Re: Motor Clogged?

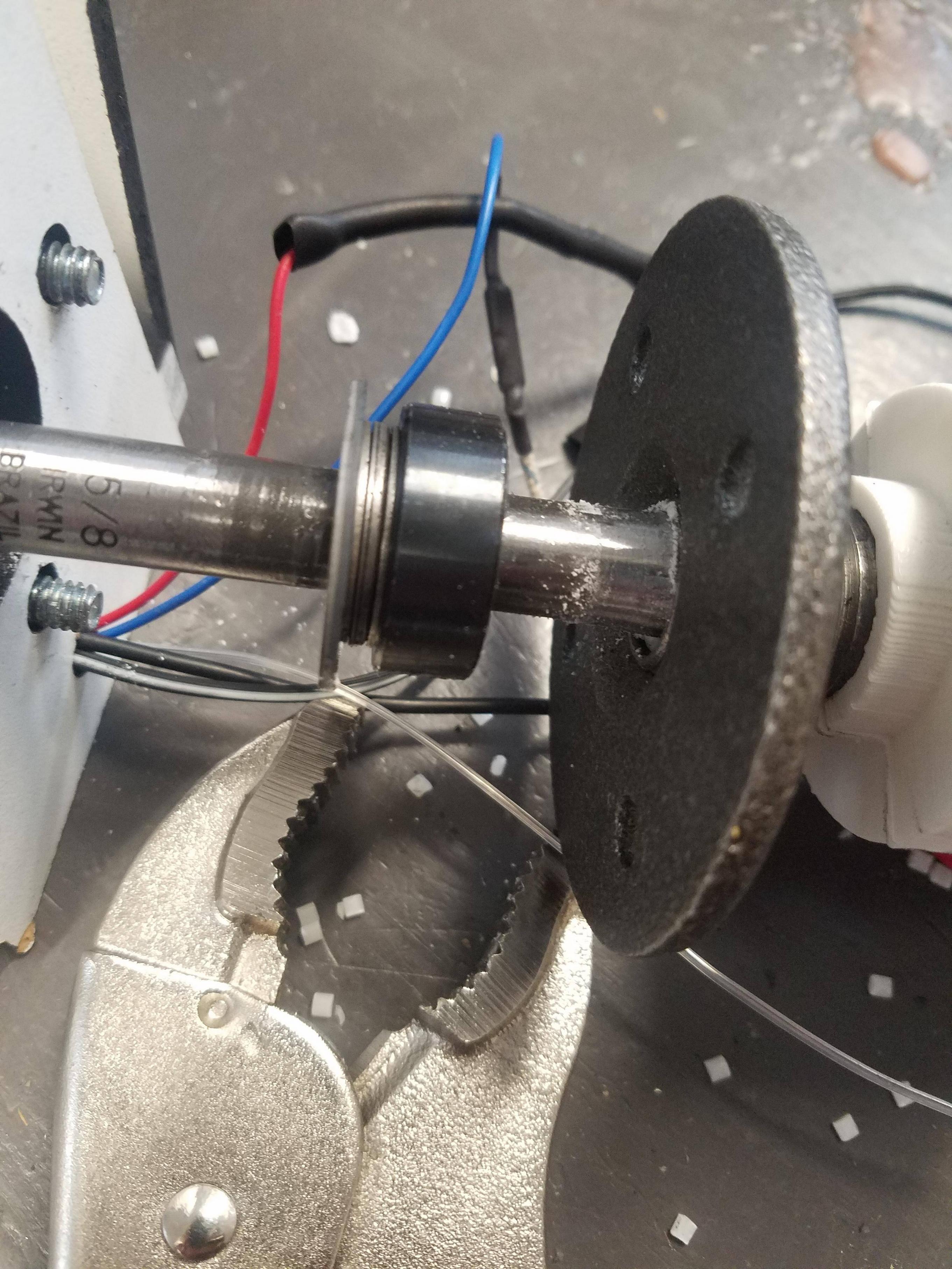

Crap, yeah thats what I figured was meant originally. The hex side of my coupler sticks a bit too well when pressed all the way into the auger, so it doesn't slide as freely as it should. But I know how far the coupler can push in towards the motor, and have enough distance that it would allow that movement if the coupler was freed from the auger. Is the movement just to represent the distance, or is the movement necessary?

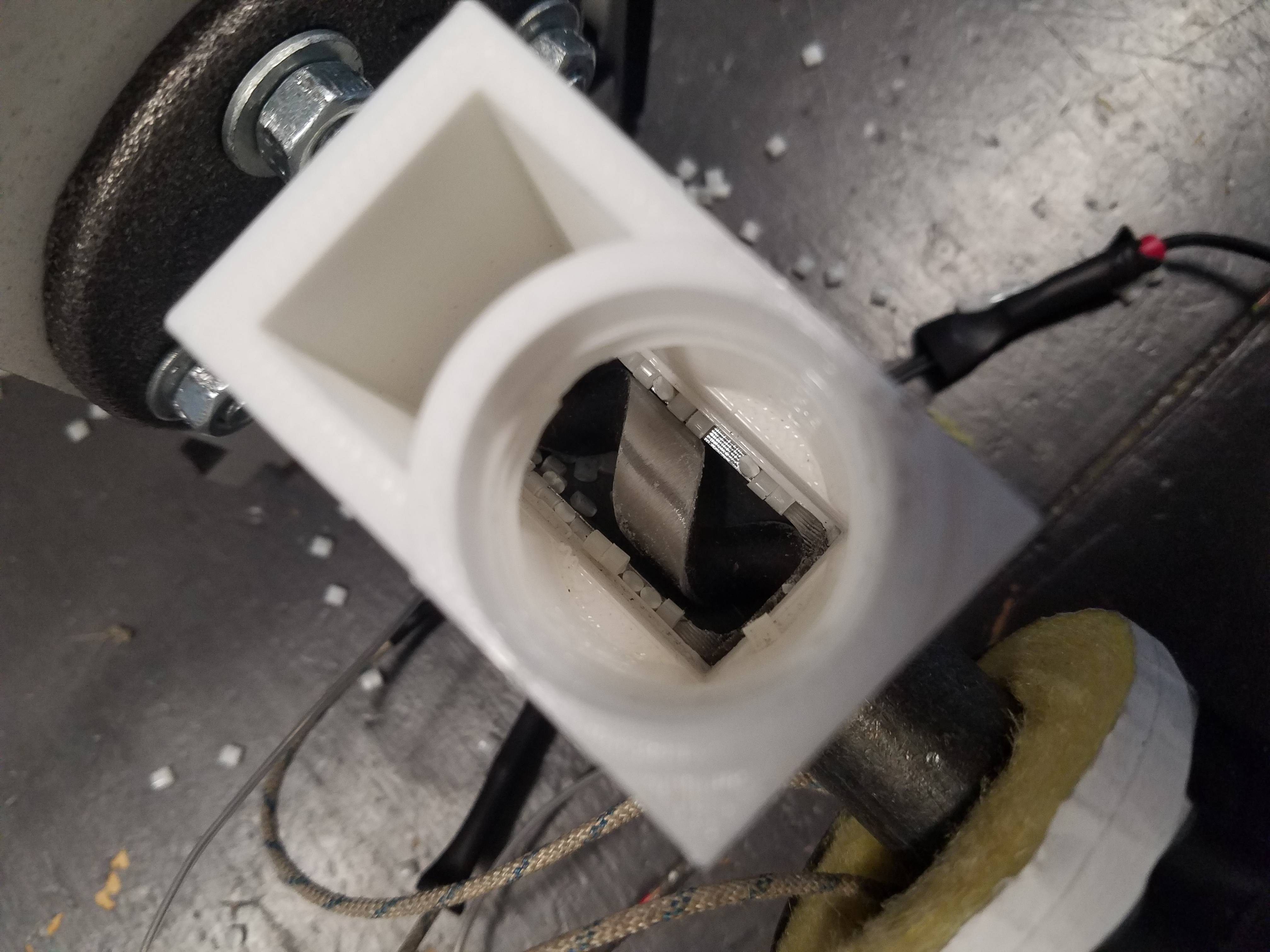

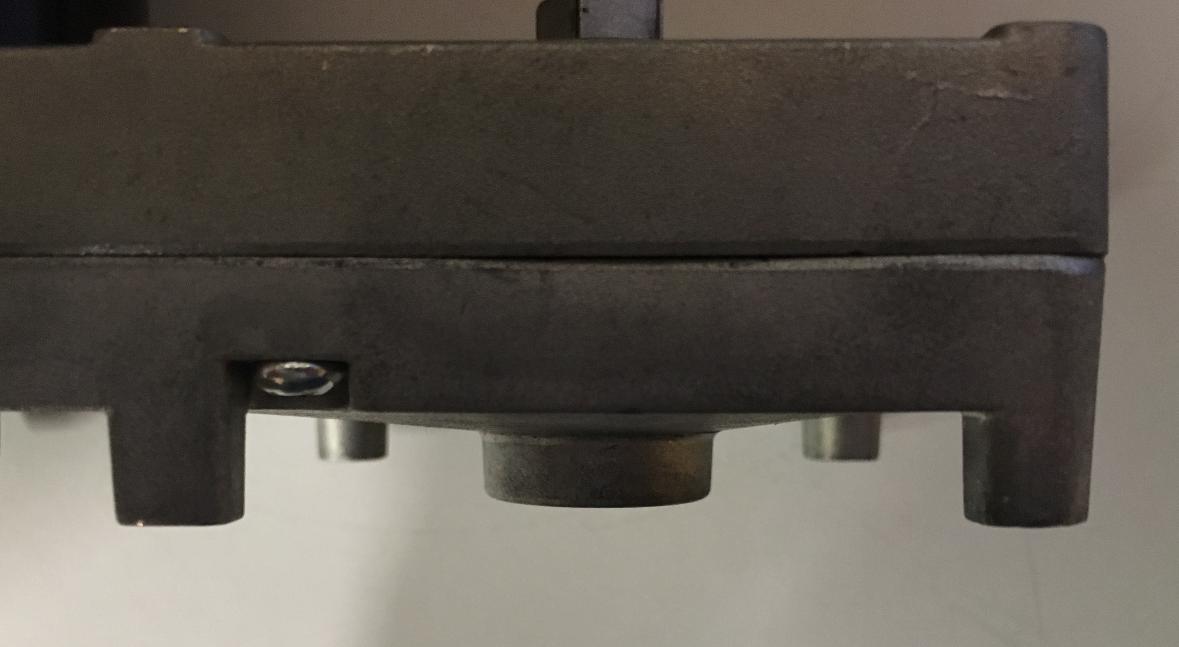

While running it at 180 and putting a teaspoon of pellets in, I noticed that I could see some pellets stationary in the barrel. They were under the auger, right at the barrel cut for the hopper (which is of course where I could see the pellets from). Seemed like that was an issue to me.

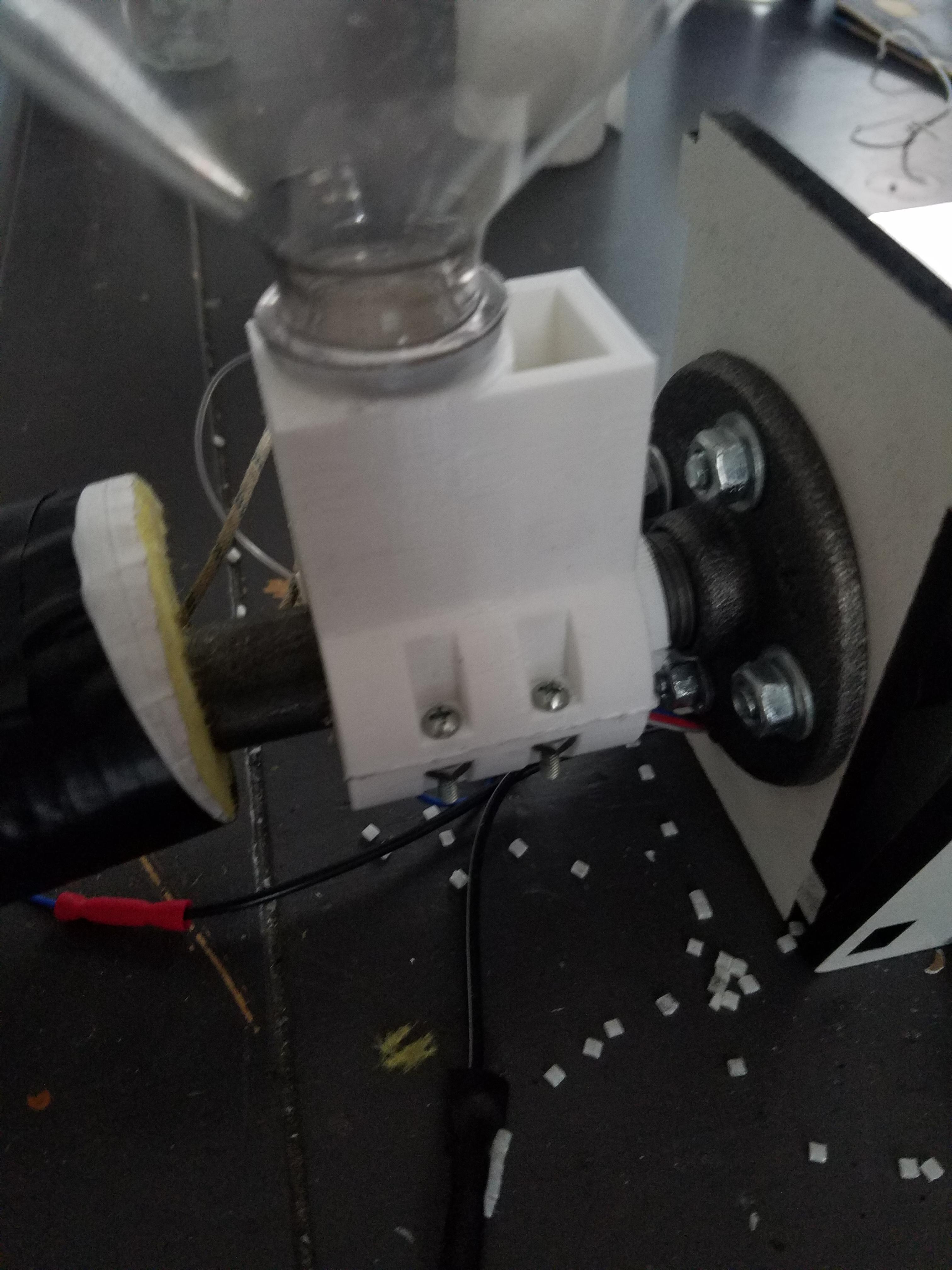

If I were to go to hobby lobby or something and get wiring specifically for this project, what would I be looking for? At this point I can only think that the stall prevention board is being funky because my wiring is a hackjob and having loss somewhere. So I'm going to start fresh yet again and see if that works as my final resort. Out of ideas