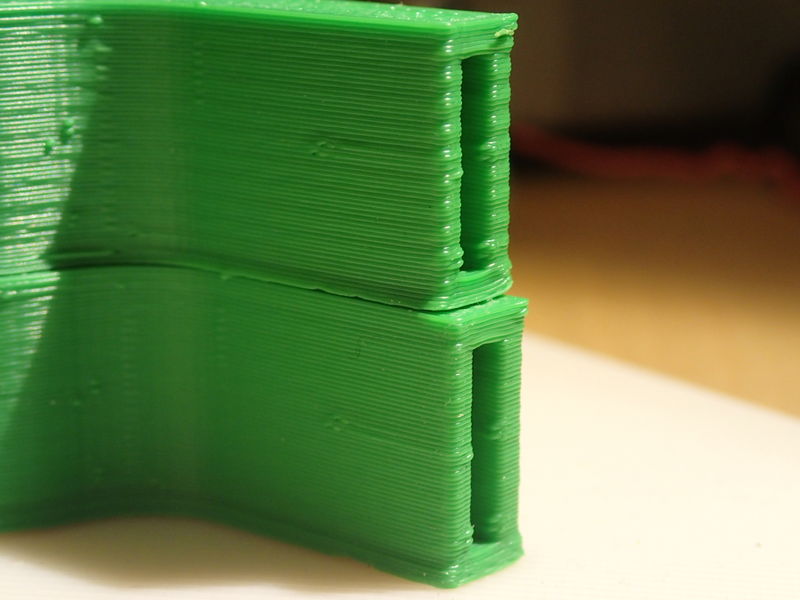

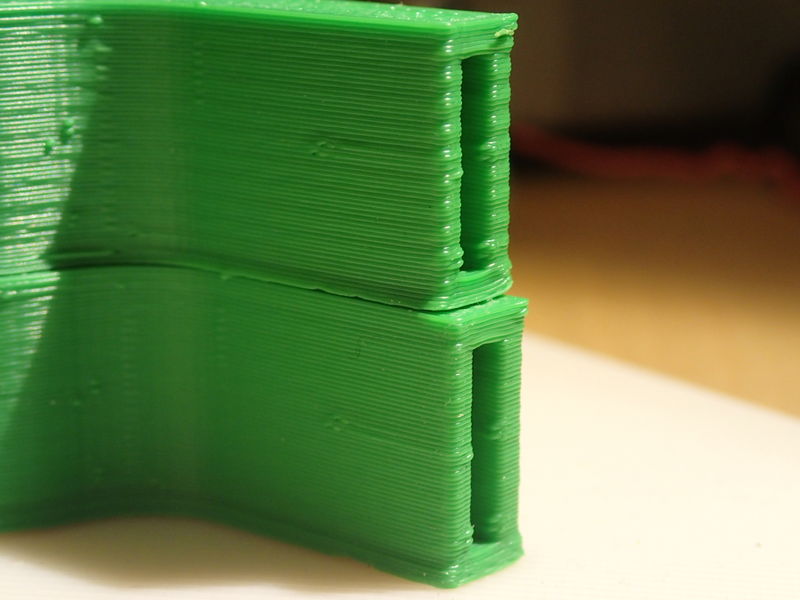

The image below exhibits banding. Two of the same objects. Normal on bottom and banding on top. Notice as I said the banding repeats at regular intervals.

Printing since 2009 and still love it!

Anycubic 4MAX best $225 ever invested.

Voxelabs Proxima SLA. 6 inch 2k Mono LCD.

Anycubic Predator, massive Delta machine. 450 x 370 print envelope.